Multi-degree-of-freedom end executer for tool changing robot

An end effector and degree of freedom technology, applied in the direction of manipulators, collets, manufacturing tools, etc., can solve the problems of low tool change efficiency and single tool change function, and achieve the effects of improving work efficiency, flexible movement, and increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

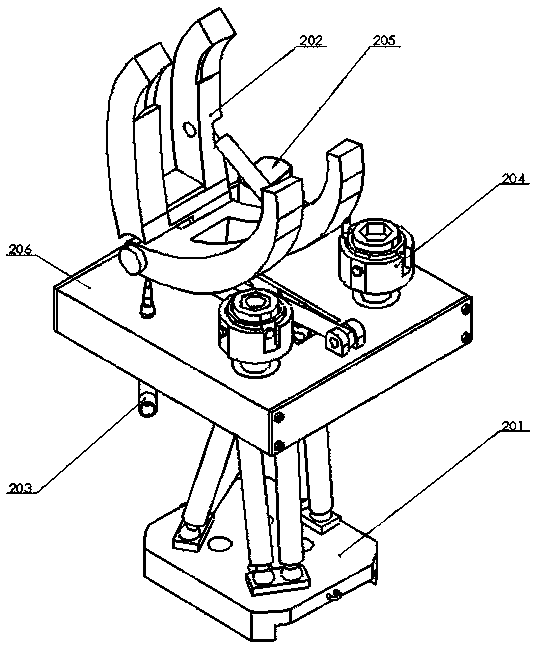

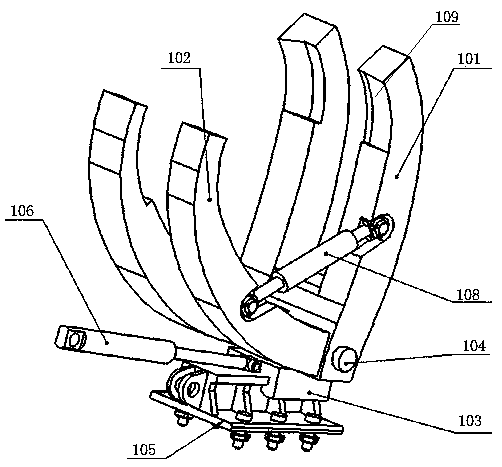

[0034] Example 2, such as image 3 As shown, a multi-degree-of-freedom end effector for a tool changing robot, the clamping mechanism 202 includes a fixed claw 101 and a movable claw 102, the movable claw 102 is hinged to the fixed claw 101 and is opened and closed by a clamping cylinder 108, namely Under the expansion and contraction of the clamping oil cylinder, the movable claw moves relative to the fixed claw to realize whether the tool is grasped or not. The top of the fixed claw 101 is connected with the sliding drive mechanism. Under the action of the sliding drive mechanism, the fixed claw and the movable claw can slide and translate to realize the change of their positions, so as to adapt to the disassembly and replacement of tools in different positions.

[0035] Preferably, the sliding drive mechanism includes a guide rail 105, the guide rail 105 is fixed in the connecting box 206, a slider 103 is slid on the guide rail 105, the slider 103 is fixedly connected with t...

Embodiment 3

[0037] Example 3, such as Figure 4 As shown, a multi-degree-of-freedom end effector for a tool changing robot, the high-pressure cleaning mechanism 203 includes a nozzle joint 302 and an interface pipe 303, the nozzle joint 302 is sleeved in the interface pipe 303 and passes through the connecting box 206 upwards, The nozzle joint 302 is tightly connected with the interface pipe 303 , and the nozzle joint 302 can move up and down with the interface pipe 303 to realize the expansion and contraction of the nozzle joint 302 . The upper part of the nozzle joint 302 is provided with a high-pressure nozzle 301, and the interface pipe 303 is fixed inside the connection box 206 and connected with an external water source. The external water source enters the nozzle joint through the interface pipe, and then sprays out through the high-pressure nozzle to clean the designated tool for easy disassembly.

[0038] Preferably, as Figure 5 As shown, the two sides of the nozzle joint 302 ...

Embodiment 4

[0042] Example 4, such as Figure 8 As shown, a multi-degree-of-freedom end effector for a tool changing robot, the bolt tightening mechanism 204 includes a torque driver 401, a torque wrench 404 and a flexible end mechanism 406, the torque driver 401 connects with the torque wrench 404 through a link mechanism 402 The torque driver 401, the linkage mechanism 402 and the torque wrench 404 are located in the connection box 206, one end of the torque driver 401 is fixed on the connection box, and the torque driver can be a hydraulic cylinder. The flexible end mechanism 406 protrudes from the connection box 206, and one end of the torque wrench 404 is connected to the flexible end mechanism 406, and the torque driver drives the torque wrench to rotate through the linkage mechanism. The torque driver 401 drives the flexible end mechanism 406 to rotate through the link mechanism 402 and the torque wrench 404 . When in use, the flexible end mechanism blocks the bolt on which the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com