Assembling method and device for wiring terminal

A terminal block and assembly equipment technology, which is applied in connection, contact manufacturing, circuit/collector components, etc., can solve the problems of complex structure and difficulty in automatic production, and achieve increased storage capacity, simple and efficient structure, and improved detection Effect of Accuracy and Service Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

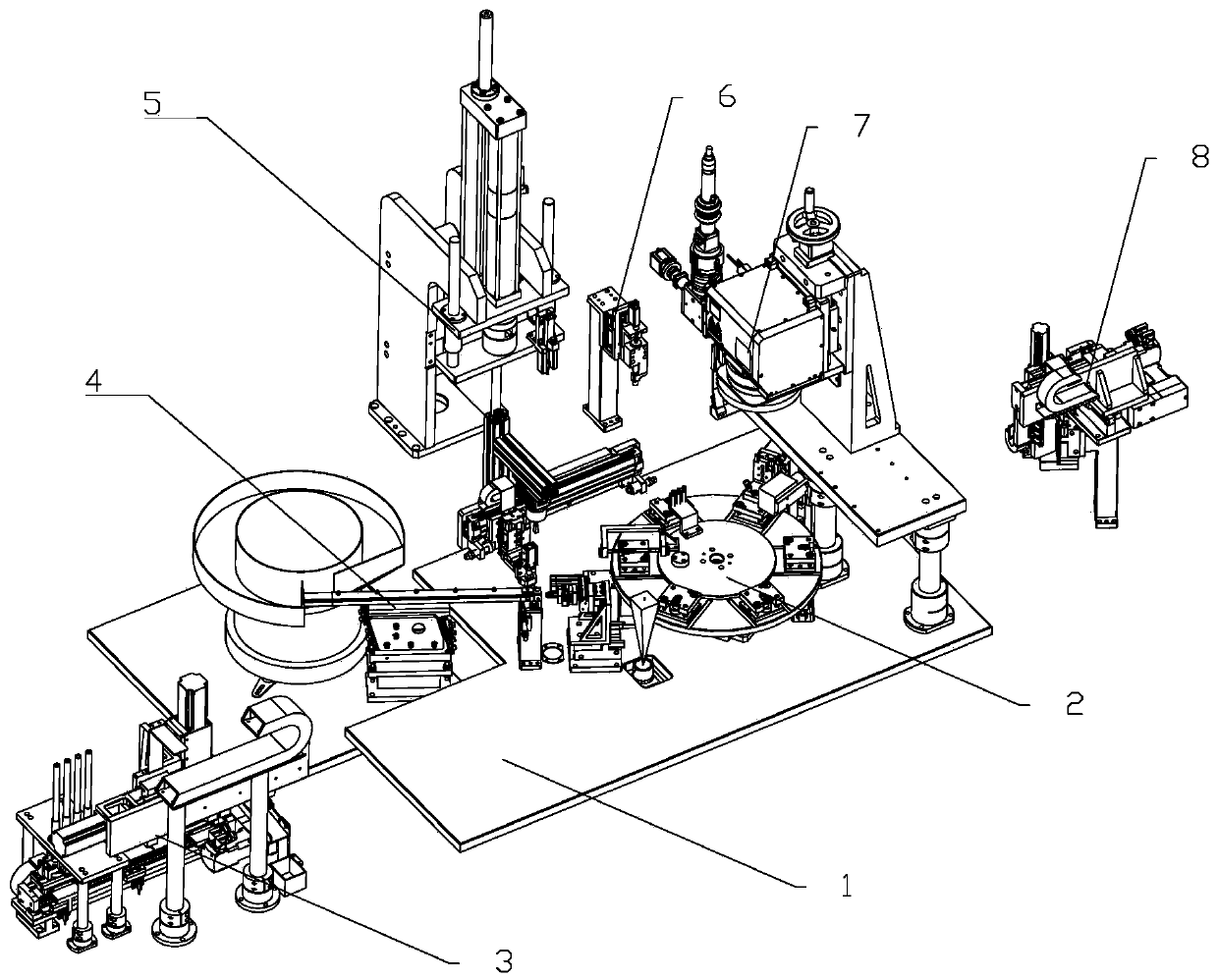

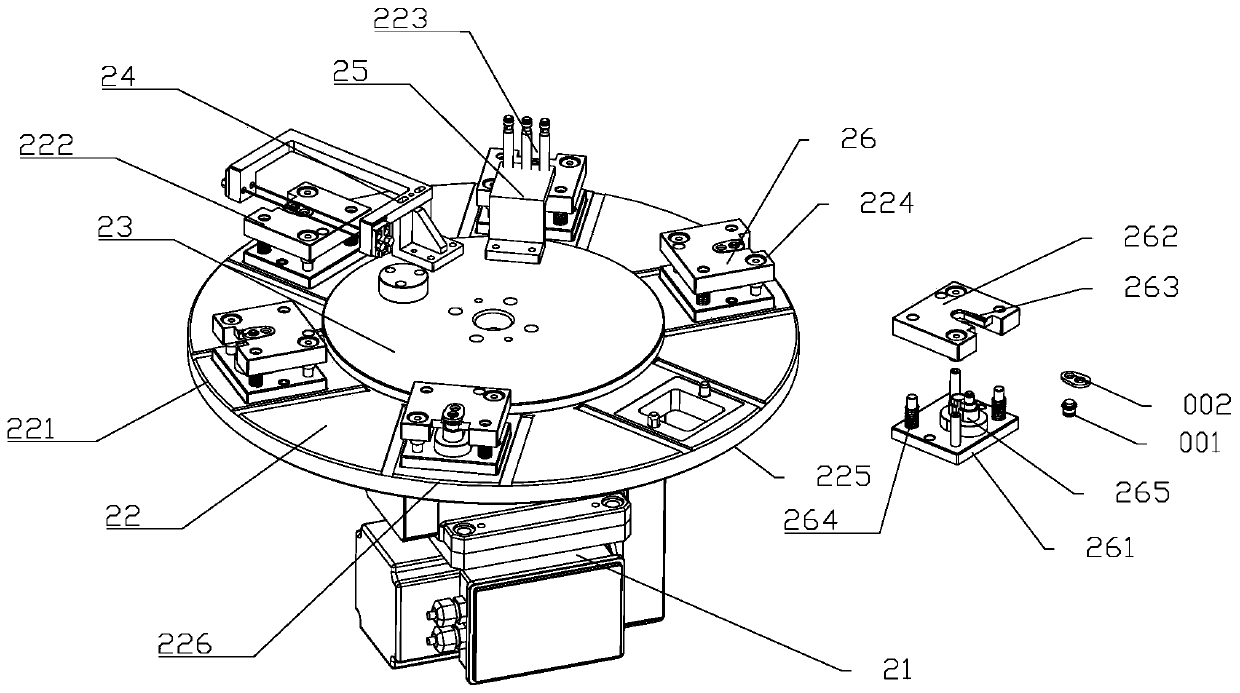

