Rubber tapping machine

A technology of rubber tapping machine and rubber tapping, which is applied in forestry, application, agriculture and other directions, can solve the problems of limit column breakage, damage, detachment of tool holder assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

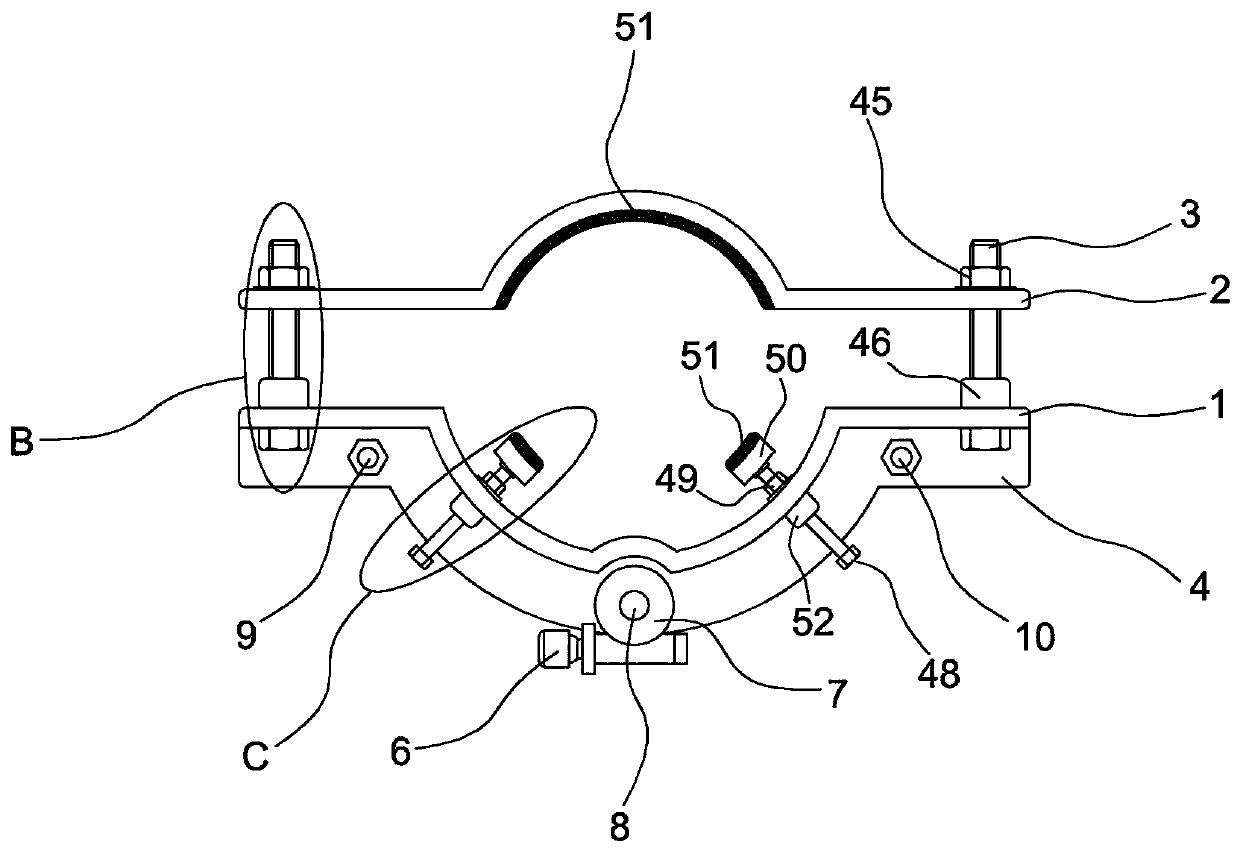

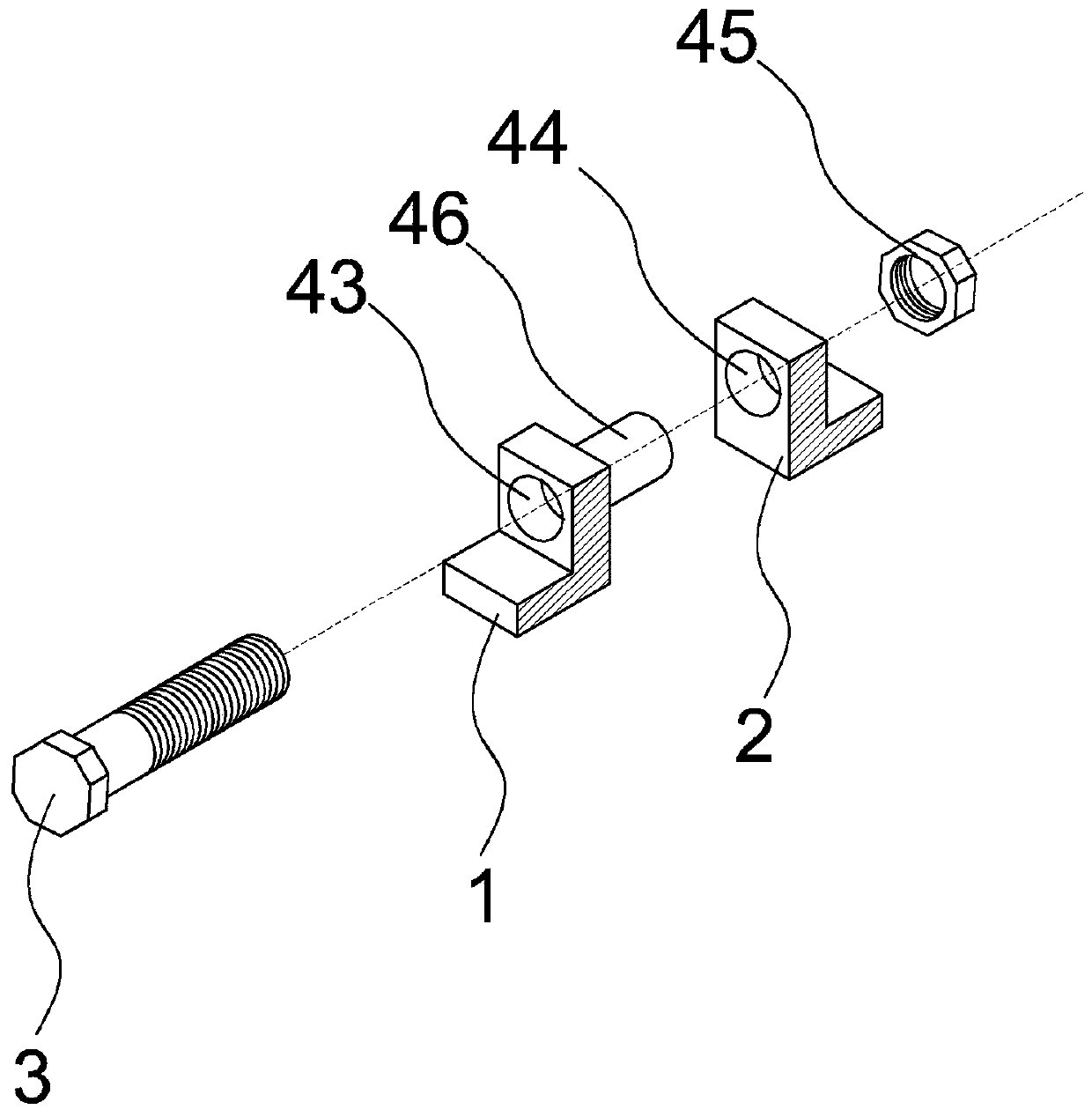

[0022] Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9As shown, a rubber tapping machine includes a first arc-shaped frame 1 and a second arc-shaped frame 2, and a first arc-shaped frame is arranged between the first arc-shaped frame 1 and the second arc-shaped frame 2 to connect the two together. The bolt 3 is clamped between the first arc-shaped frame 1 and the second arc-shaped frame 2, the first arc-shaped frame 1 is provided with an upper fixing segment 4, and the first arc-shaped frame 1 is provided with a lower fixing segment 5, The worm gear screw lifter 7 with the first motor 6 is arranged on the upper surface of the upper fixed section 4, and the worm gear screw lifter 7 is provided with a screw 8, and the first sliding rod 9 and the second sliding rod 10 are respectively fixed on the upper fixing segment 4 and the lower fixed section 5, the first sliding rod 9 is provided with a short sleeve 11, the second ...

