Simulation environment hydraulic pressure stabilizing device suitable for dynamic loading and application method thereof

A technology of simulating environment and dynamic loading, applied in the field of testing, it can solve problems such as poor applicability, large volume, and liquid pressure changes, and achieve the effect of simple assembly and disassembly, flexible application and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

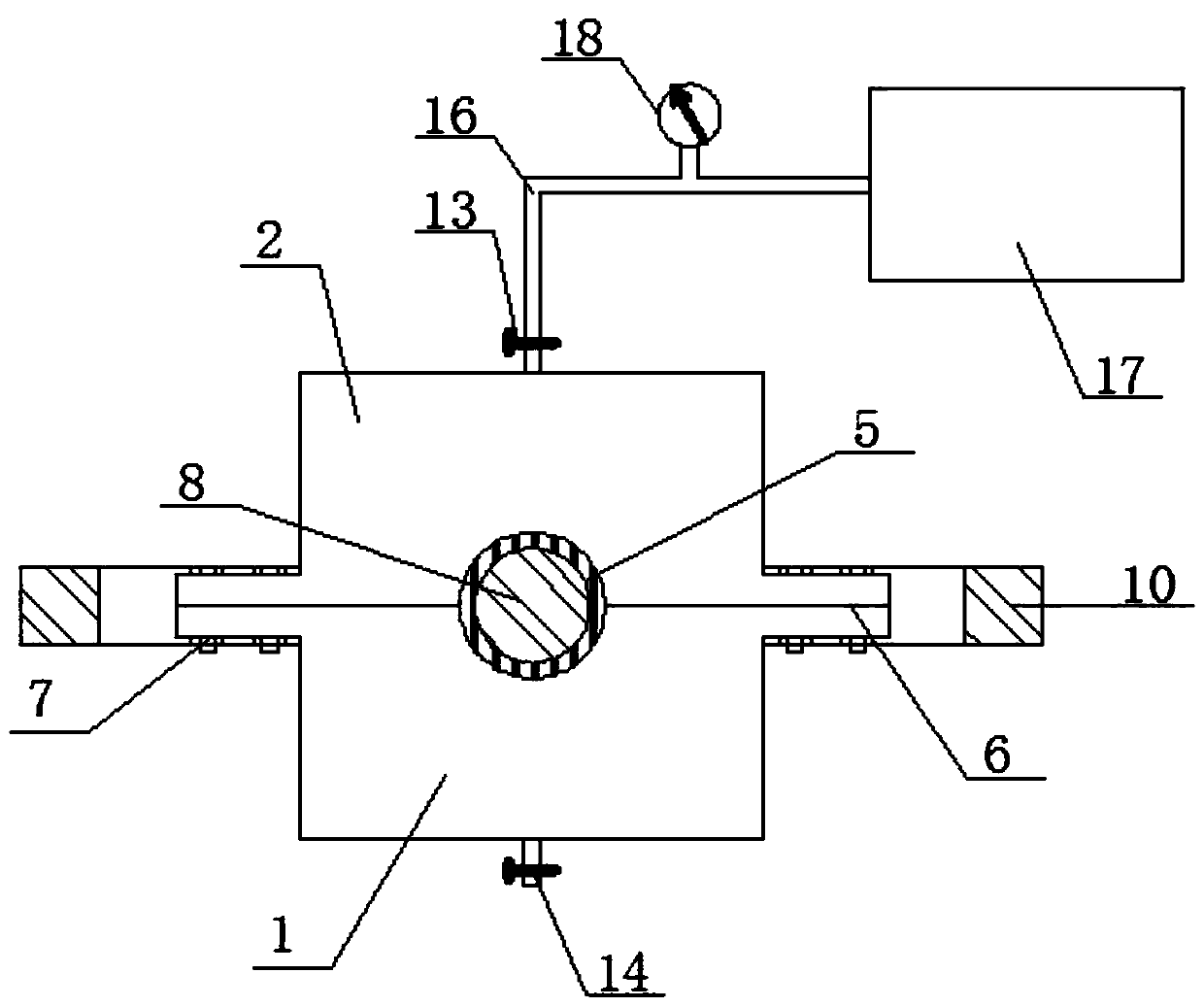

Method used

Image

Examples

Embodiment 1

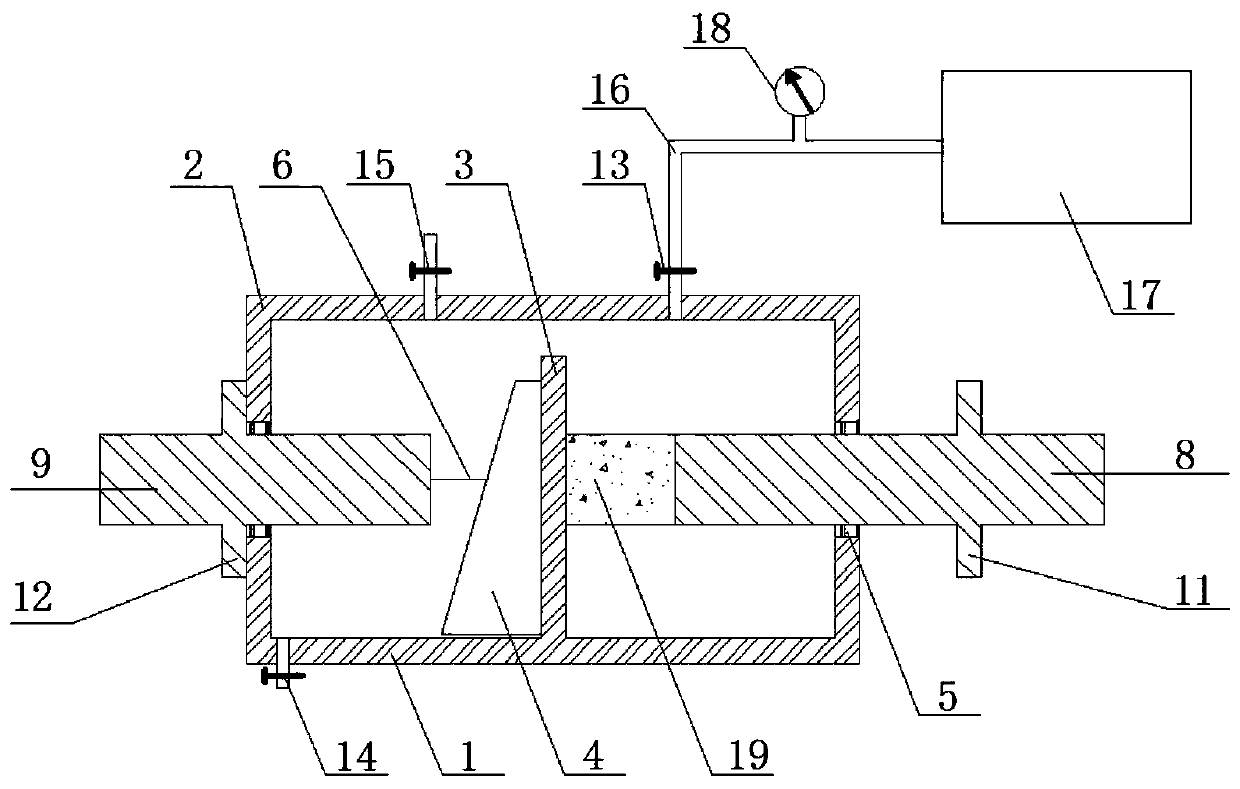

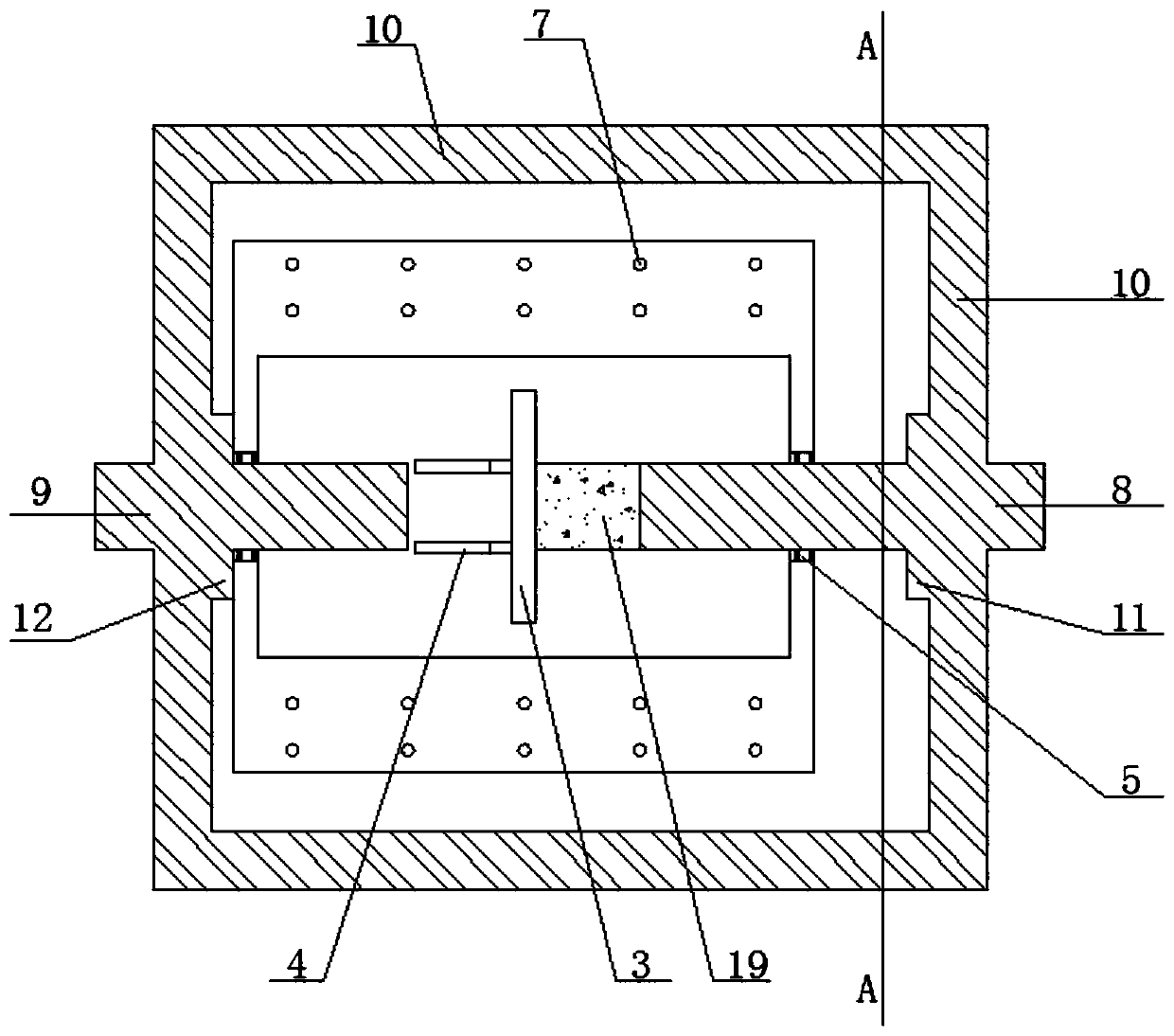

[0046] A simulated environment hydraulic pressure stabilizing device and application method suitable for dynamic loading, using a universal testing machine as a loading device, comprising the following steps:

