Heavy truck tire detaching device

A technology for tire disassembly and heavy-duty trucks, applied in tire installation, tire parts, vehicle parts, etc., can solve the problems of a lot of effort, dangerous disassembly process, heavy weight, etc., to achieve the effect of convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

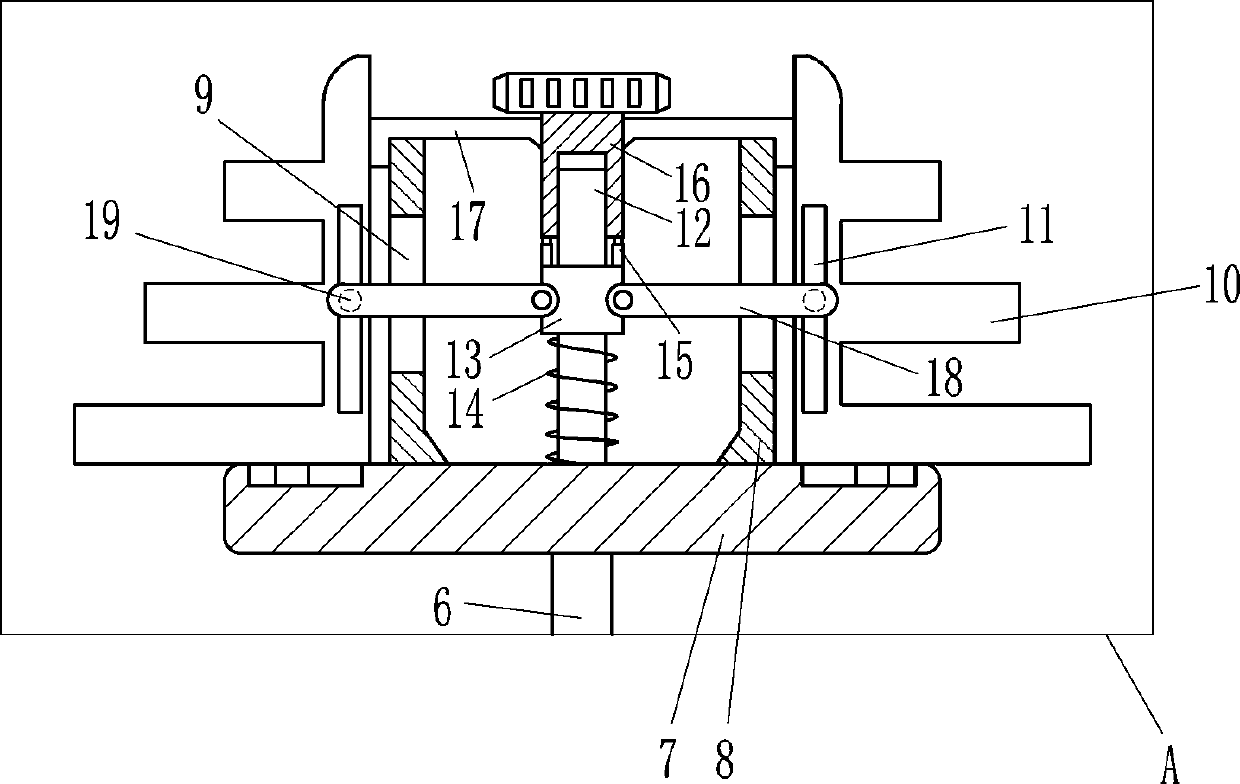

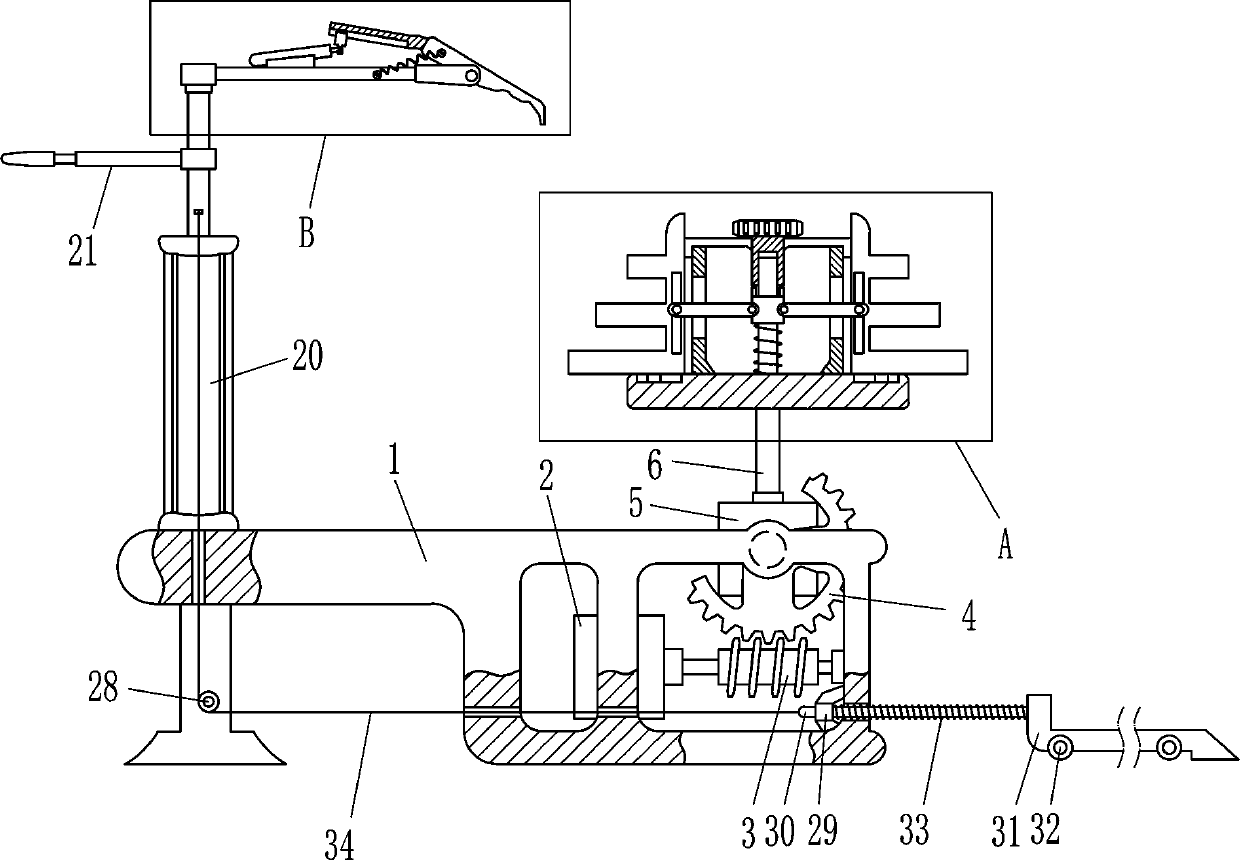

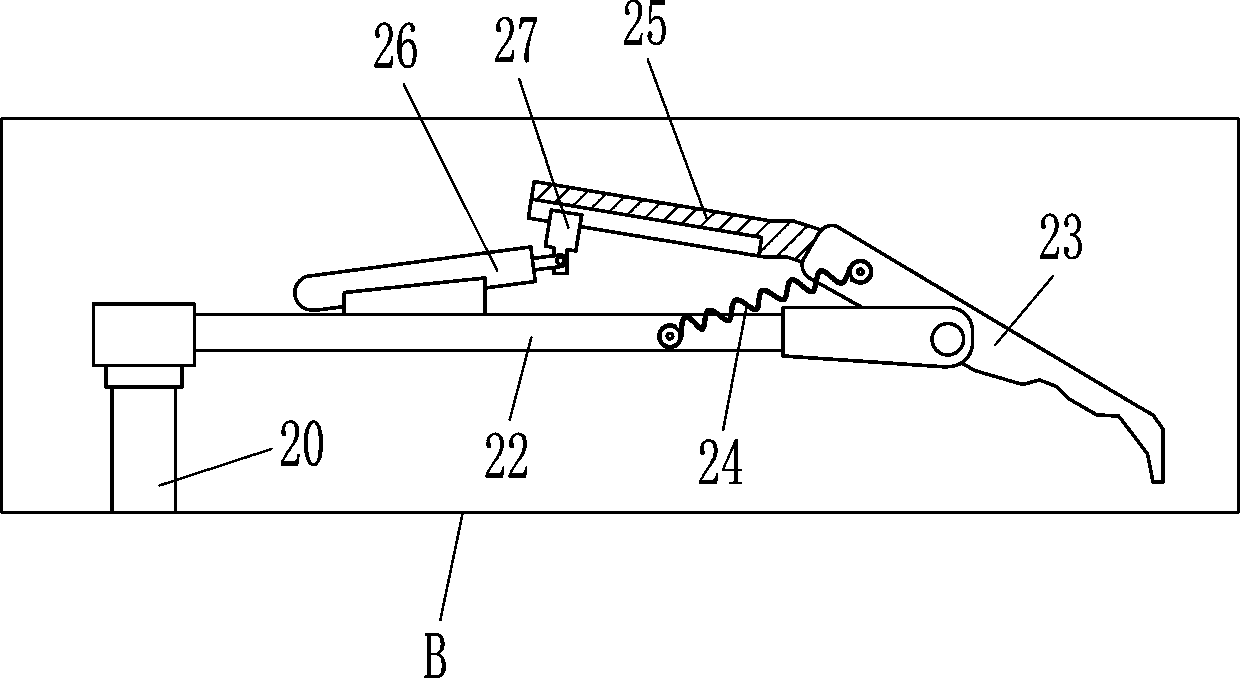

[0020] A heavy duty truck tire removal device such as Figure 1-3 As shown, it includes a frame 1, a hydraulic cylinder 20 and a telescopic compression rod 21. The hydraulic cylinder 20 is fixed on the left side of the top of the frame 1 by fastening bolts, and the telescopic compression rod 21 is rotatably installed on the telescopic parts of the hydraulic cylinder 20. Also includes:

[0021] Such as figure 1 As shown, the rotating part for tire angle adjustment by means of rotation is installed on the frame 1, and the rotating part includes a first reduction motor 2, a worm 3 and a worm wheel 4, and the first reduction motor 2 Installed on the right part of the frame 1 by fixing bolts, the worm 3 is connected to the output shaft of the first reduction motor 2 through a coupling, and the frame 1 above the worm 3 is rotatably equipped with a worm wheel 4;

[0022] Such as figure 1 As shown, the rotating part that drives the tire to rotate by means of rotation, the rotating ...

Embodiment 2

[0031] Such as figure 1 As shown, it also includes a pulley 28, a guide sleeve 29, a guide rod 30, a moving plate 31, a second elastic member 33 and a wire rope 34, the pulley 28 is installed on the left part of the frame 1, and the right part of the frame 1 is installed There is a guide sleeve 29, a guide rod 30 is slidably connected to the inside of the guide sleeve 29, a moving plate 31 is fixedly connected to the right end of the guide rod 30, and a second elastic member 33 is welded between the moving plate 31 and the guide sleeve 29 , the second elastic member 33 is an ordinary spring, gas spring, compression spring, etc., the second elastic member 33 is sleeved on the guide rod 30, and a steel wire rope 34 is connected between the telescopic part of the hydraulic cylinder 20 and the guide rod 30, and the steel wire rope 34 bypasses the pulley 28 and also includes wheels 32 mounted on the moving plate 31 .

[0032] In the specific operation process of the above embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com