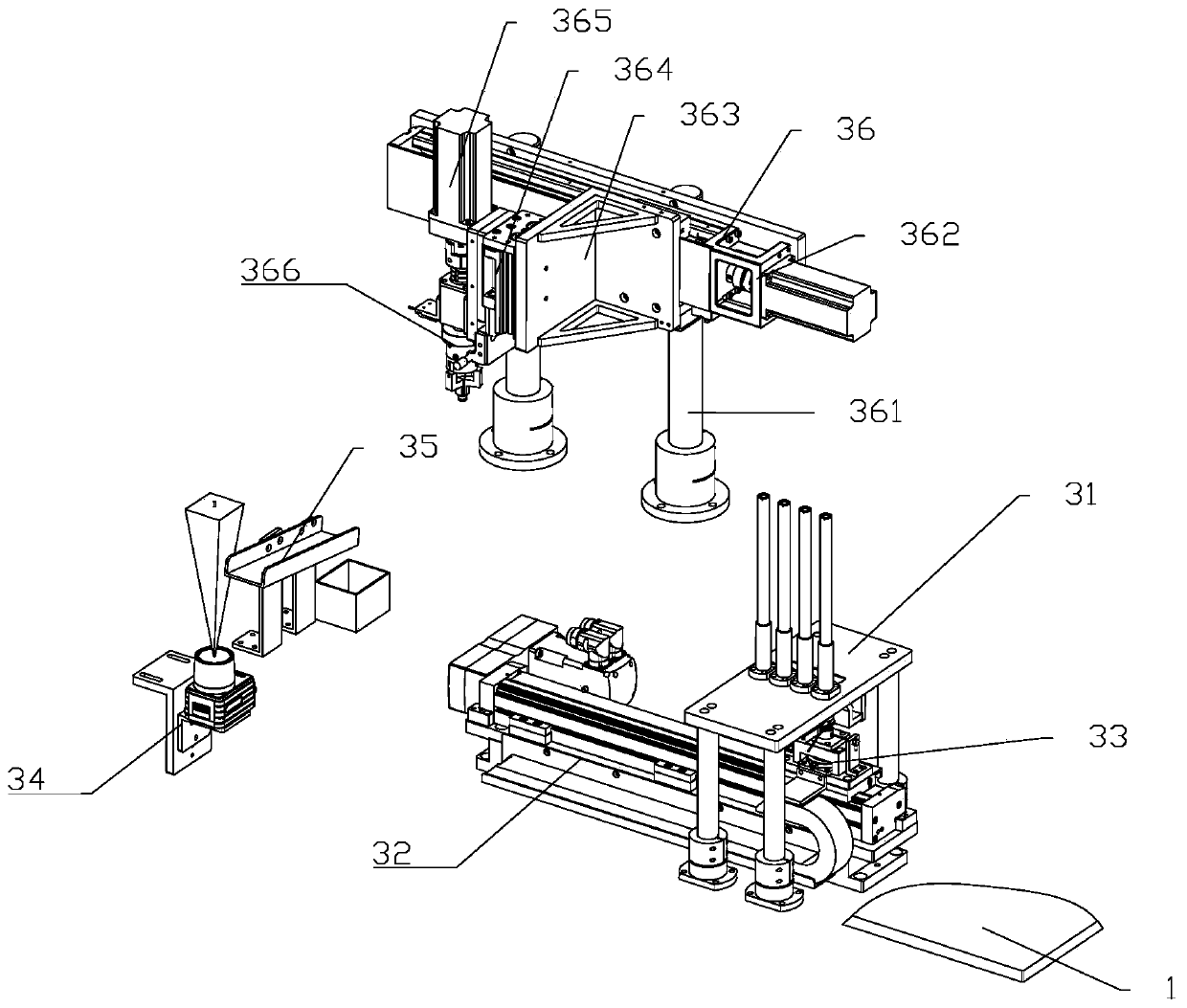

[0029] like figure 1 As shown, an assembly equipment for terminal blocks includes a frame 1 and a turntable device 2 installed on the frame 1, a metal column feeding device 3, a metal sheet feeding device 4, a pressing device 5, a height detection device 6, Laser welding device 7 and crack detection device 8; Turntable device 2 is provided with a plurality of fixtures, along the processing direction, metal column feeding device 3, metal sheet feeding device 4, press-fitting device 5, height detection device 6, laser The welding device 7 and the crack detection device 8 are successively connected around the turntable device 2 .

[0030] The turntable device 2 is used for conveying and processing workpieces, and the metal column feeding device 3 is used for separating a single metal column, and sorting and transporting the metal column to the jig; the metal sheet feeding device 4 is used for separating The metal sheets that come out are detected, and the qualified ones are trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com