Floating type draught fan foundation

A wind turbine foundation, floating technology, applied in the installation/supporting configuration of wind turbines, wind power generation, floating buildings, etc., can solve the problems of not being suitable for use in sea areas below 50 meters, and achieve strong adaptability to water depth and reduce use Cost, the effect of reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

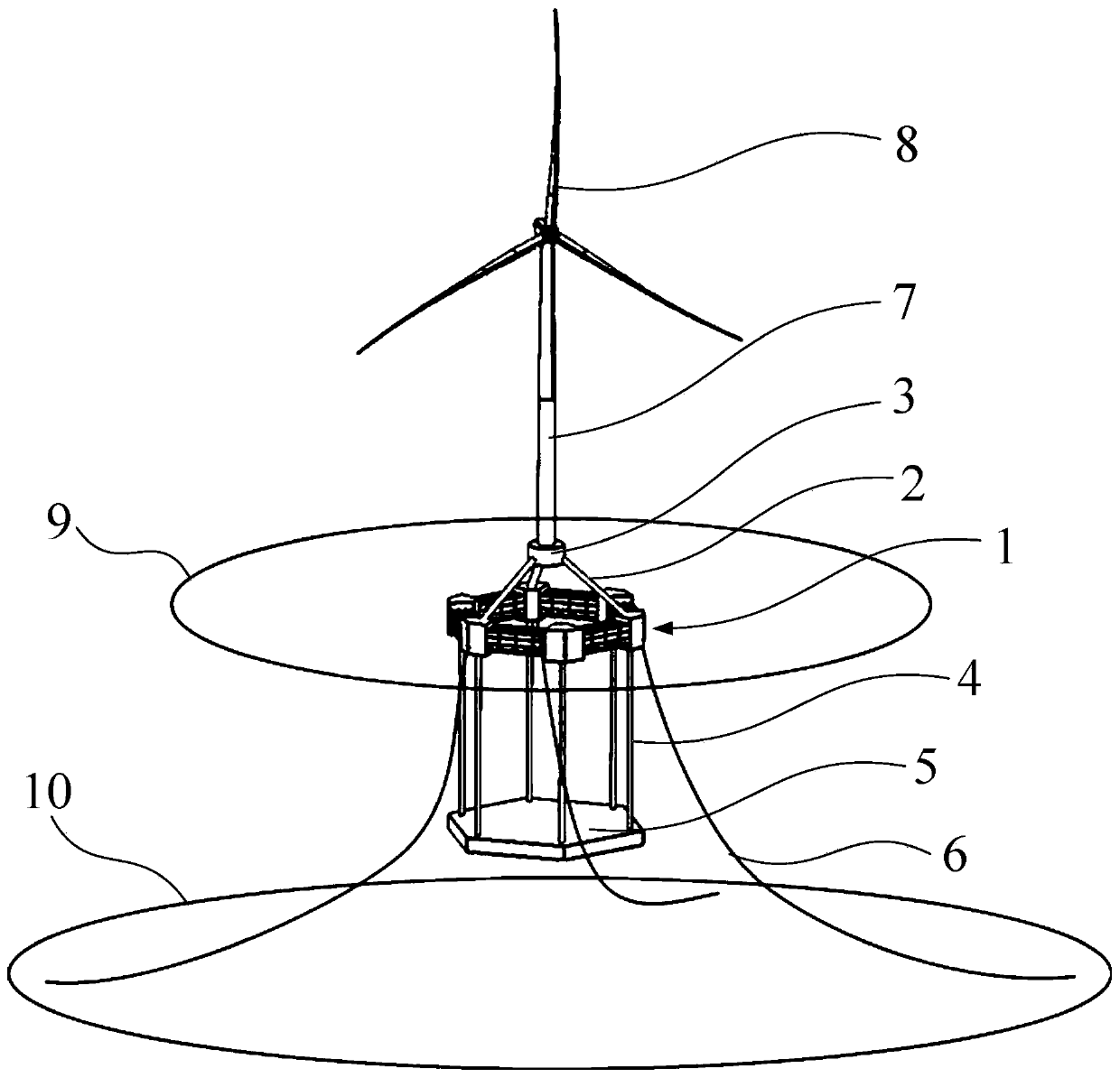

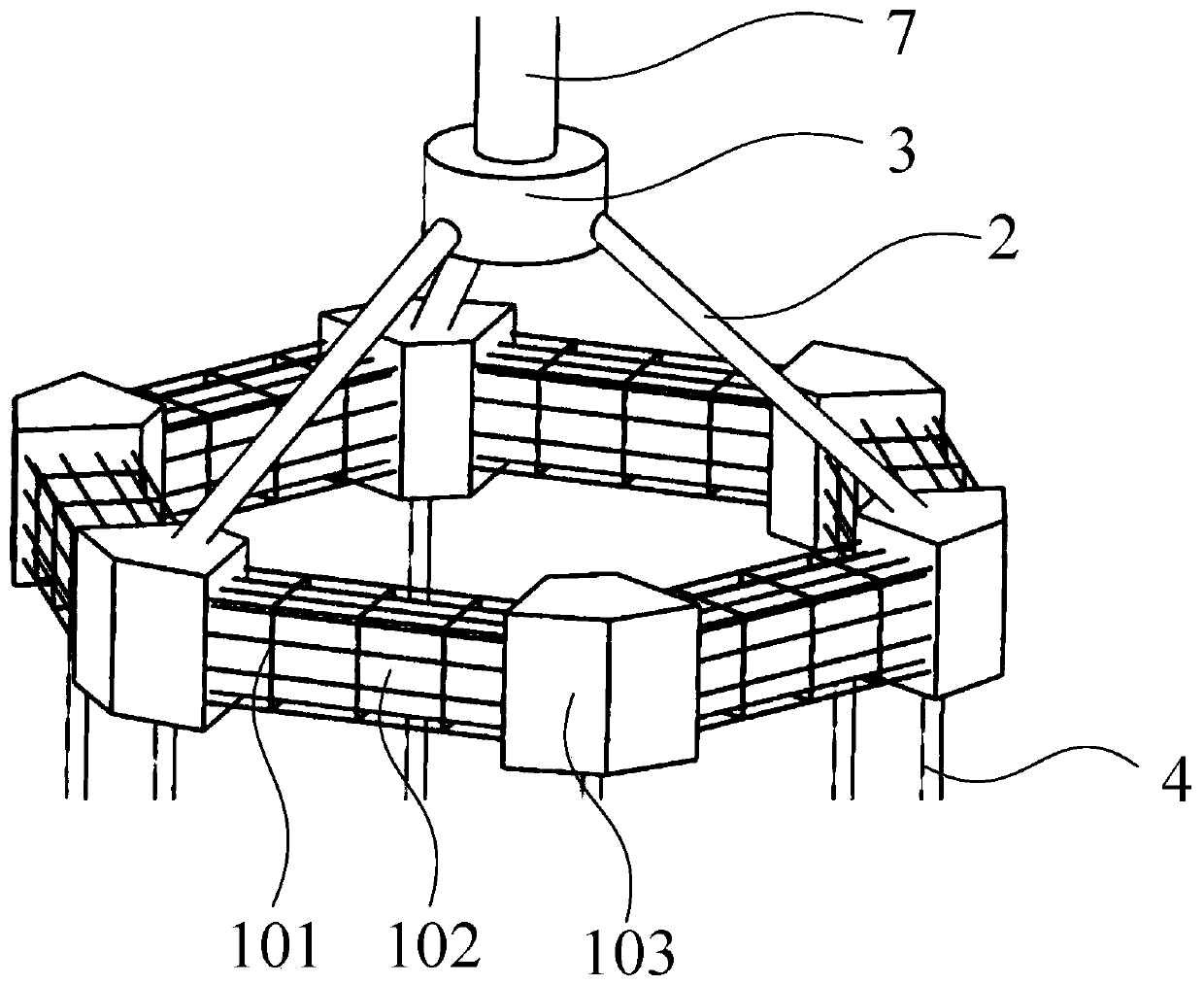

