Combined heat, power and cooling system and operation method based on liquefied natural gas gasification cold energy

A technology of liquefied natural gas and cogeneration of heat, power and cooling, which is applied in the field of combined heating and refrigeration systems, and can solve problems such as lack of efficient utilization of technology, waste, and difficulty in fully excavating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

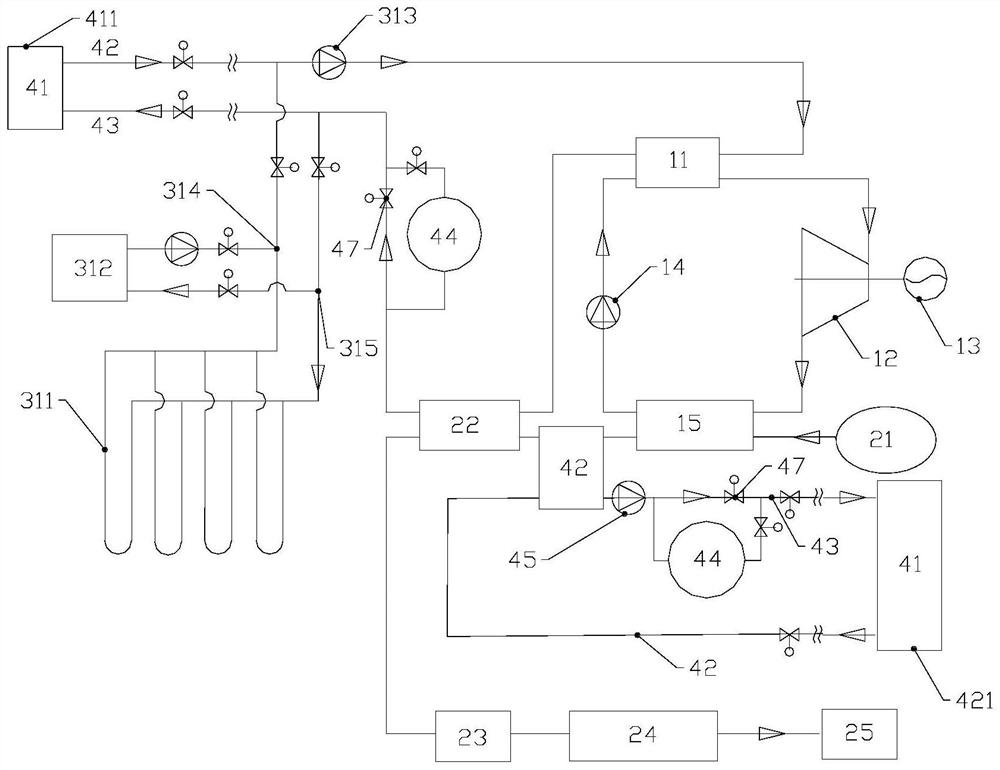

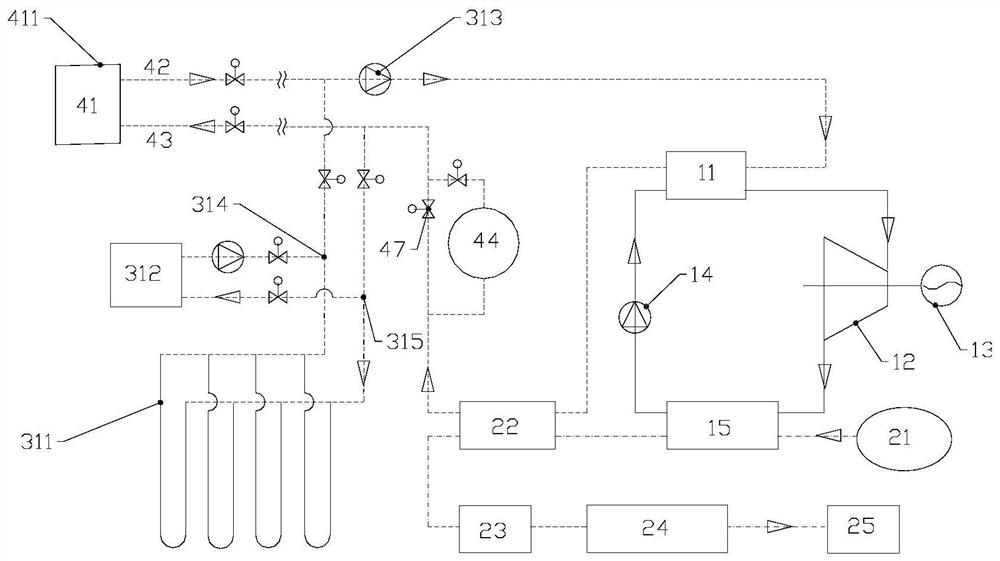

[0079] The system of embodiment 1 forms two different operation methods according to the actual needs of different regions, cold user 41, cold storage tank 44, air heating tower 312 and shallow buried pipe heat exchanger 311:

