Fully-automatic appearance inspection machine

A fully automatic and inspection machine technology, applied in sorting and other directions, can solve the problems of insufficient design, inability to do multi-angle, high cost, etc., and achieve the effect of improving work efficiency, ensuring product quality, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be further described below in combination with specific embodiments.

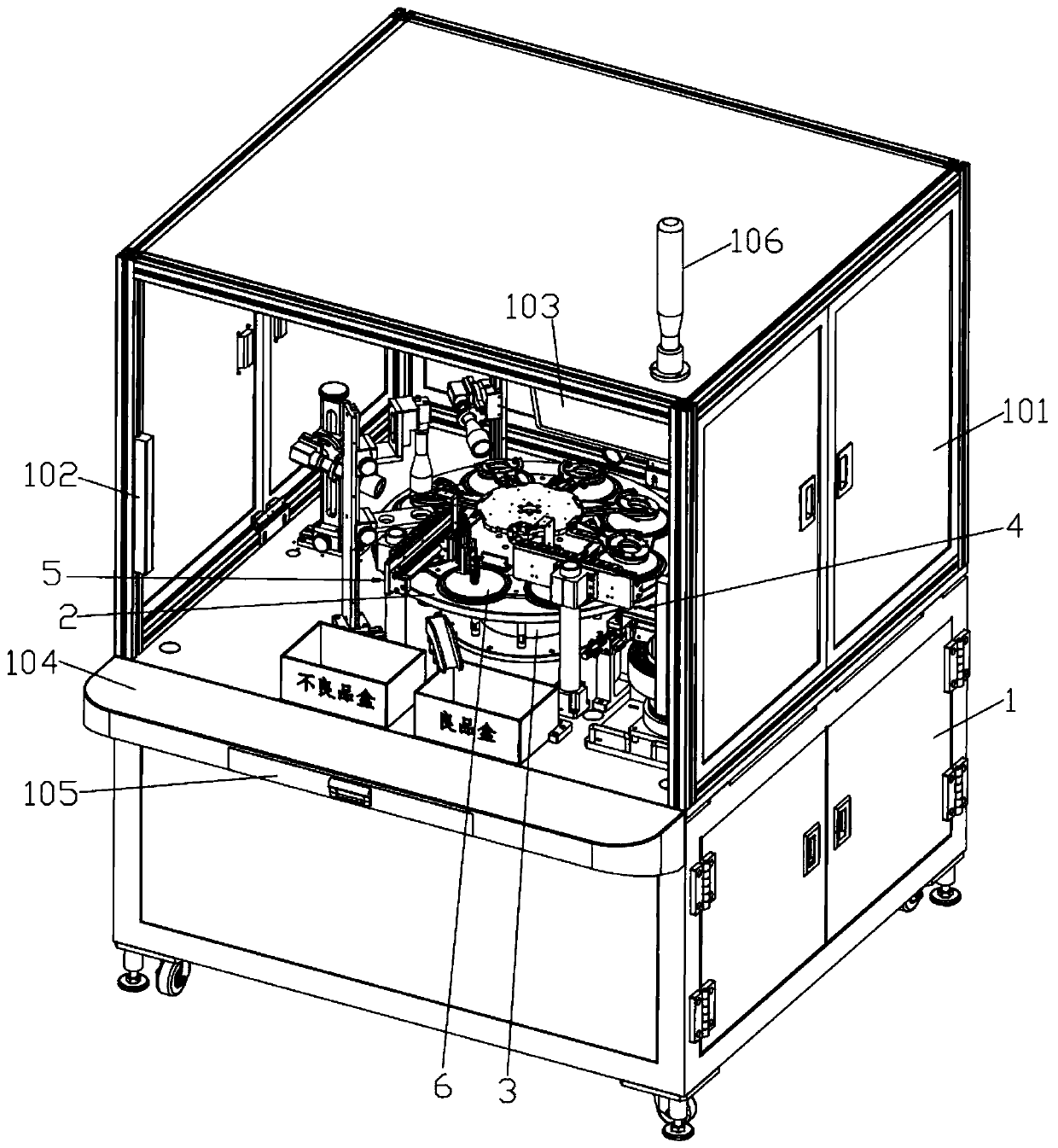

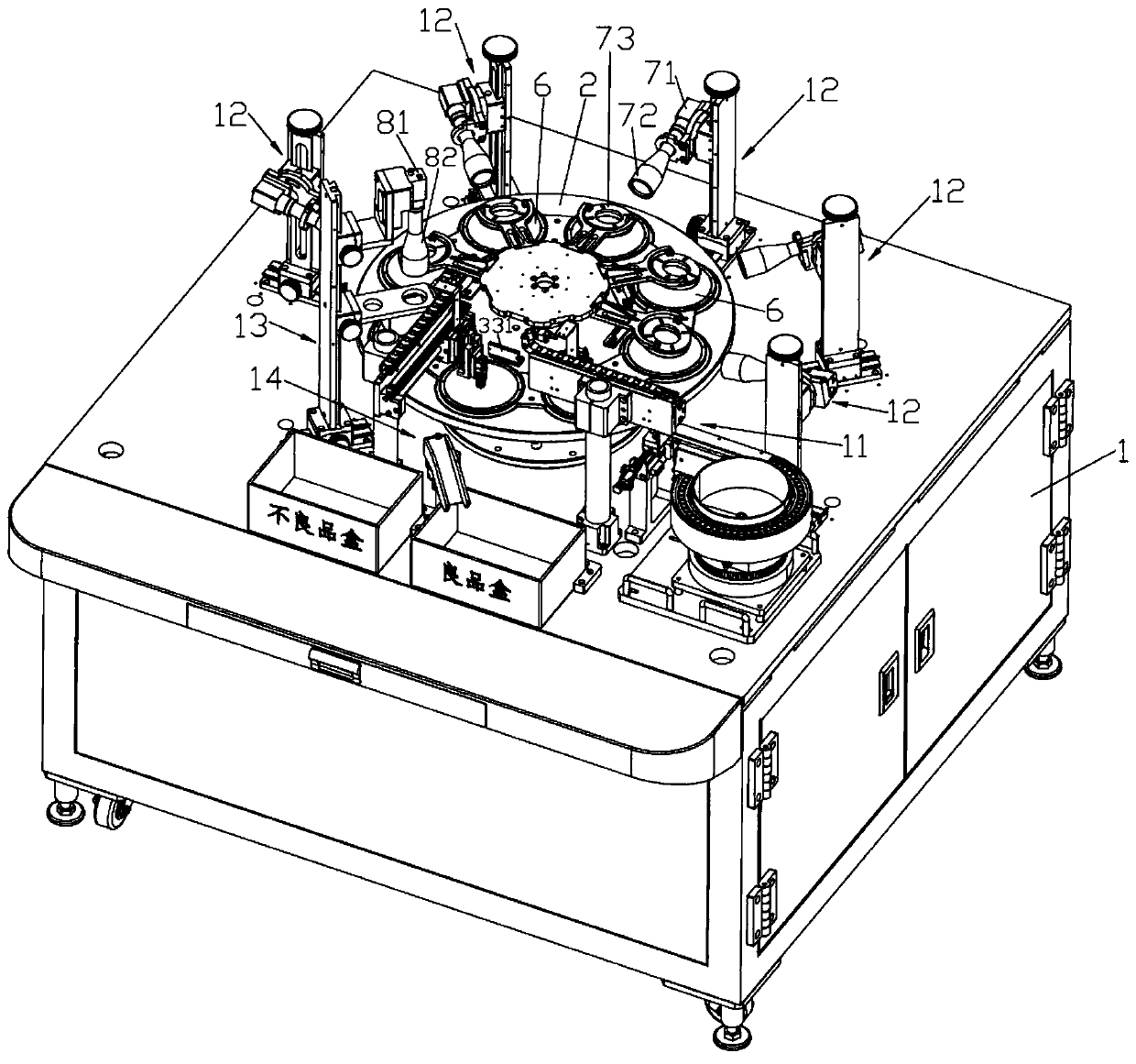

[0023] like figure 1 and 2 As shown, the fully automatic appearance inspection machine according to one embodiment of the present invention includes a frame 1 , a turntable 2 , a turntable power unit 3 , a feeding mechanism 4 and a feeding mechanism 5 .

