Bending forming die for metal plate industry control cabinet

An industrial control and bending forming technology, applied in the field of mechanical processing, can solve the problems of springback, large error, inability to combine extrusion and reciprocating extrusion, etc., and achieve the effect of convenient blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

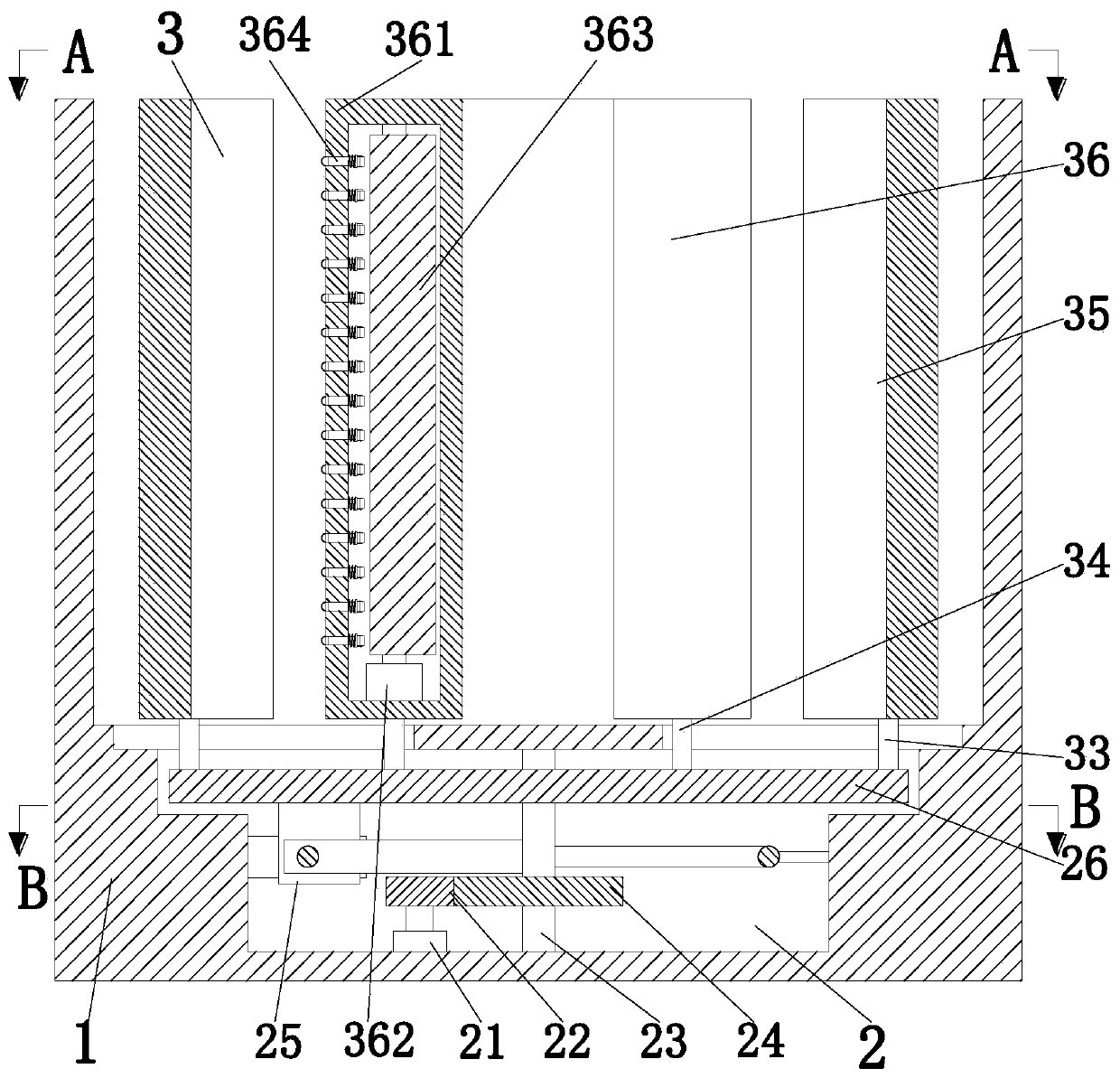

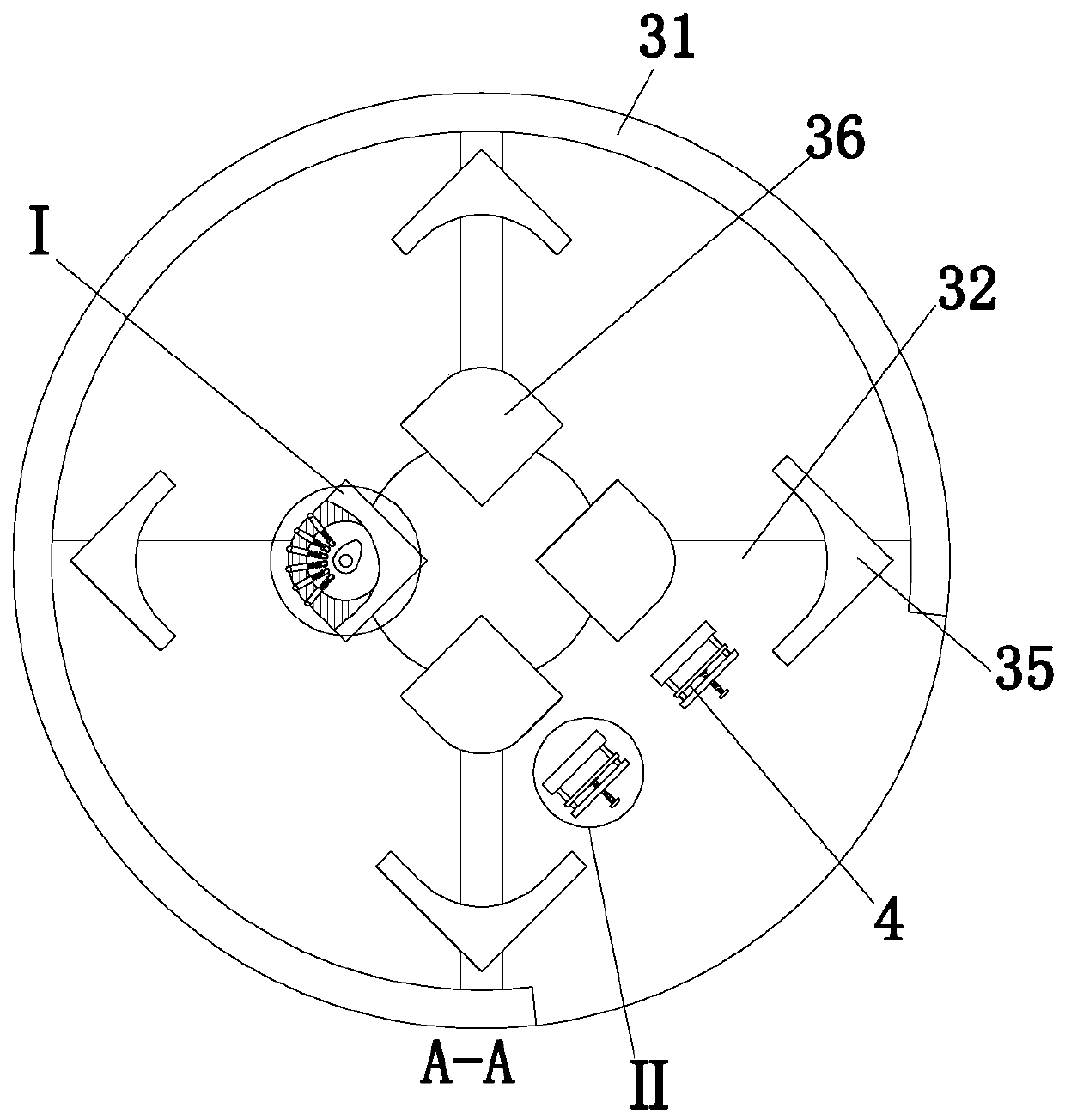

[0027] Such as Figure 1 to Figure 5 As shown, a sheet metal industrial control cabinet bending forming mold includes a base 1, a driving unit 2, a shaping unit 3 and a fixing unit 4. The base 1 is provided with a driving cavity inside, and a driving unit is arranged in the driving cavity 2. A shaping unit 3 is installed on the upper end of the base 1, and a fixing unit 4 is installed on the upper end of the base 1; the fixing unit 4 fixes the plate, and the driving unit 2 drives the shaping unit 3 to simultaneously shape and maintain pressure on the inner and outer sides of the plate.

