Aircraft reliability evaluation method based on assembly outline and fault list

A trouble ticket and reliability technology, applied in data processing applications, instruments, resources, etc., can solve problems such as complicated procedures, complex internal structures, and large volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

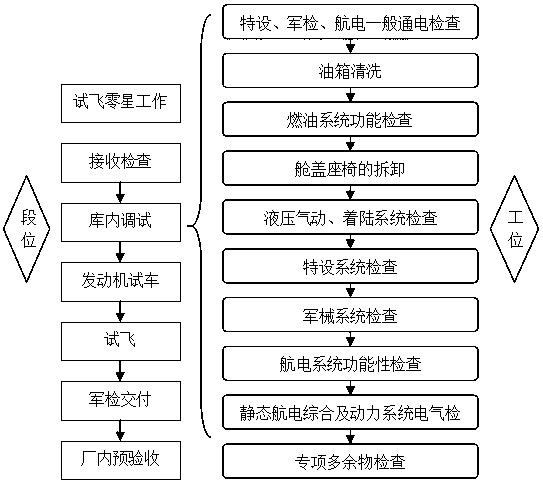

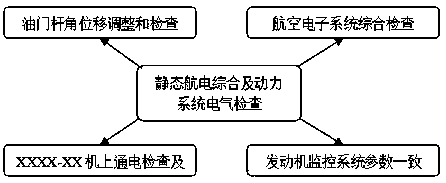

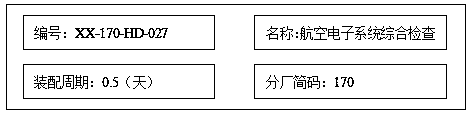

[0086] The aircraft reliability evaluation method based on the assembly program and fault list proposed by the present invention calculates the mean time between failures (MTBF) and the mean flight time between failures according to the actual situation of the aircraft from entering the flight test station to the delivery period and the assembly program issued by the process. The actual reliability index observations of the four items of MFHBF, mission success probability MCSP, and mission time between fatal failures MTBCF are compared with the minimum acceptable value of the design and finalized to obtain the reliability evaluation results, so as to carry out aircraft evaluation. Reliability assessment.

[0087] This embodiment will calculate the mean time between failures MTBF, the mean time between failures and flight hours MFHBF, the success probability of completing the task MCSP, and the task time MTBCF four indicators between fatal failures when the military aircraft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com