Overhaul device of steam turbine of thermal power plant

A technology for overhauling devices and steam turbines, applied to workbenches, manufacturing tools, etc., can solve problems such as slow overhaul progress, easy fatigue, and high energy consumption, and achieve the effects of avoiding the concentration of support forces, improving the scope of application, and dispersing support forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

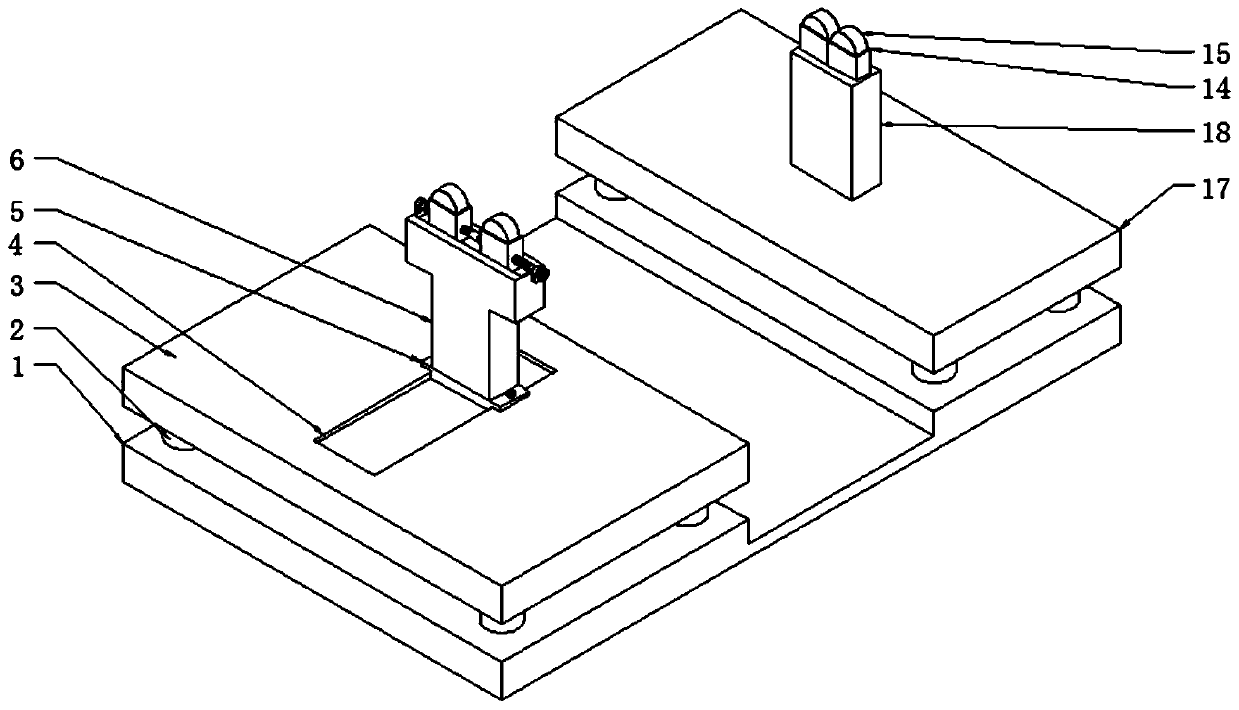

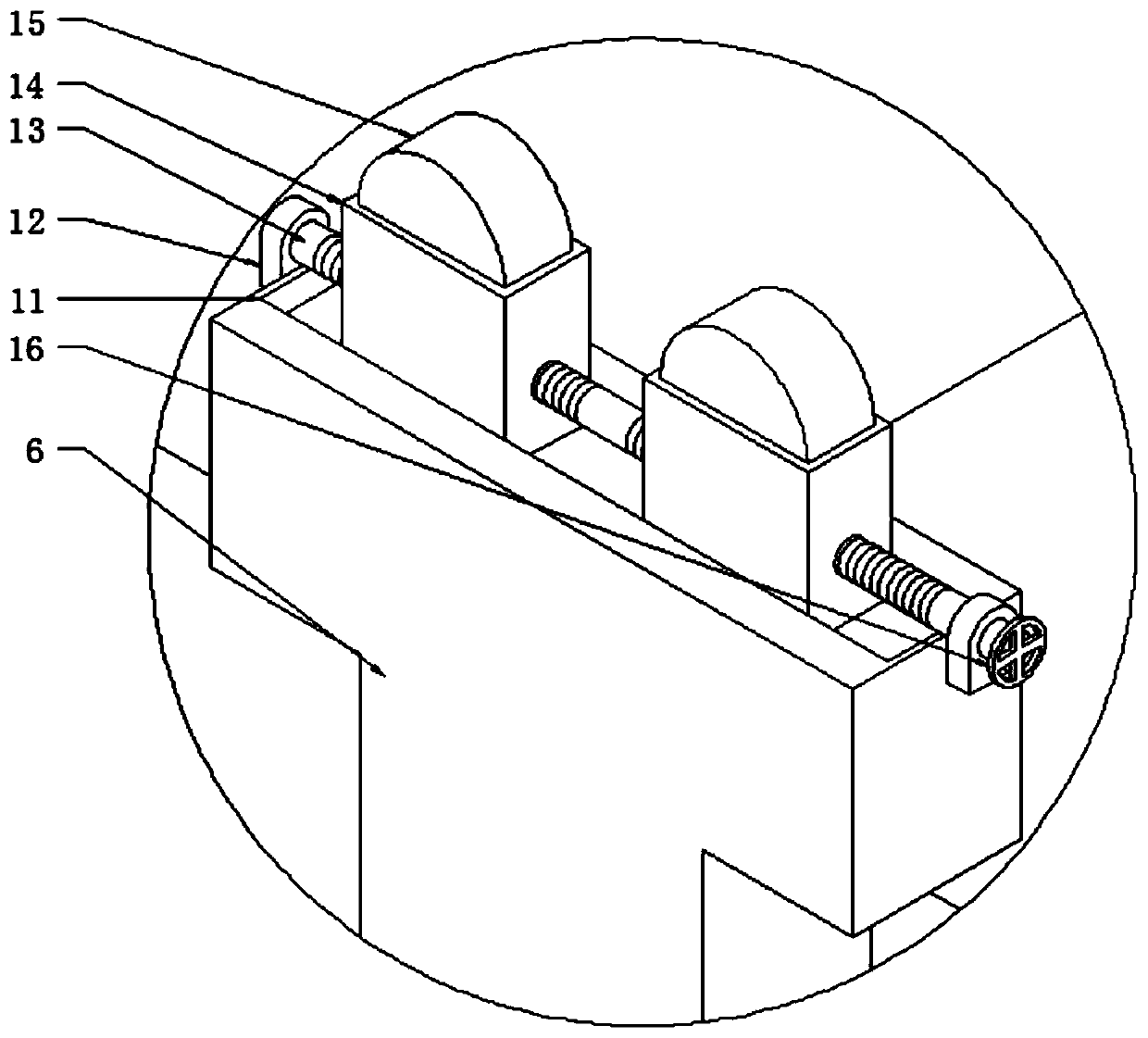

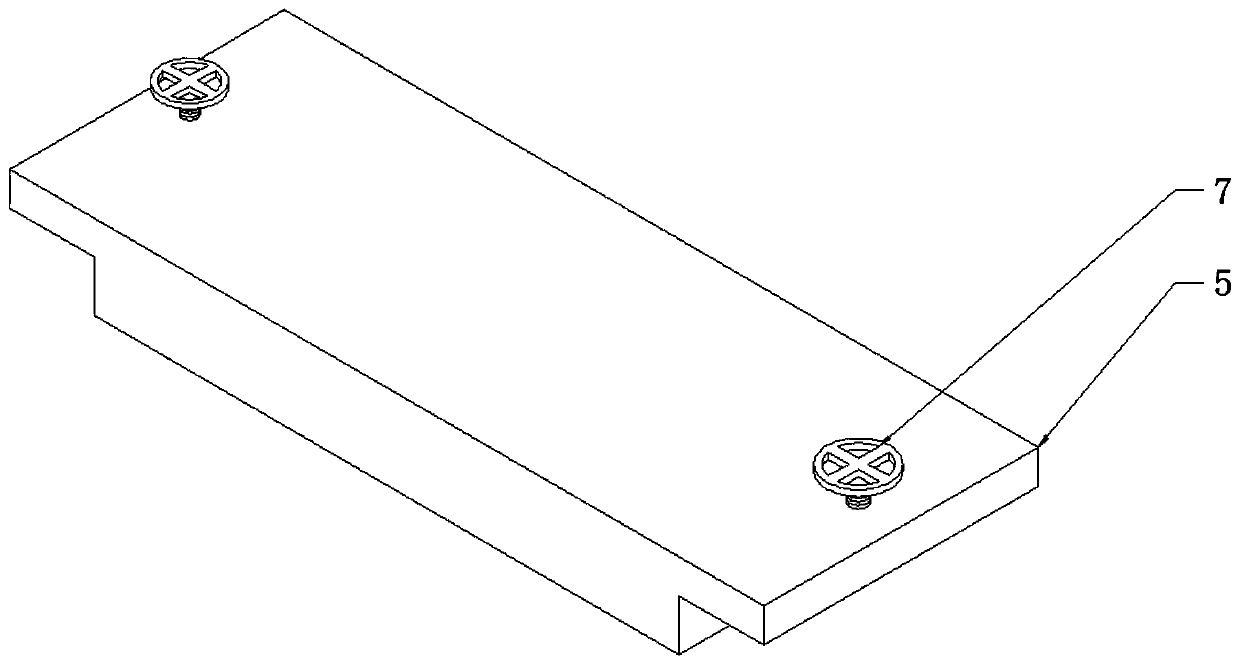

[0034] In a typical implementation of the present application, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a thermal power plant steam turbine maintenance device is proposed.

[0035] It includes at least two supporting seats, and each supporting seat includes two rollers 15 parallel to the axis. The rollers are used to support the steam turbine with the outer circumference of the shaft of the steam turbine. The rollers are installed on the On the support seat, the screw slider mechanism is used to adjust the distance between the axes of the two rollers, and is used to match the shafts of steam turbines with different diameters; at least one bottom of the support seat is equipped with a sliding pair, which is used to adjust the support seat. The distance from other support bases; a support plate is correspondingly installed under the support base, and the support base equipped with a sliding pair is mounted on the support plate through the sliding pair;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com