Water tank garbage disposer

A garbage disposer and water tank technology, which is applied in water supply installations, buildings, and indoor sanitary plumbing installations, etc., can solve the problems that the water tank and garbage processor cannot be operated at the same time, garbage cannot be disposed of in time, water loss and waste, etc., to achieve Functional guarantee of safety and cutting, increased crushing effect, and effect of improving hygienic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

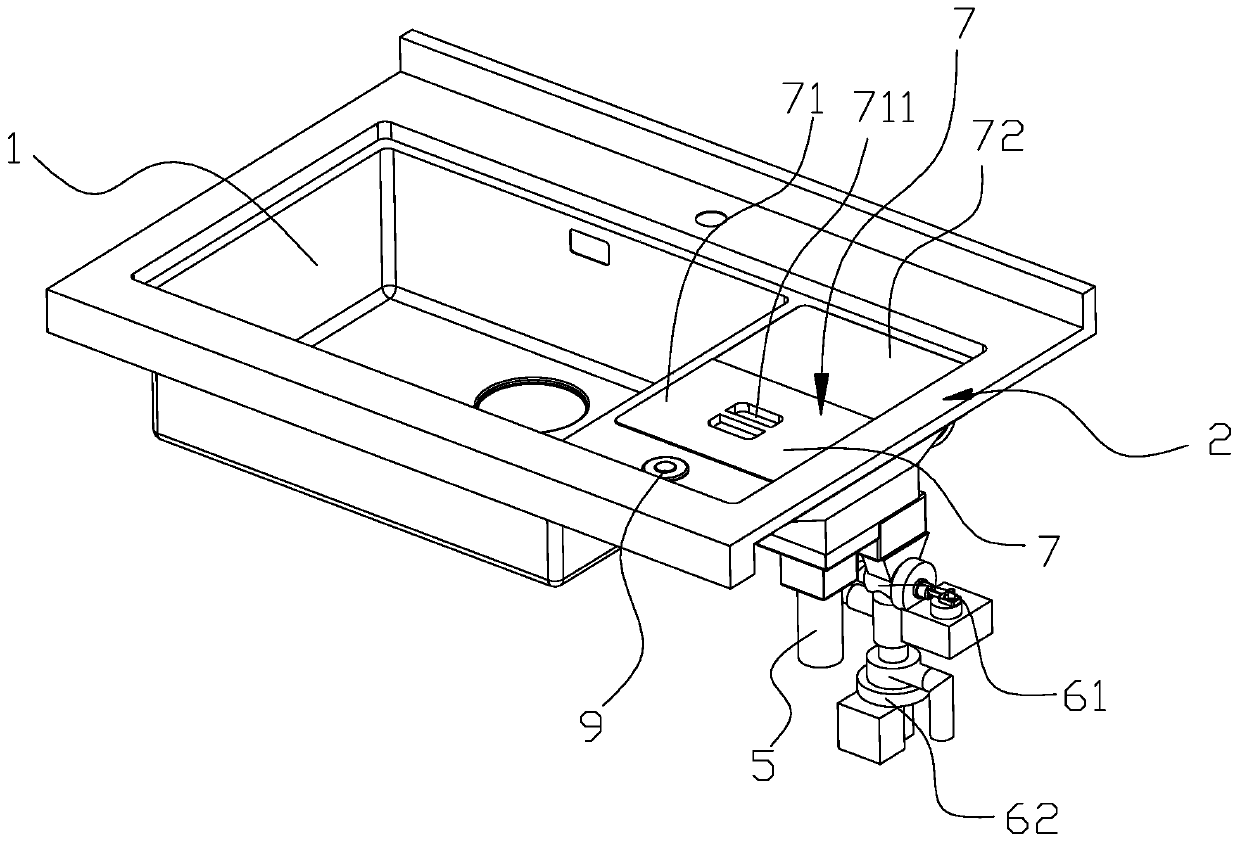

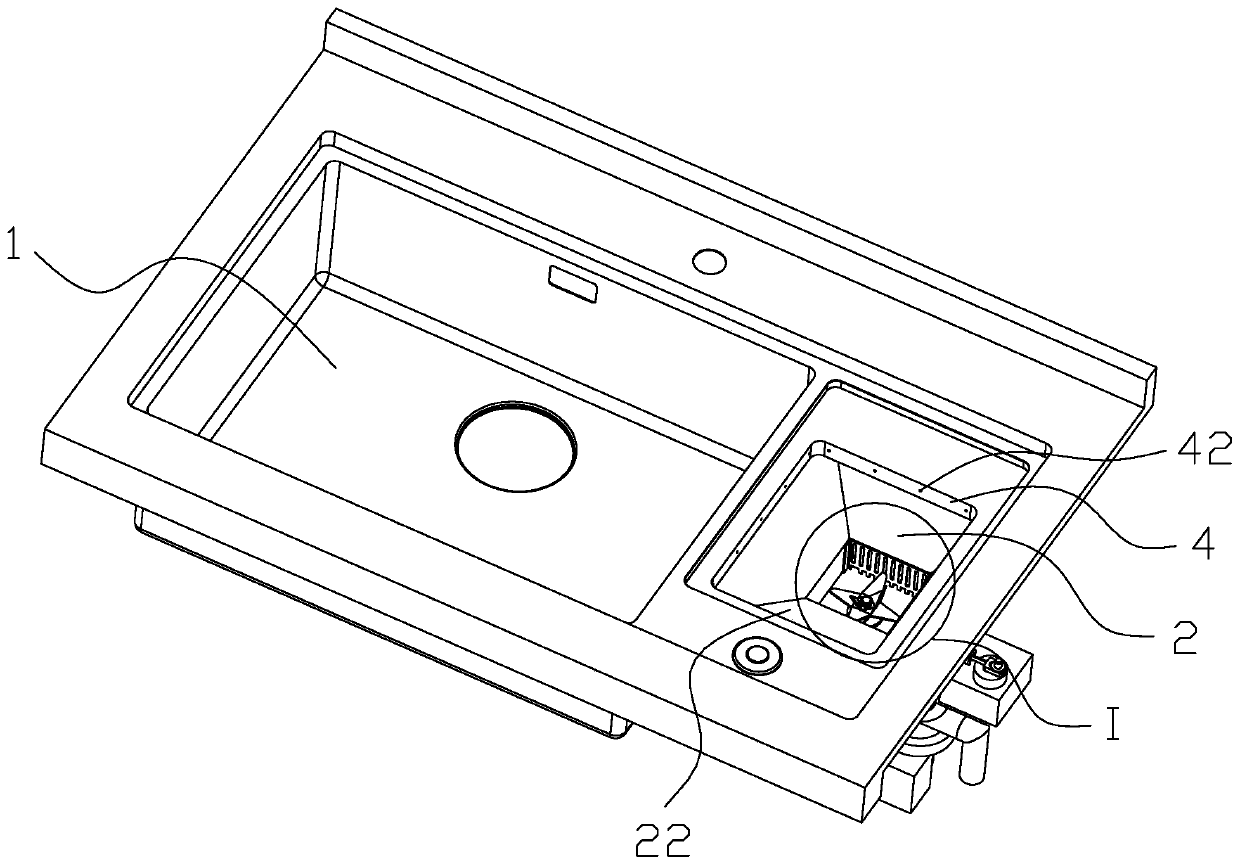

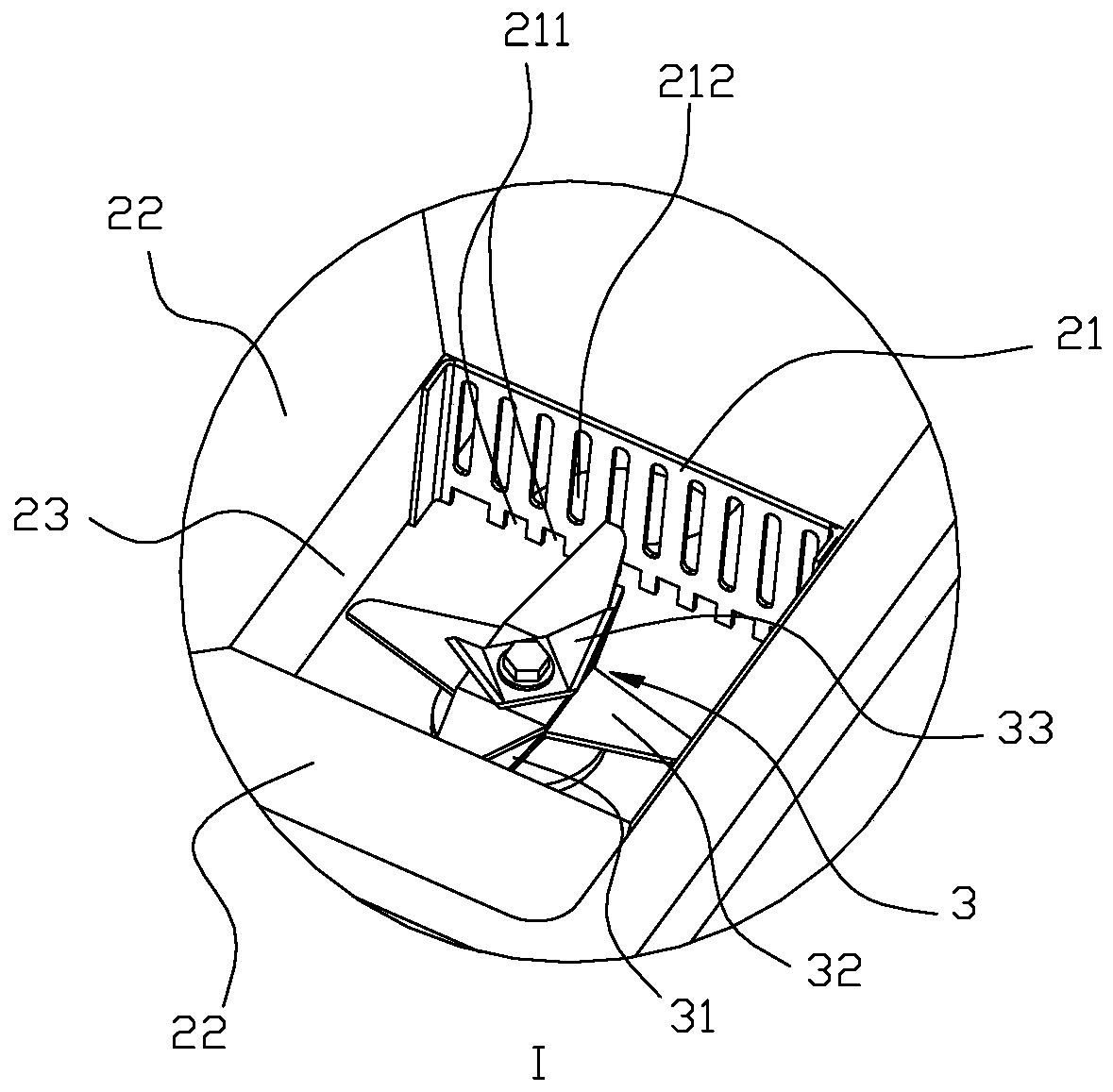

[0027] A sink garbage disposer of the present invention such as figure 1 , 2, 3, 4 shown, water tank 1, tank body 2, water inlet device, crushing knife and drainpipe 6; Crushing knife is arranged in the tank body, comprises blade 3 and motor 5, and