Heat recovery type multi-stage solution dehumidifying fresh air handling unit

A solution dehumidification, fresh air unit technology, applied in heat recovery systems, space heating and ventilation, space heating and ventilation details, etc. The effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

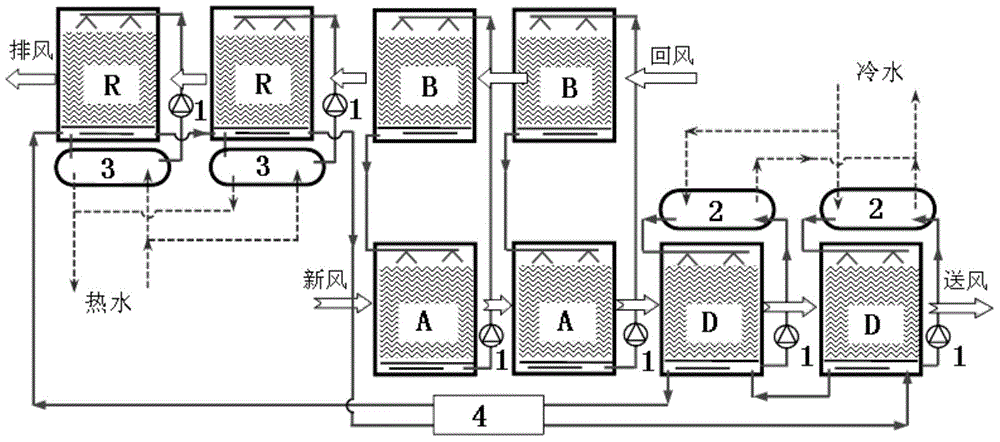

[0015] Such as figure 1 As shown, the fresh air unit in this embodiment includes a fresh air processing channel and a return air processing channel, wherein the fresh air processing channel is arranged in the lower layer of the return air processing channel.

[0016] The fresh air treatment channel includes a solution-air direct contact module A with two levels (take two levels as an example, not limited to two levels), and two levels (take two levels as an example, not limited to two levels) are set behind the solution-air direct contact module A. limited to two stages) solution dehumidifier D. The return air treatment channel includes a solution-air direct contact module B set in two stages (taking two stages as an example, not limited to two stages), and two stages are arranged in front of the solution-air direct contact module B (taking two stages as an example, Not limited to two stages) solution regenerator R. Each solution-air direct contact module A is connected to t...

Embodiment 2

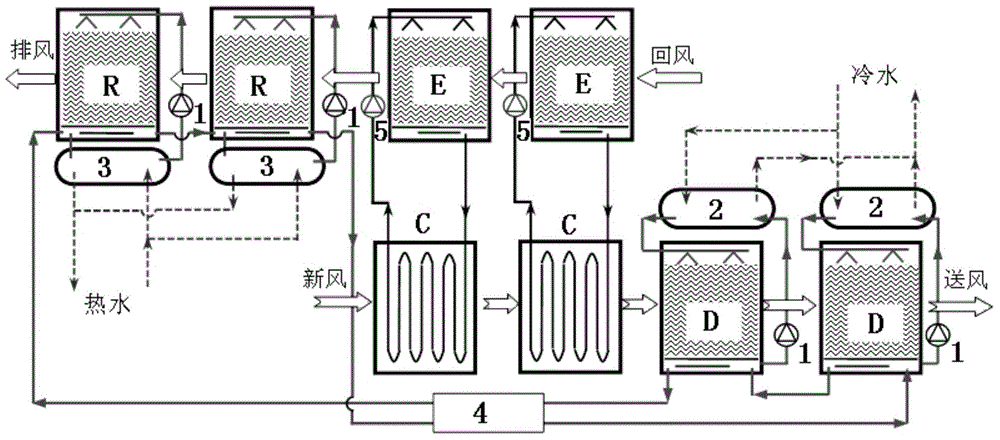

[0026] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment replaces the two-stage solution- The air directly contacts the module A, and at the same time, the two-stage solution-air direct contact module B located in the return air treatment channel of the first embodiment is replaced by a two-stage (two-stage as an example, not limited to two) direct evaporative cooler E. Moreover, each surface cooler C is connected to the direct evaporative cooler E through a water pump 5 to form a water circulation loop.

[0027] In this embodiment, in summer, the heat exchange end of the solution-water heat exchanger 2 can be connected with the cold water pipeline, so as to take away the heat in the heat mass exchange process between the solution and the air, and enhance the dehumidification capacity of the solution; and in winter , then the heat exchange end of the solution-water heat exchanger 2 can be connected to the hot water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com