[0080] Such as figure 2 In the shown operation method 101, for hot summer and cold winter regions, the cold user 41, the air heating tower 312, and the buried pipe heat exchanger 311 are connected in parallel:

[0081] The refrigerant return line of the cooling user 41 is connected in parallel with the cooling water return line of the air heating tower and the return line branch of the buried pipe heat exchanger 311, and the water supply lines of the three are connected in parallel, and the refrigerant return line is connected with the low-temperature boiler 11 The refrigerant outlet on the cold side of the low-temperature boiler 11 is connected to the refrigerant outlet on the hot side of the user warmer 46, and the refrigerant inlet of the user warme...

Embodiment 2

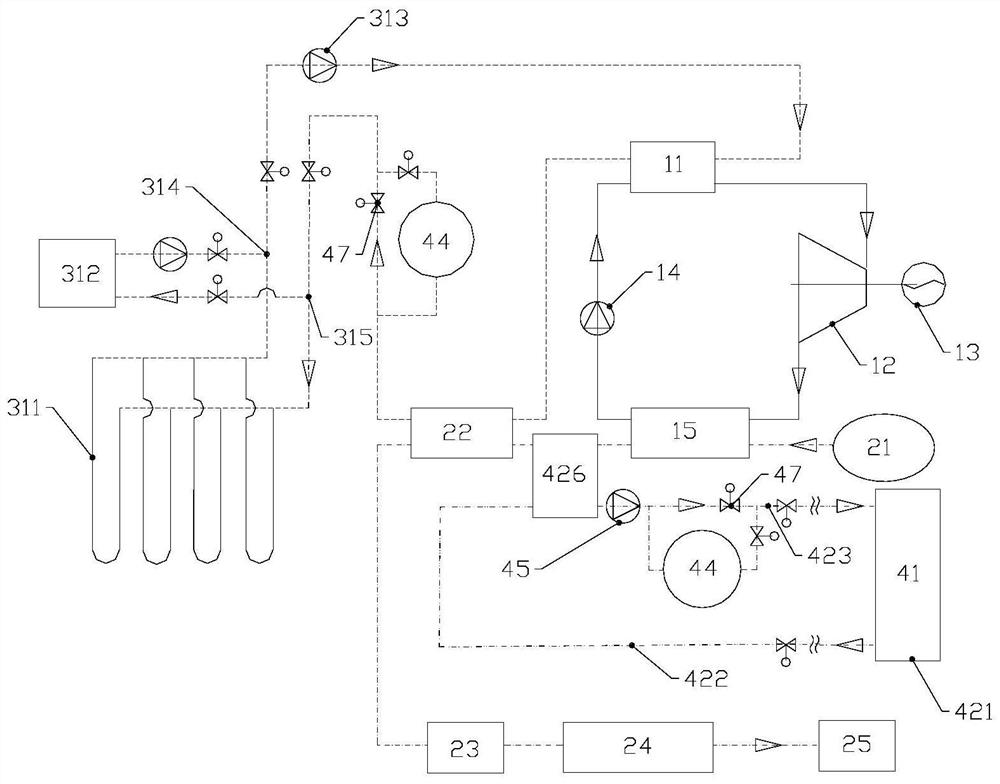

[0110] Embodiment 2 If only judged according to cooling and heating load demands, three different operation modes are adopted according to demands:

[0111] Such as Figure 9 In the operation mode 201 shown, in the non-heating and non-cooling period, the heat medium of the low-grade heat source 321 first enters the low-temperature boiler 11 of the low-temperature thermal power generation sub-system to release heat and cool down, and then enters the main temperature booster 22 to further heat the low-temperature gasified natural gas While continuing to release heat, the cooled heat medium returns to the low-grade heat source 321 through the heat medium pipeline to be heated and raised, so that the cycle continues; pipeline;

[0112] For the liquefied natural gas gasification subsystem, the LNG vaporizer 15 is first heated by the low-temperature steam of the power generation sub-system to become a low-temperature gaseous natural gas, and then enters the main temperature booster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com