[0047] Step 1, remove the upper cylinder body 2, place the cubic test piece 19 between the loading rod 8 and the bearing surface 3, and use the loading rod 8 to compress the test piece 19;

[0048] Step 2, close the upper cylinder body 2 and the lower cylinder body 1, place a rubber cushion layer 6 on the contact surface between the upper cylinder body 2 and the lower cylinder body 1, and place the upper cylinder body 2, the lower cylinder body 1 and the loading rod 8, A seal 5 is installed at the contact surface of the pressure stabilizing rod 9, and the upper cylinder body 2 and the lower cylinder body 1 are tightened by bolts 7;

[0049]Step 3, place the cylinder vertically so that the loading end of the universal testing machine is in contact with the outer end of t...

Embodiment 2

[0054] A simulated environment hydraulic pressure stabilizing device and application method suitable for dynamic loading, using SHPB as a loading device, comprising the following steps:

[0055] Step 1, remove the upper cylinder body 2, place the cylindrical test piece 19 between the loading rod 8 and the bearing surface 3, and use the loading rod 8 to compress the sample to be tested;

[0056] Step 2, close the upper cylinder body 2 and the lower cylinder body 1, place a rubber cushion layer 6 on the contact surface between the upper cylinder body 2 and the lower cylinder body 1, and place the upper cylinder body 2, the lower cylinder body 1 and the loading rod 8, A seal 5 is installed at the contact surface of the pressure stabilizing rod 9, and the upper cylinder body 2 and the lower cylinder body 1 are tightened by bolts 7;

[0057] Step 3, place the cylinder horizontally so that the end of the incident rod of the SHPB is in contact with the outer end of the loading rod 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com