Transfer film pasting device for jointed board

A paste device, transfer film technology, applied in the direction of metal processing, etc., can solve the time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

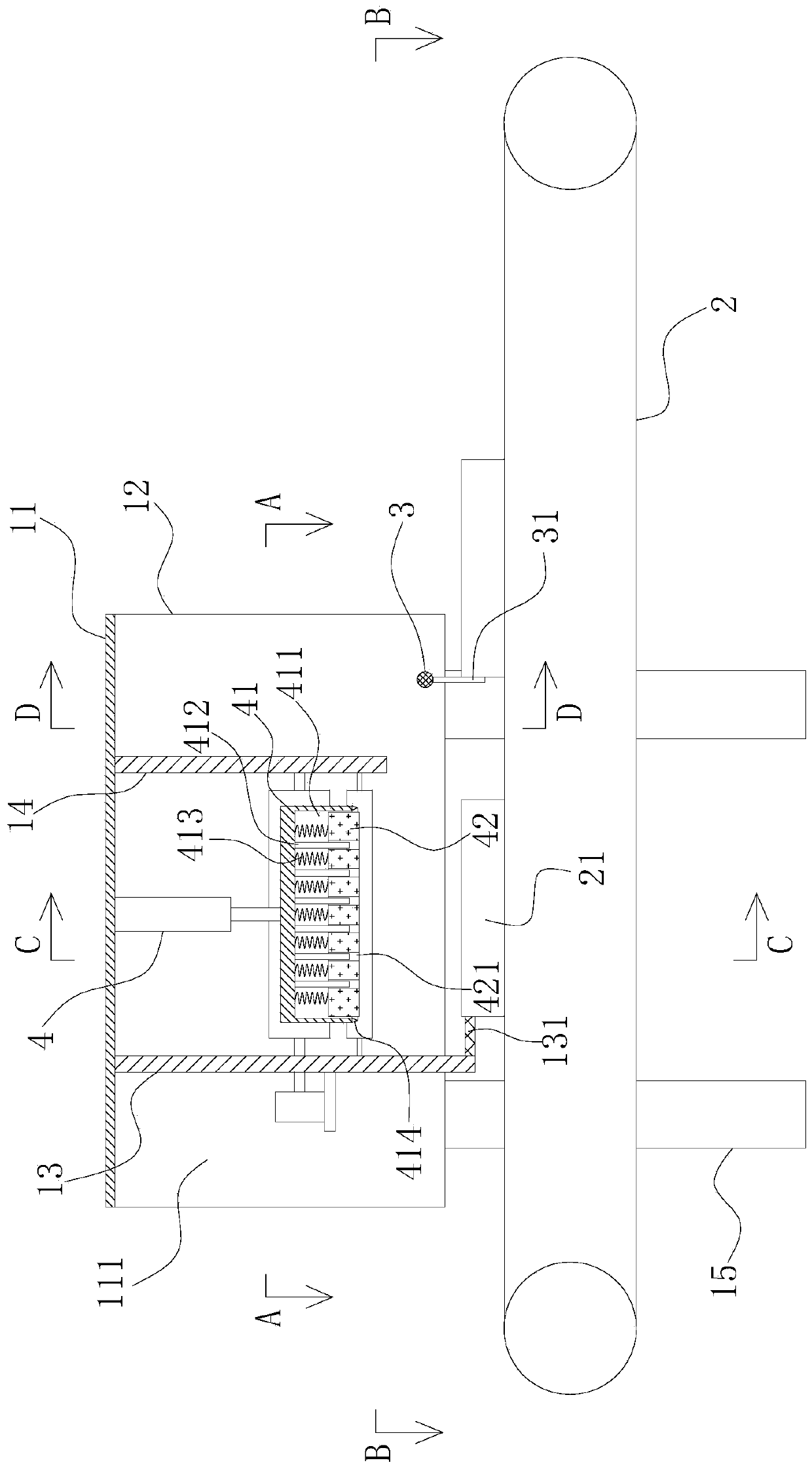

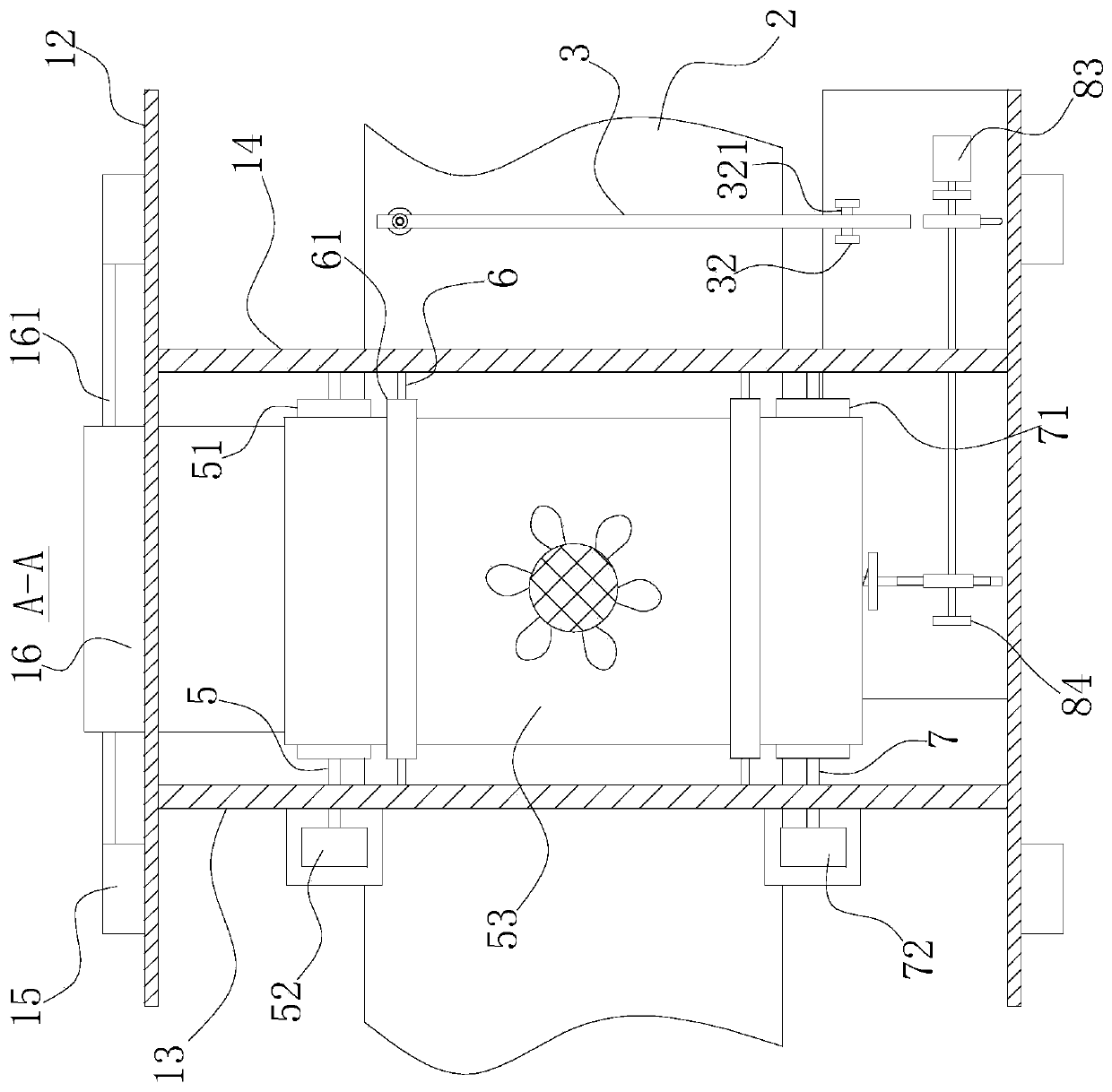

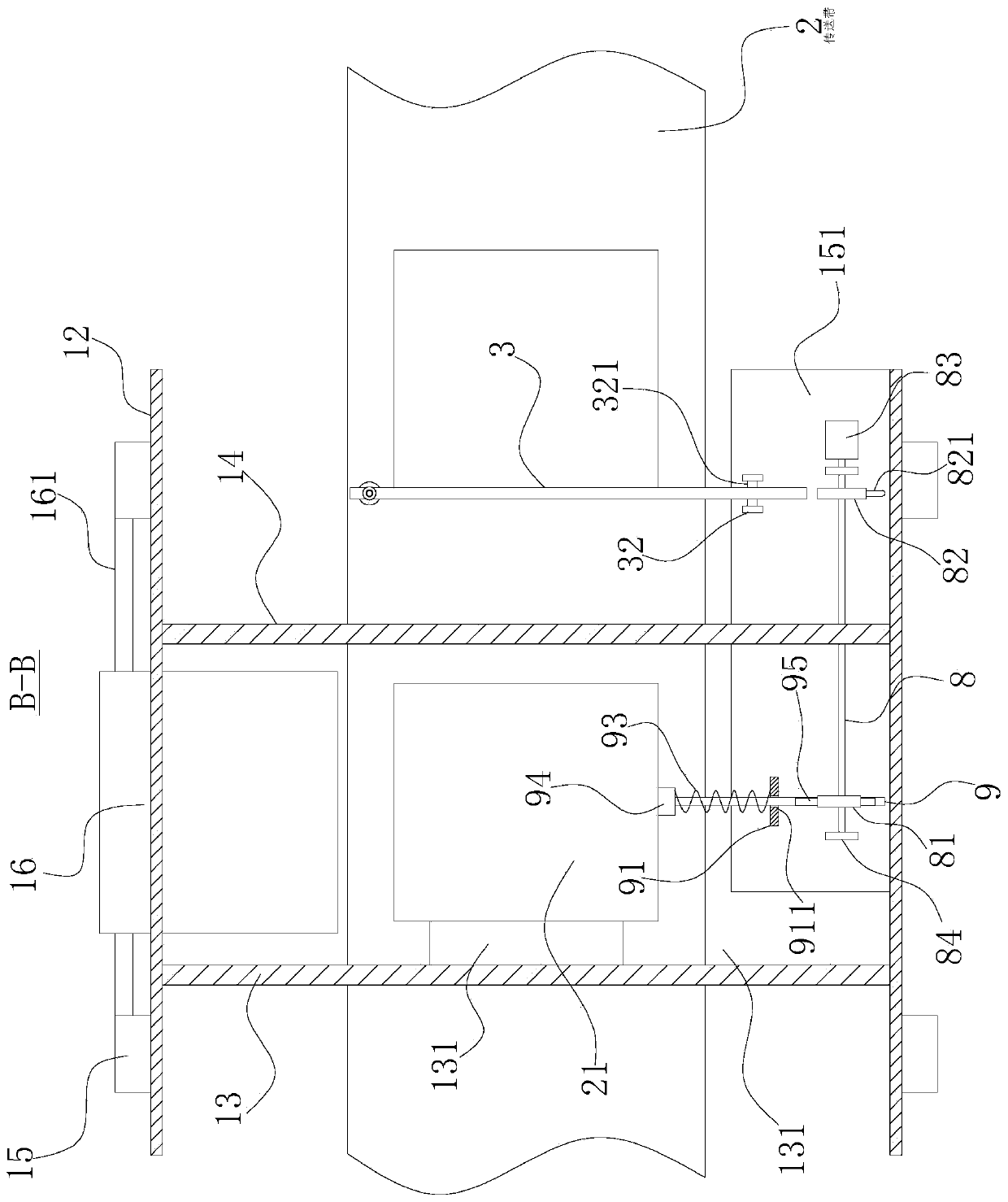

[0064] Such as Figures 1 to 7 As shown, a transfer film sticking device used for panelization includes: a top plate 11, two side plates 12, a first conveyor belt 2, a second partition 14, a first partition 13, a transfer film conveying mechanism, Cutting mechanism, pasting mechanism, pushing mechanism and blocking mechanism.

[0065] The two side plates are respectively arranged on the front and rear edges of the lower side of the top plate 11, a pasting space 111 is formed between the top plate 11 and the two side plates 12, and the outer sides of the two side plates 12 are vertically arranged. There are two support legs 15 .

[0066] The first conveyor belt 2 is horizontally arranged directly below the pasting space 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com