blade 3 is connected with motor 5; Tank body and The water tank is integrally connected (or close to the connection); the path of the drain pipe 6 is provided with an electronically controlled drain valve 61, and the electrically controlled drain valve 61 is only opened during the process of draining water, which can be used according to the needs of continuous or intermittent treatment of garbage. It can be turned on or off during the crushing operation to realize more efficient crushing operations; a water level sensor 24 is arranged above the electric control drain valve, and the water level sensor 24 is connected to the central control circuit board; a partition is arranged between the crushing knife and the drain pipe. Plate 2...

Embodiment 2

[0033] The difference between the sink garbage disposer of Embodiment 2 and Embodiment 1 is shown in 5. The shroud 23' is made of a single-panel body curled into an arc, and the axis of the arc is collinear with the axis of the pulverizer. When the pulverizer rotates, The distance between the blade tip of the knife blade and the shroud 23' is always consistent, and the rebound strength of the garbage thrown centrifugally by the blade and the shroud is relatively small after collision, and the rebound strength is also relatively consistent, making the crushing process of the garbage relatively smooth. stable; the inner surface of the coaming plate 23' is also provided with a raised disturbance plate 231', the disturbance plate 231' can collide with the garbage with a larger particle size, and bounce the garbage to the shredder knife to prevent the garbage with a larger particle size from The inside of the crushing chamber is never touched and cut, thus remaining in the crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com