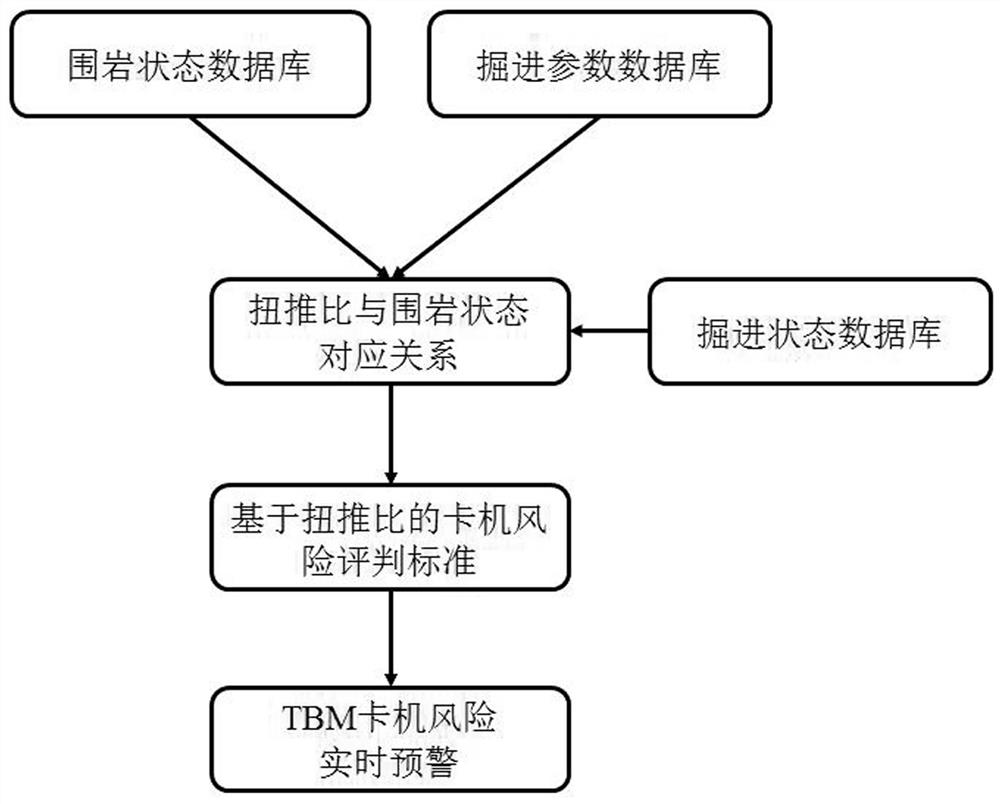

A risk warning method for TBM jamming in broken formations based on torsion-push ratio

A risk warning and jamming technology, which is applied in the fields of earthwork drilling, instrumentation, data processing, etc., can solve the problems of delay in construction period, decreased driving speed, poor adaptability, etc., so as to reduce the impact, improve the construction efficiency, and reduce the risk of being jammed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A method for early warning of TBM jamming risk in broken formations based on torsion-push ratio, comprising the following steps:

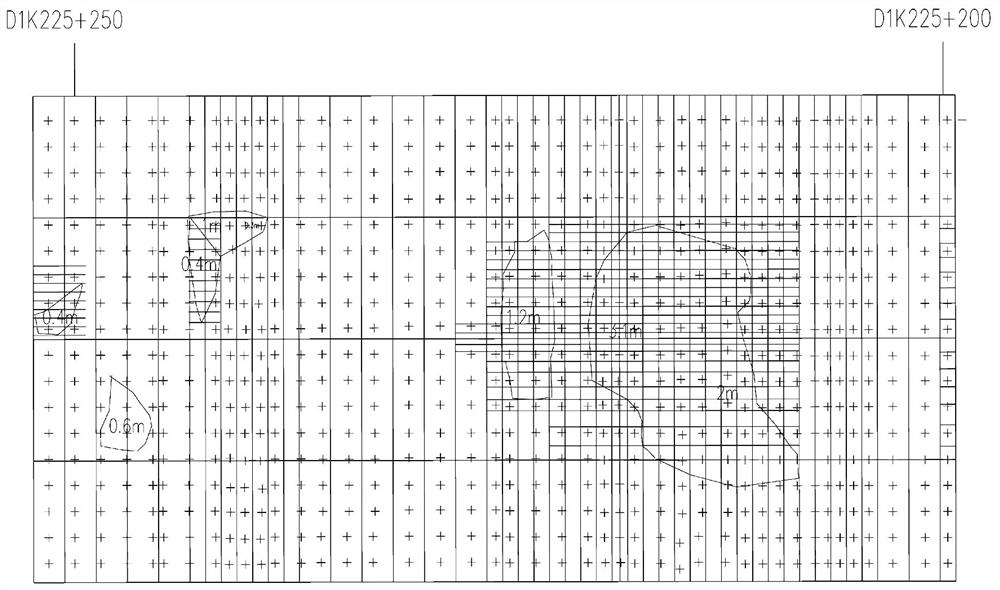

[0031] S1, collect surrounding rock state data through the geological sketch of the surrounding rock exposed shield;

[0032] The collected surrounding rock state data includes the excavation mileage, the position of the surrounding rock collapse cavity on the tunnel section, the range of the collapse cavity, and the depth of the collapse cavity, as well as the type and spacing of the steel arch frame used to support the collapse cavity, and the type of steel bar row used. and spacing, the length and spacing of bolts used; the surrounding rock state diagram of a certain section of a tunnel is as follows figure 2 shown.

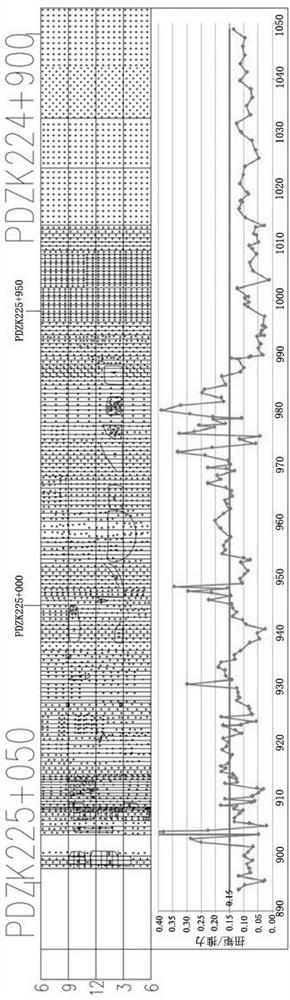

[0033] S2, obtaining TBM excavation parameter data through the TBM data acquisition system;

[0034] The acquired excavation parameter data includes but not limited to excavation mileage, thrust, torque, adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com