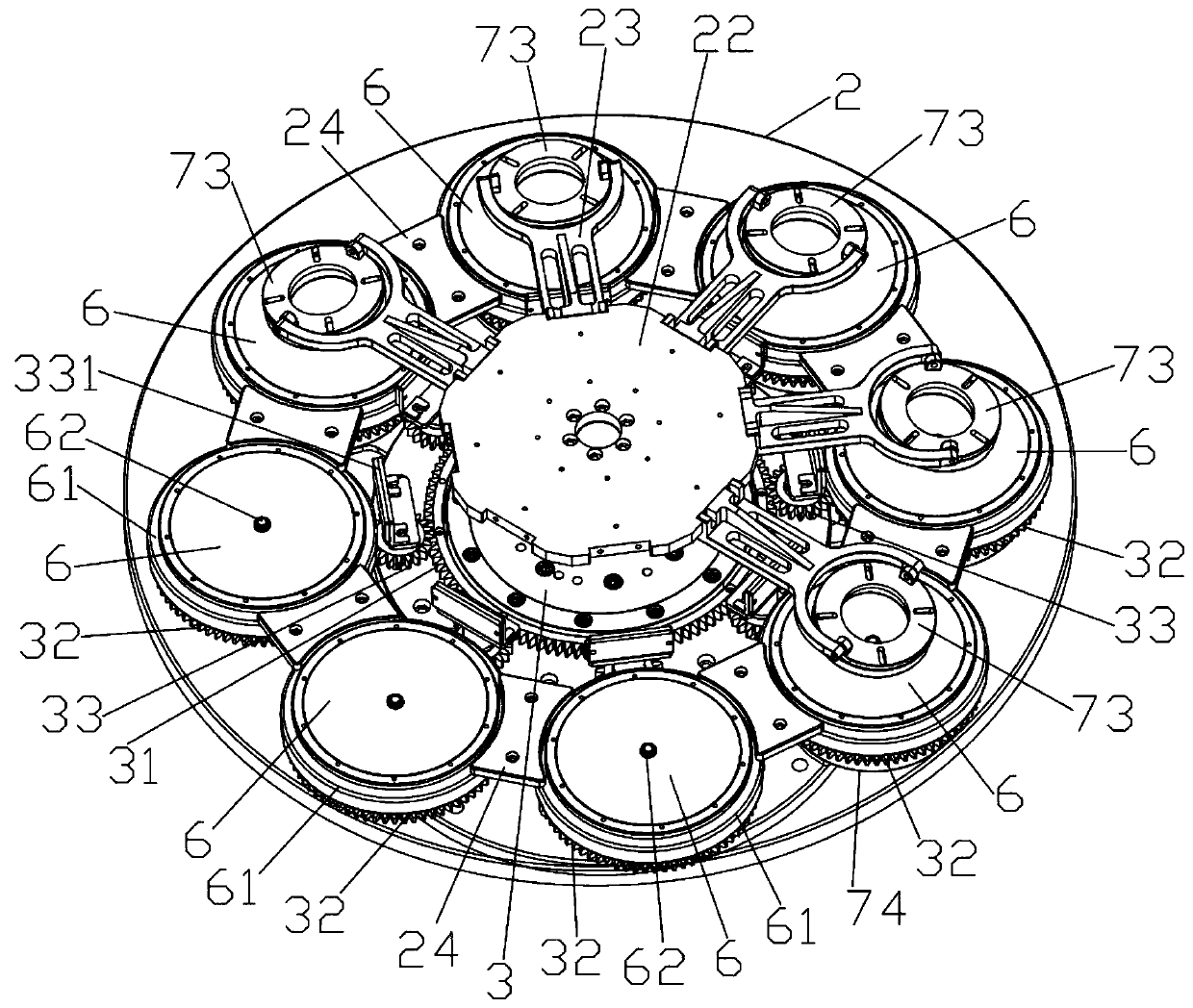

[0024] like image 3 As shown, the turntable 2 adopts a hollow disc, and the turntable power device 3 adopts a DD motor, that is, a direct drive motor, and the center of the direct drive motor has a through hole. The bottom of the turntable power unit 3 is installed on the frame 1, and the top of the turntable power unit 3 is equipped with a main gear 31 through bolts, and the turntable 2 is installed on the end face of the turntable power unit 3 through bolts. The direct drive motor can be directly connected to the load, that is, the turntable 2 and the main gear 31. It has low energy consumption, high efficiency, low n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com