Embodiment 2

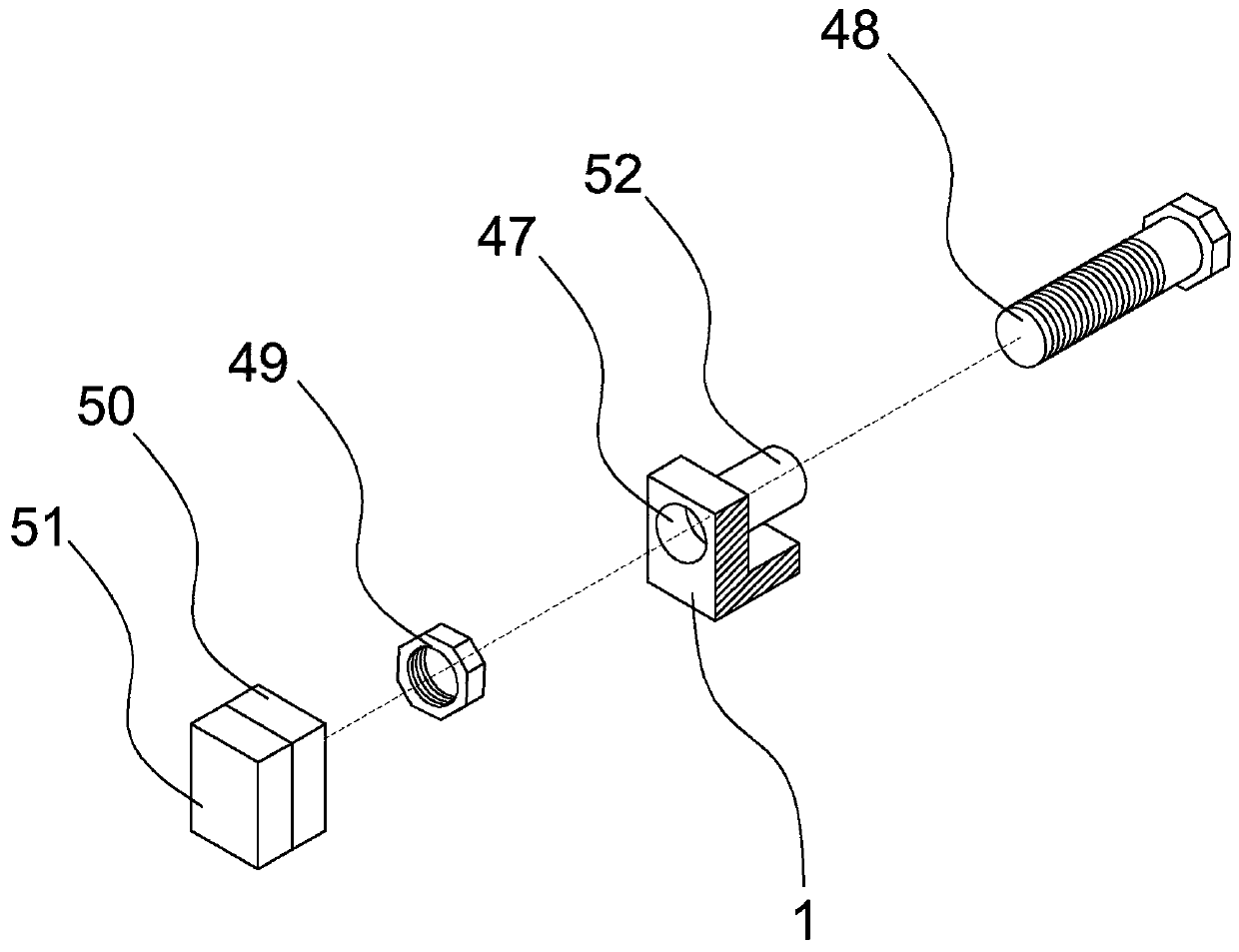

[0029] Example 2, such as figure 1 and image 3 As shown, the first arc-shaped frame 1 is provided with a fourth fixing hole 47, the fourth fixing hole 47 is provided with a second bolt 48, the inner surface of the first arc-shaped frame 1 is provided with a second nut 49, and the second nut 49 is connected to the second bolt 48, the fixing plate 50 is arranged at one end of the second bolt 48, and the fixing plate 50 and the second arc frame 2 are in a clamping state. Because rubber trees have different growth degrees and have different cross-sectional diameters, this rubber tapping machine can adjust the distance between the fixing plate 50 and the second arc frame 2 by rotating the second bolt 48 to adapt to rubber trees of different sizes. Ensure that the fixed plate 50 and the second arc-shaped frame 2 can clamp the trunk of the rubber tree mutually. After the distance between the fixed plate 50 and the second arc-shaped frame 2 has adapted to the cross-sectional diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com