Preparation method of fright fence accessories, fright fence parts blanks and semi-finished fright fence parts

A technology for semi-finished products and accessories, applied in textile and papermaking, knitting, weft knitting, etc., can solve the problems of time-consuming and laborious dismantling process, low knitting efficiency, large waste yarn consumption, etc. The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] A method for preparing fence accessories, the method is mainly used for mass production of wool fence accessories, which includes the following steps:

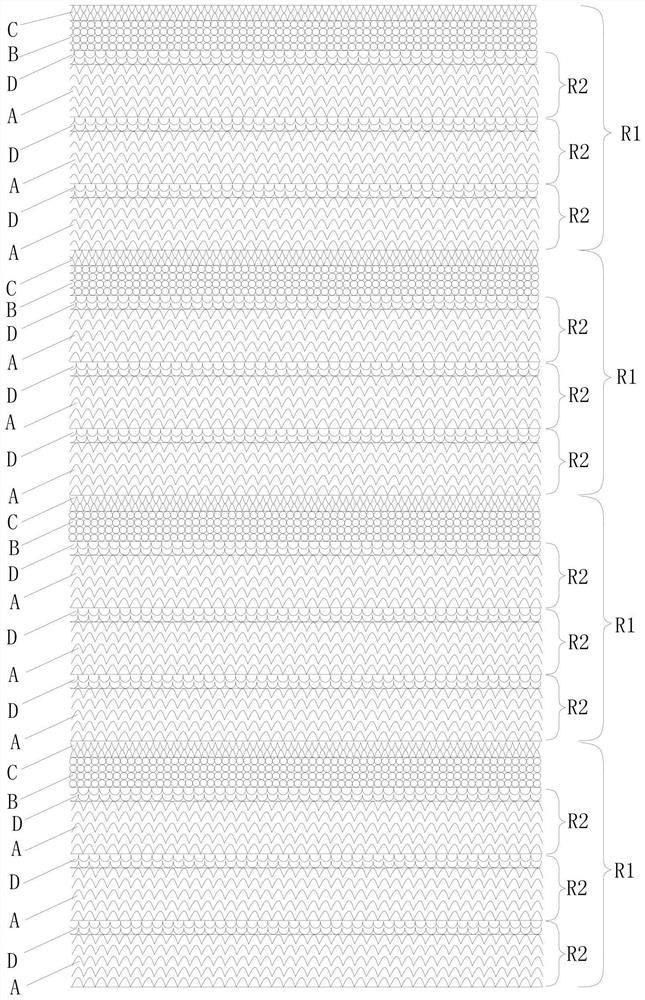

[0039] S1. According to the required number of fence accessories A, make knitting data in the computerized flat knitting system, and set the cycle number n value of the second cycle group R2 according to the size and height of the fence accessories A, and thus Determine the range of the first cyclic group R1, the first cyclic group R1=(A+D)*n+B+C;

[0040] S2. Import the determined range data of the first cycle group R1 into the computerized flat knitting machine, determine the main yarn material of the railing accessory A, select the PP thread as the first separation yarn C, and determine the water-soluble yarn as the second separation yarn D;

[0041] S3. According to the quantity of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com