[0059] The overall structure of the floating wind turbine foundation includes tower installation platform 3, connecting body 103, rigid cage 101, floating block 102, rigid connector 4, ballast tank 5, anchor chain 6 and other structures, and wind turbine 8 and tower 7 together form an offshore floating wind turbine system, such as figure 1 shown. The specific implementation is as follows:

[0060] The upper section of the floating fan base transition structure tower installation platform 3 is a steel cylindrical structure with a diameter larger than the outer diameter of the tower 7, and is connected to the section of the tower 7 through a flange. The lower section of the transition structure is a steel cylindrical brace (rigid member 2), and the bottom end of the brace can be fixed to the structural connector 103 by means of anchor bolts, welding, etc.

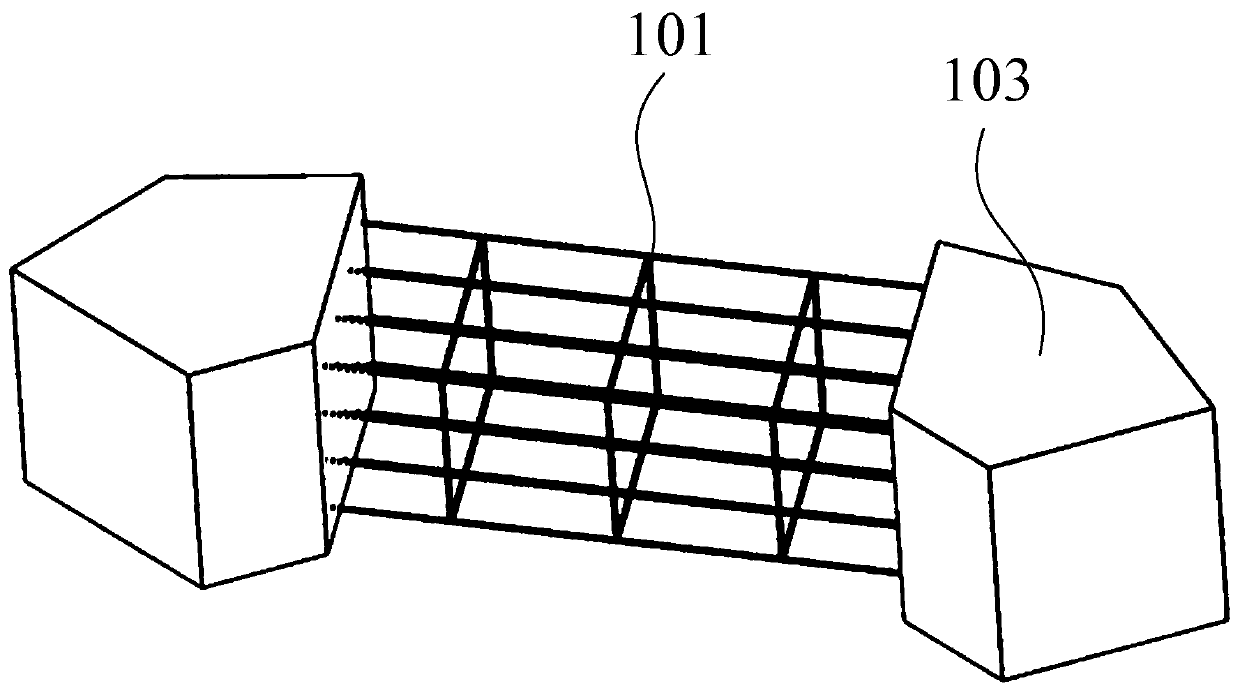

[0061] The structural connecting body 103 of the floating fan foundation is a steel column, its upper part is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com