System and process for the production of durene by injection cycle methanol aromatics methylation reaction

A technology of durene and methylation, applied in catalysts, organic chemistry, hydrocarbons, etc., can solve the problems of high price and unsuitability for industrialized large-scale production, and achieve low raw material cost, easy procurement, and inhibition of alkylation The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

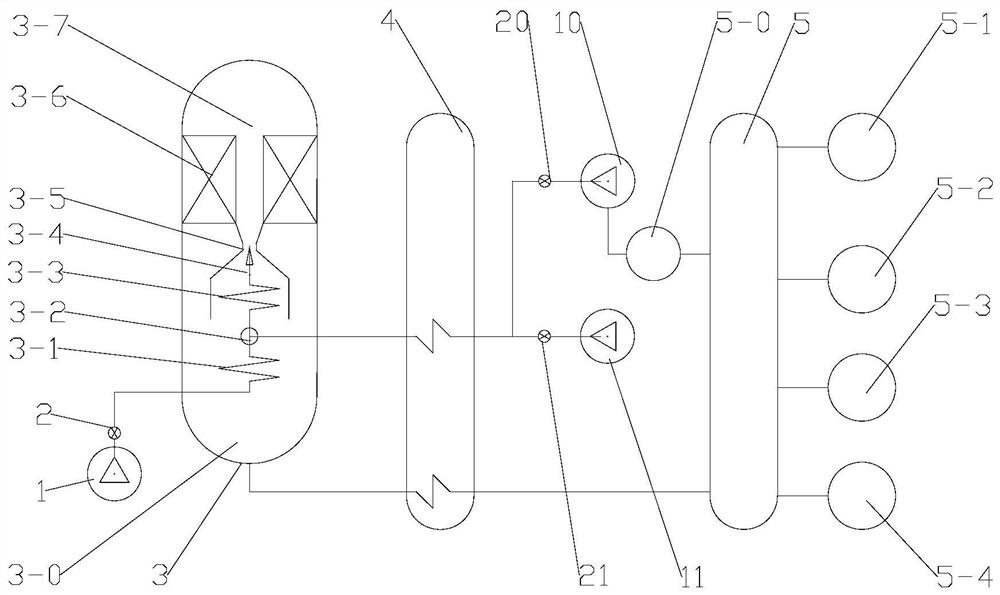

[0060] A system for the production of durene by injection cycle methanol aromatics methylation, such as figure 1 As shown, it includes a methanol pump 1 , a reactor 3 , a heat exchange system 4 and a separation and refining system 5 .

[0061] An outlet product heat exchanger 3-1, a mixer 3-2, an overheating heat exchanger 3-3, a nozzle 3-4, an ejector 3-5, and a catalyst bed 3-6 are installed in the reactor. The reactor 3 is divided into a product chamber 3-0 and an inlet chamber 3-7 by a catalyst bed 3-6, and the catalyst bed 3-6 adopts an axial flow catalyst bed. A heating device is arranged inside the catalyst bed 3-6. The catalyst bed layer 3-6 is provided with an inlet channel, and the inlet channel communicates with the product chamber 3-0 and the inlet chamber 3-7. A product heat exchanger 3-1, a mixer 3-2, a superheater heat exchanger 3-3, a nozzle 3-4, and an ejector 3-5 are arranged in the product chamber 3-0. The outlet of the ejector 3-5 is connected to the inl...

Embodiment 2

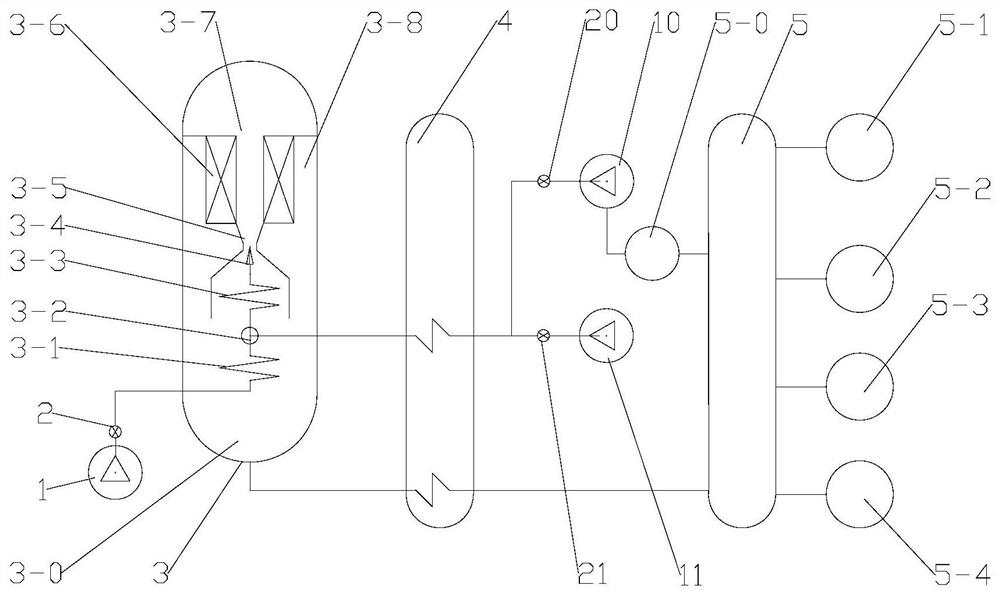

[0066] A system for the production of durene by injection cycle methanol aromatics methylation, such as figure 2 As shown, it is the same as in Example 1, except that the catalyst bed adopts a radial flow catalyst bed, and outlet channels 3-8 are arranged between the catalyst bed and the reactor wall.

Embodiment 3

[0068] Adopt the system of embodiment 1, the raw material is the technique that the injection circulation methylation reaction of methyl alcohol and toluene produces durene as follows:

[0069] The methanol raw material from the raw material methanol pump 1 and the methanol feed valve 2, at a temperature of 25°C and a pressure of 2.0 MPa, passes through the reactor 3 and enters the outlet product heat exchanger 3-1 in the product chamber 3-0, and is transferred from the catalyst bed The reaction product coming out of the outlet is heated and evaporated to about 200°C, and part of the product is cooled to about 280°C at the same time. Part of the high boiling point component in the product is condensed and sinks, and then mixed with part of the gaseous product and discharged from the reactor. The raw material methanol vapor passes through the mixer 3 -2 is mixed with raw aromatics circulating aromatics confluence gas to form a mixed gas. In the mixed gas, the molar ratio of raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com