Powder metallurgy sintering device

A sintering device and powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of small amount of stored materials, inconvenient collection and transportation of materials, inconvenient exhaust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings:

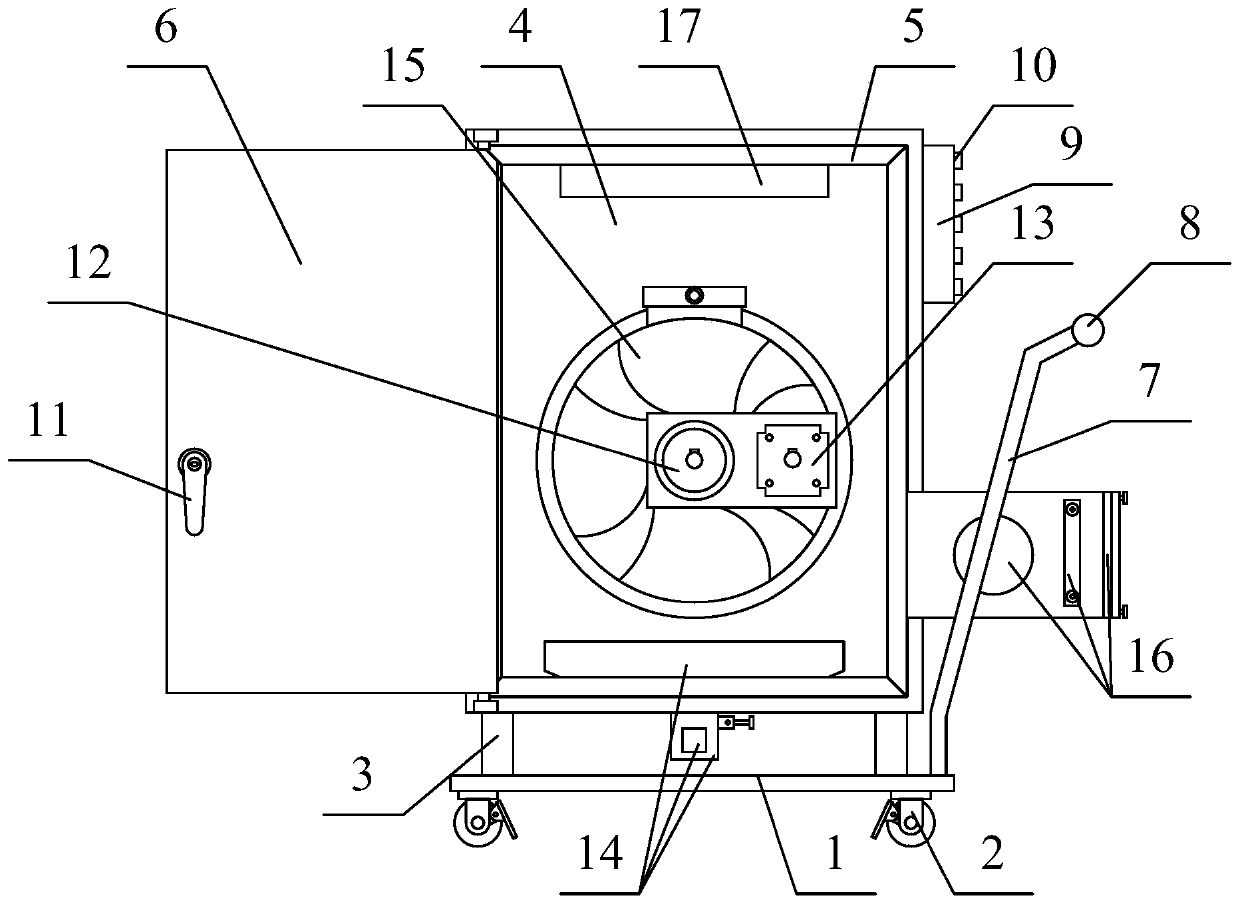

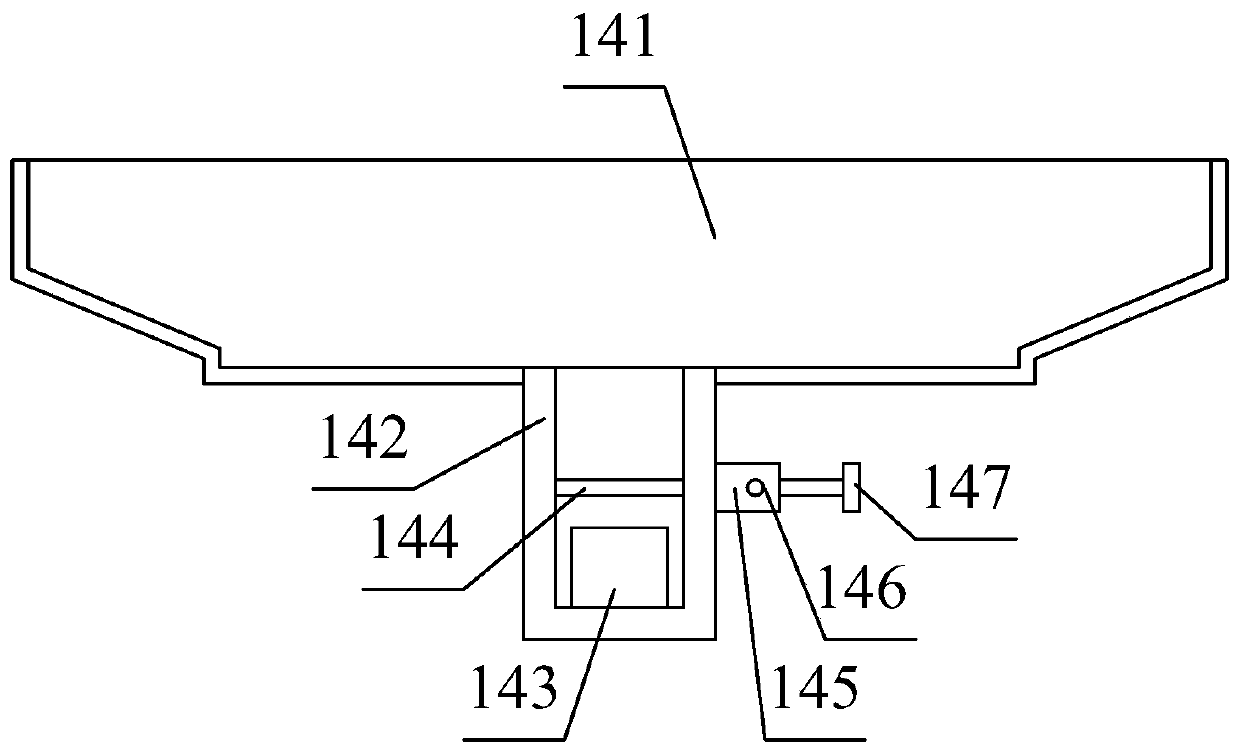

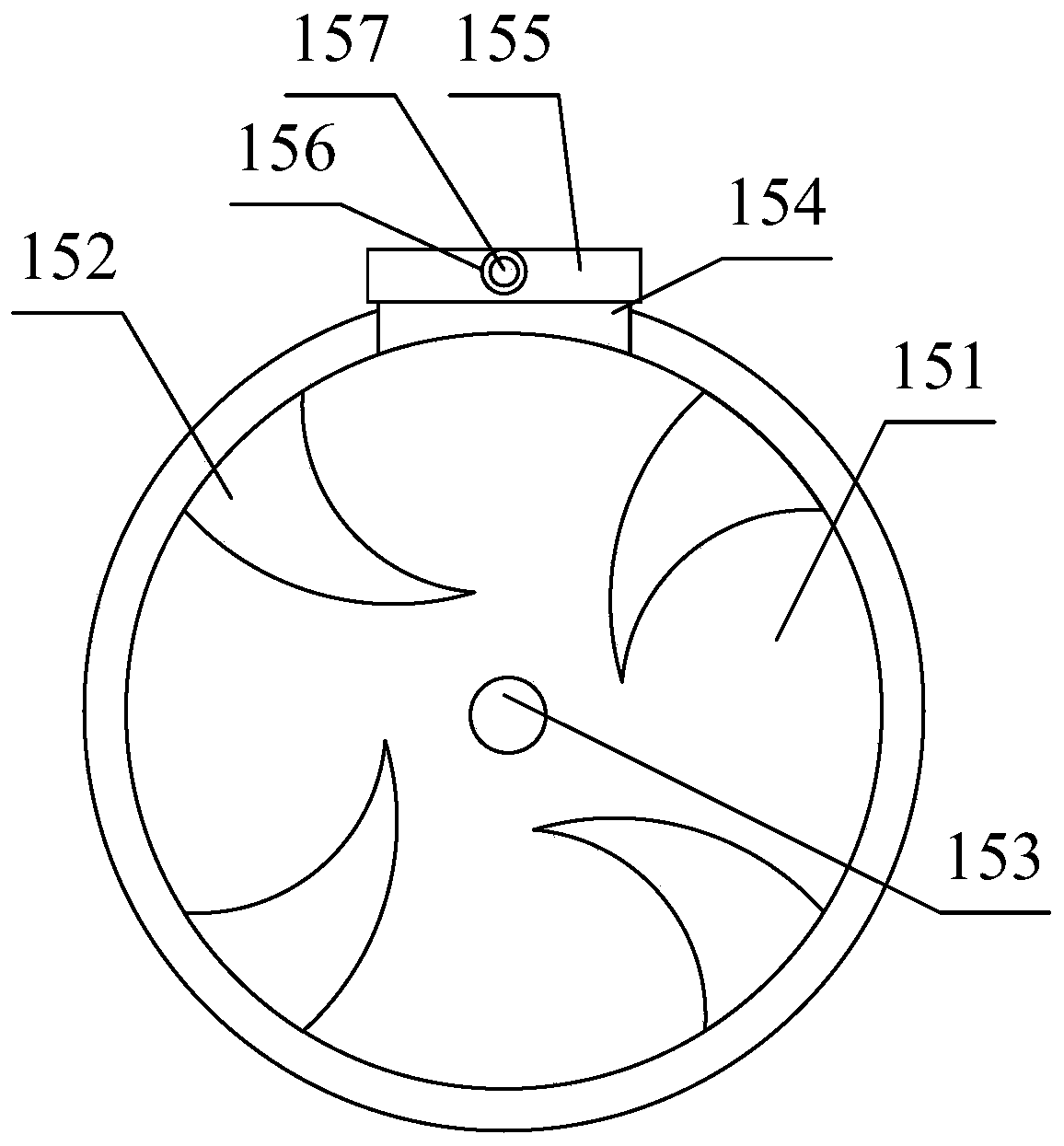

[0034] As attached figure 1 And figure 2 As shown, a powder metallurgy sintering device according to the present invention includes a base 1, a moving wheel 2, a supporting column 3, a box body 4, a side guard 5, a box door 6, a connecting rod 7, a gripping rod 8, a PLC9, Switch 10, handle 11, reducer 12, rotating motor 13, collecting and conveying hopper structure 14, rotating heating box structure 15, exhaust pipe structure 16 and heating pipe 17, the moving wheels 2 are respectively bolted to the lower surface of the base 1 The support column 3 is welded around the upper surface of the base 1; the box body 4 is welded to the upper end of the support column 3; the edge protection 5 is welded to the front of the inner wall of the box body 4; The box door 6 is axially connected to the left side of the front part of the inner wall of the box body 4, and is arranged at the front part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com