Circuit breaker moving contact with arc contact

A technology of arcing contacts and moving contacts, which is applied in the field of moving contact structures, can solve problems such as difficulty in improving short-circuit breaking capacity of circuit breakers, arc burning and erosion, and affecting post-test verification, etc., and achieves simple structure, improved breaking capacity, Improvement of electrical life and mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

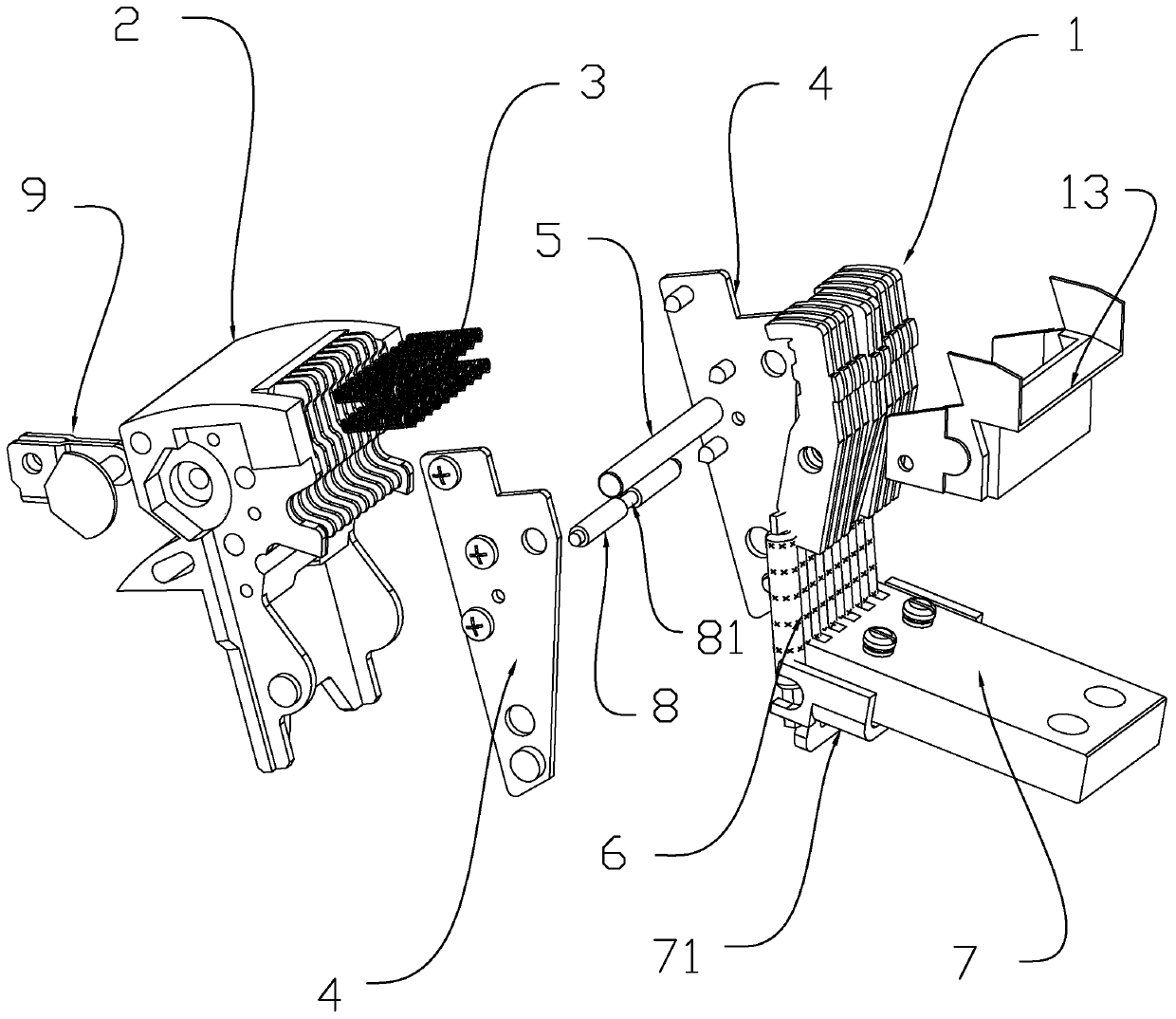

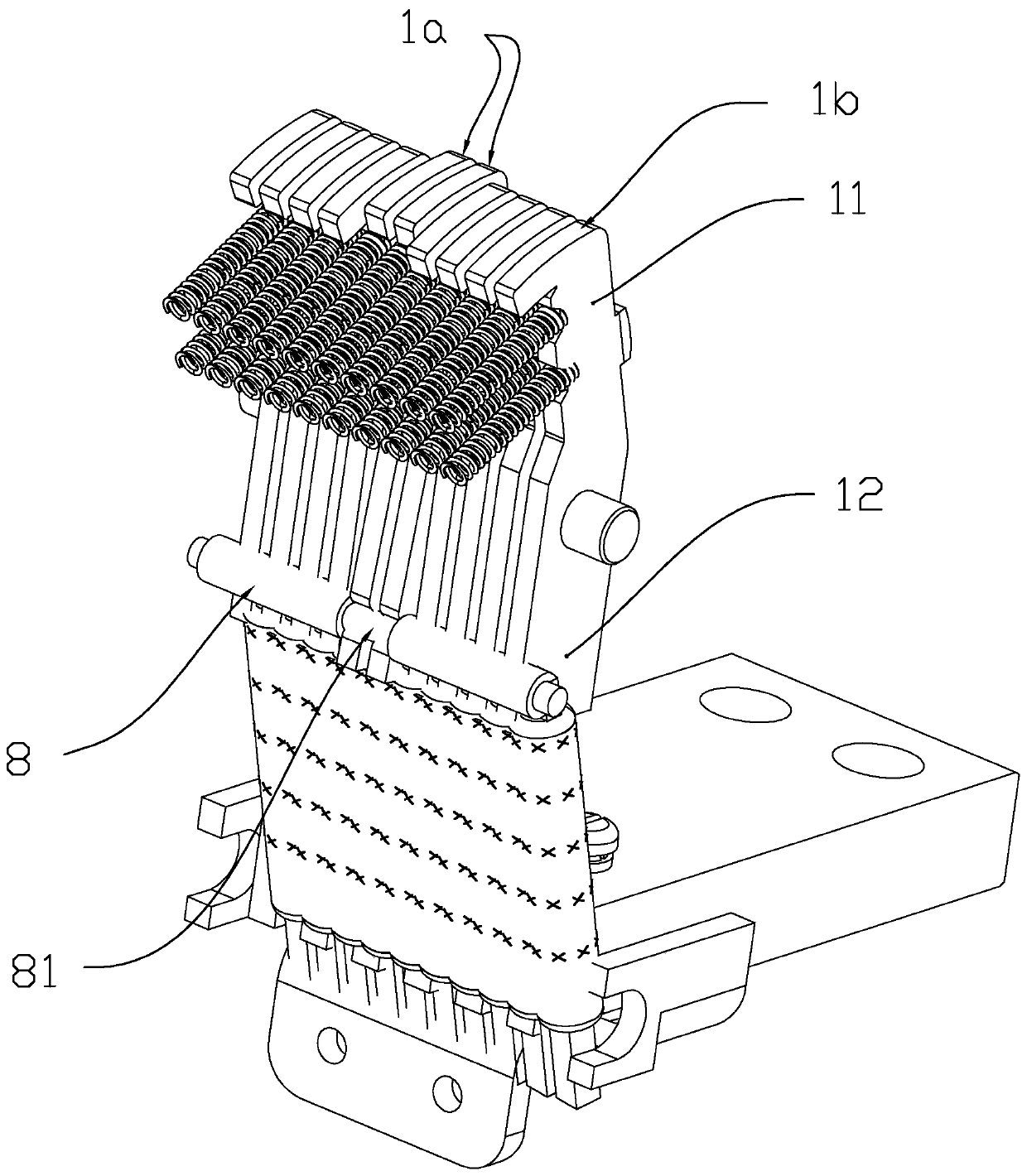

