A heat pump driven internal cooling solution dehumidification fresh air unit

A solution dehumidification, heat pump driven technology, applied in space heating and ventilation, space heating and ventilation details, household heating and other directions, can solve the problem of lack of heat pump driven solution dehumidification device, solution concentration reduction, etc., to meet the improvement demand Inconsistencies, full utilization, effects of improving energy efficiency levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

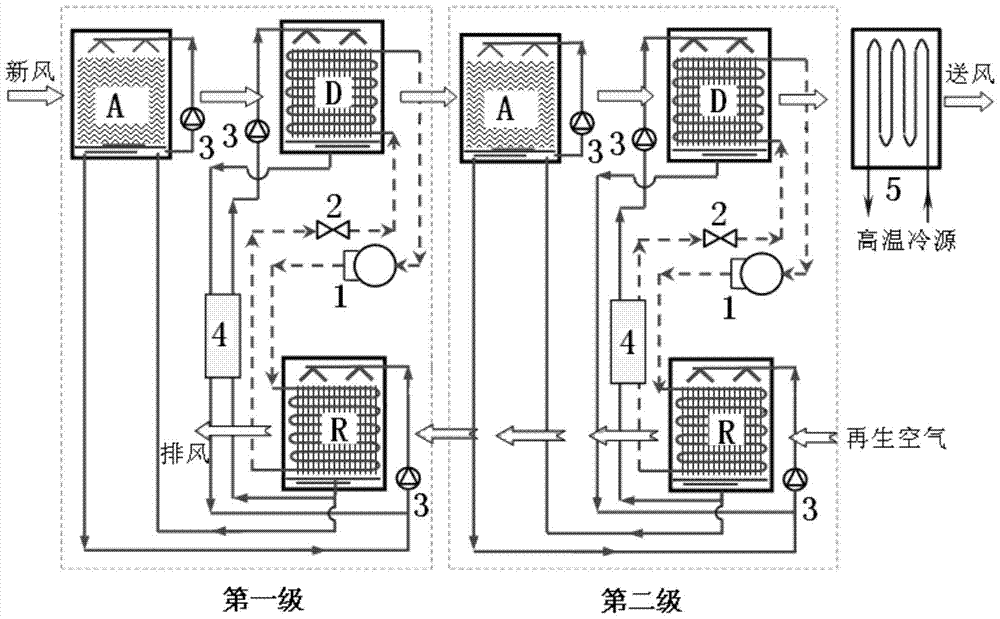

[0017] like figure 1 As shown, the fresh air unit of this embodiment includes fresh air processing units arranged in multiple stages, and each fresh air processing unit includes an internal cooling type solution dehumidifier D, an internal heating type solution regenerator R, and an auxiliary adiabatic type solution dehumidifier A device A, a compressor 1 and an expansion valve 2, wherein, an evaporator is built in the internal cooling type solution dehumidifier D, a condenser is built in the internal heating type solution regenerator R, and the compressor 1, the internal heating type solution regenerator R The condenser in D, the expansion valve 2 and the evaporator in the internal cooling solution dehumidifier D are connected in sequence to form a heat pump cycle. The auxiliary adiabatic solution dehumidifier A is connected with a solution circulation pump 3 to form a solution circulation loop in the dehumidifier; the internal heating solution regenerator R passes through a ...

Embodiment 2

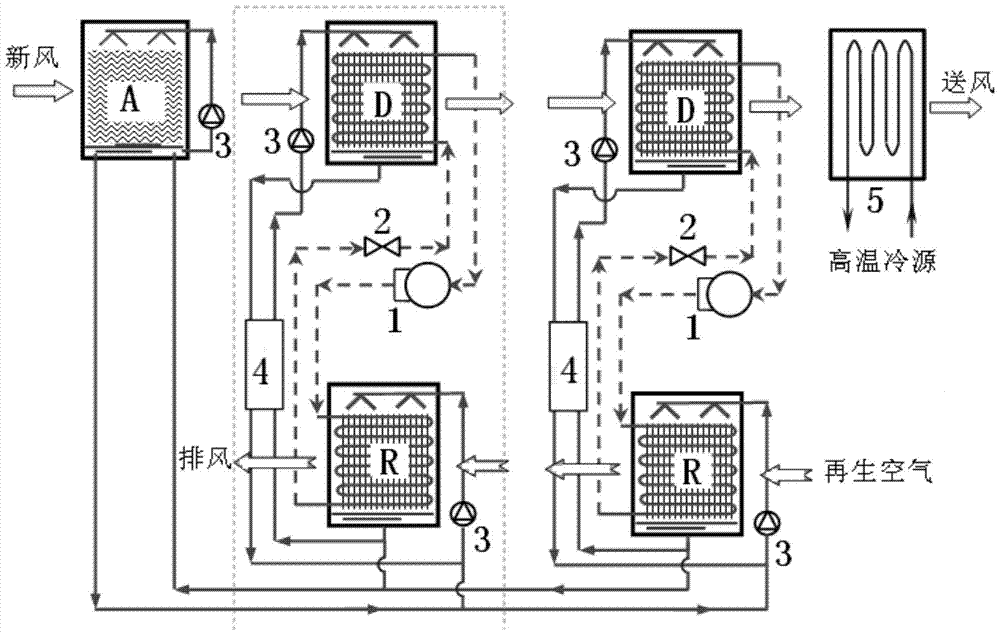

[0028] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that no auxiliary adiabatic solution dehumidifier A is installed in the fresh air treatment units at all levels, and only one auxiliary adiabatic solution dehumidifier is installed in the whole fresh air treatment unit. A device A, which is set in front of the internal cooling solution dehumidifier D of the first-stage fresh air processing unit, and the auxiliary adiabatic solution dehumidifier A is connected with a solution circulation pump 5 to form a solution circulation loop in the dehumidifier to assist the adiabatic solution dehumidification The device A is connected with the internal heating solution regenerator R of the fresh air treatment units at all levels to form a solution circulation loop.

[0029] The working principle of the fresh air treatment unit in this embodiment (the fresh air treatment unit including two-stage fresh air treatment unit I is used as an example to ill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com