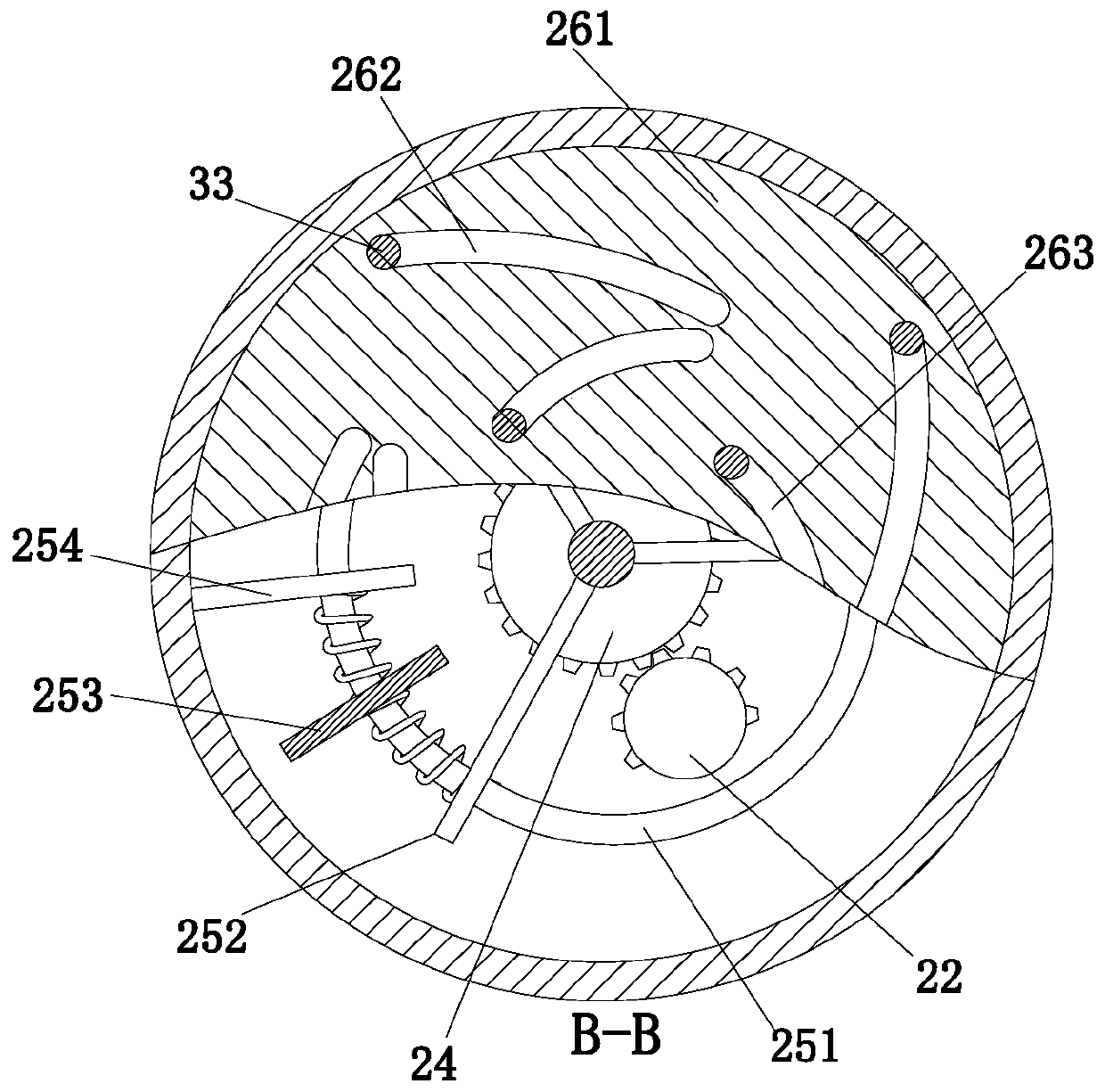

[0028] Described driving unit 2 comprises driving motor 21, half gear 22, rotating shaft 23, driving gear 24, pushing mechanism 25 and groove plate 26, and driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com