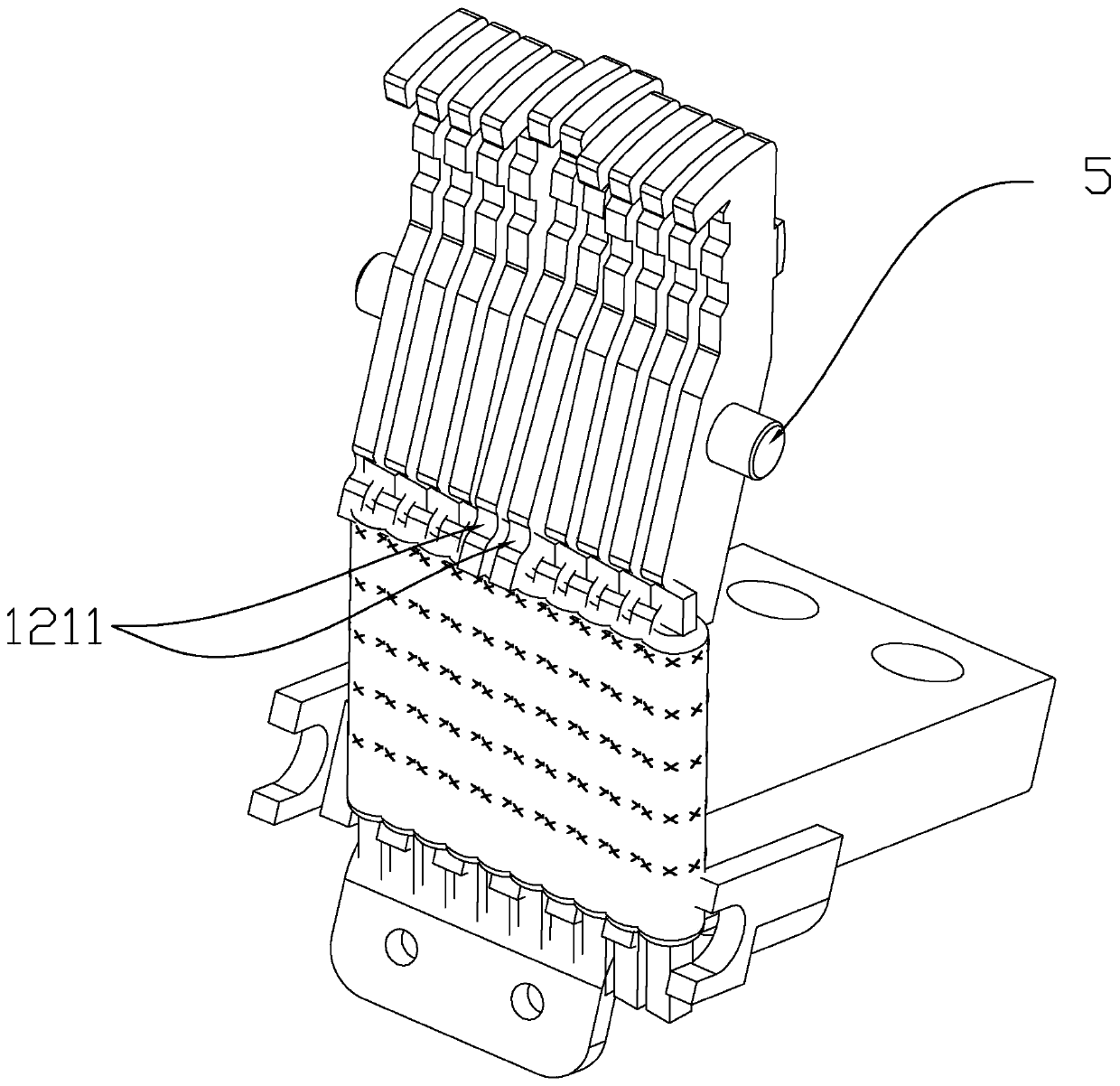

[0025] Specific embodiments of the present invention such as Figure 1-5 As shown, a moving contact of a circuit breaker with an arcing contact includes a contact system 1, a contact support 2, a contact spring 3, a contact side plate 4, a connecting shaft 5, a soft connection 6 and a moving contact female row 7, the contact spring 3 is located between the contact system 1 and the contact support 2, the contact system 1 includes several contact pieces, and the contact pieces are all sleeved on the connecting shaft 5, the contact The ends of the head piece located on both sides of the connecting shaft 5 are the abutting end 11 abutting against the contact spring 3 and the connecting end 12 connected with the soft connection 6 respectively, and the side of the connecting end 12 is provided with a connecting end 12 The abutting limit rod 8, the middle part of the limit rod 8 has a cavity 81, the bottom surface of the cavity 81 is lower than the surface of other positions of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com