Automated moxa cone packaging machine

A kind of Ai-pillar packaging and rack technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of low packaging quality and production efficiency, low production efficiency, difficult to arrange neatly, etc., to ensure sealing and packaging. Efficiency, the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

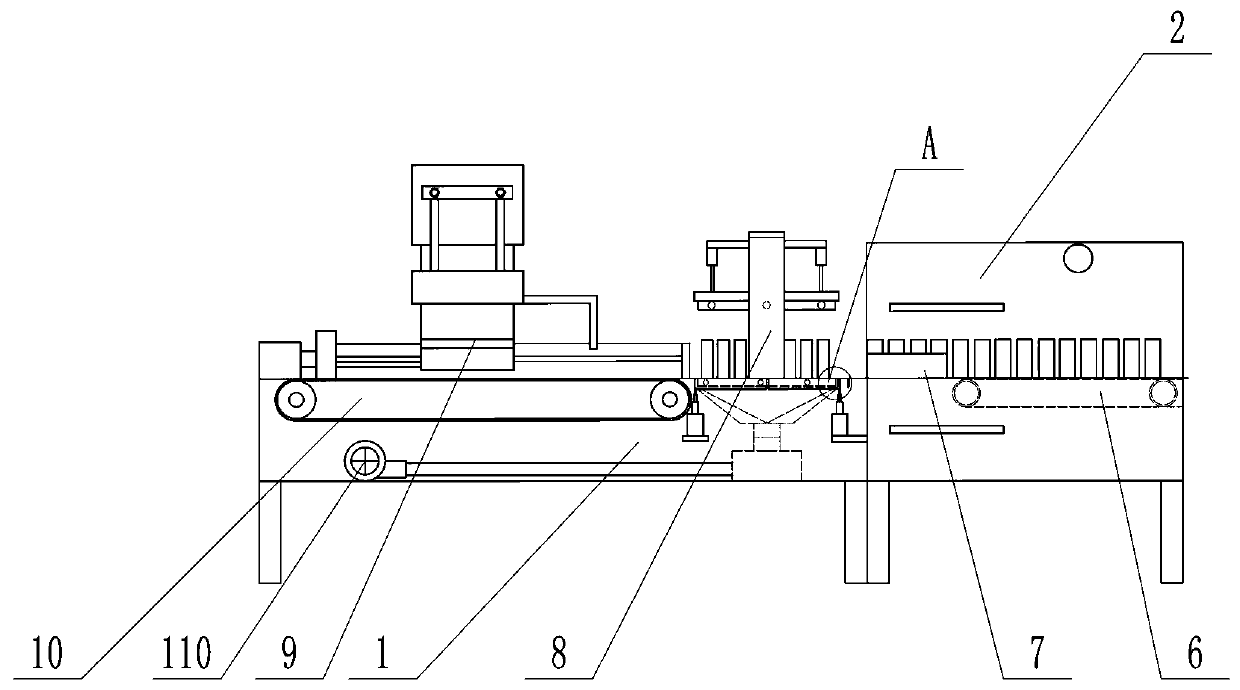

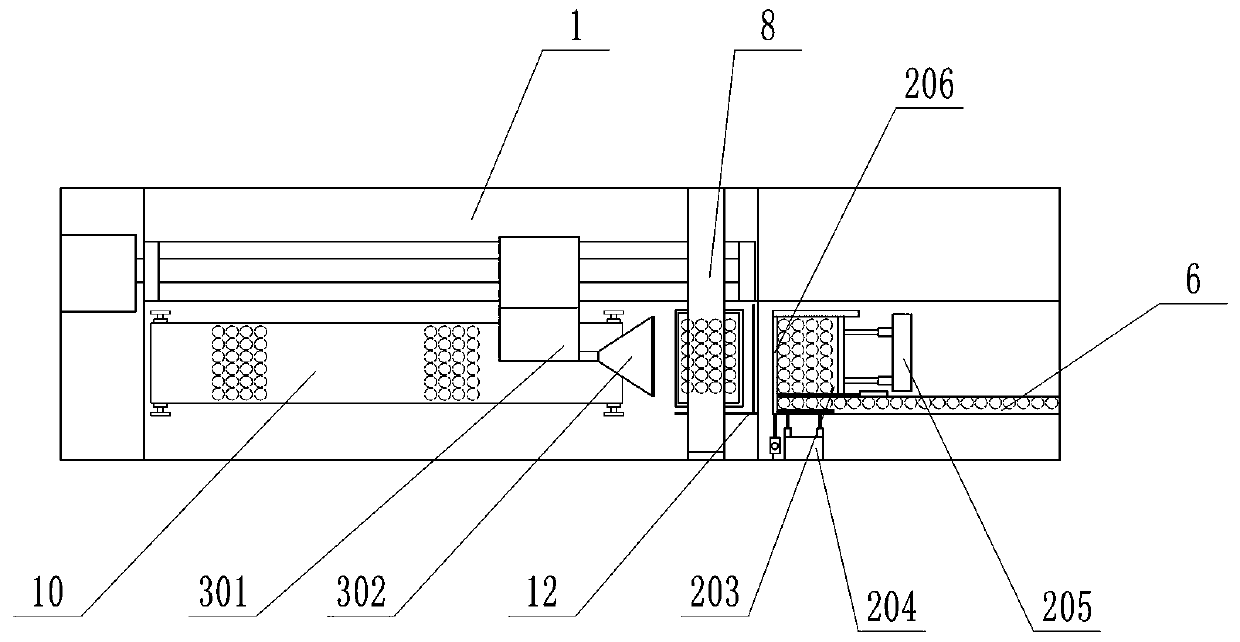

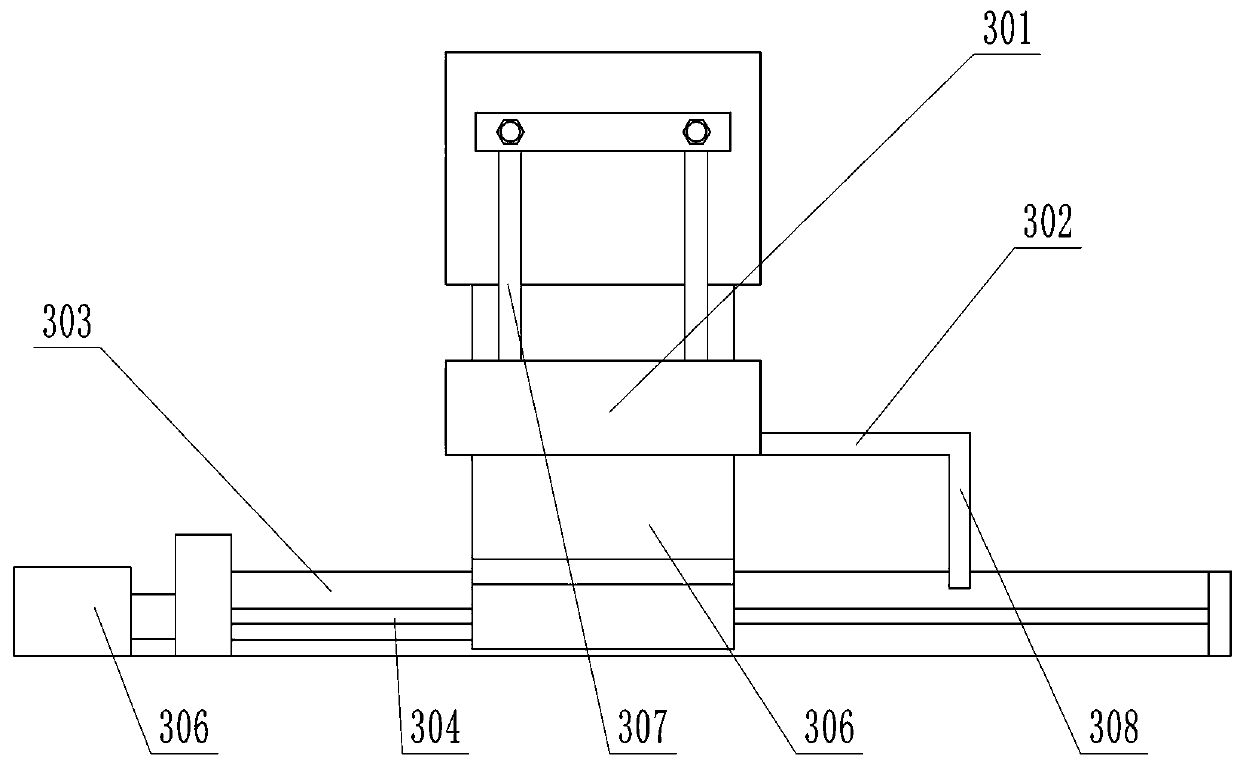

[0028] Such as Figure 1-9 Shown, a kind of automatic moxa pillar packing machine comprises frame 1, and on the frame along the moxa pillar conveying direction, is installed with feeding belt conveyor 6, the film feeding mechanism 2 that is used to convey heat-shrinkable adhesive film, is used for moxa The pendulum mechanism 7 for placing the pillars into a tray, the material transfer mechanism 9 for transferring the moxa pillar trays, the thermoplastic sealing mechanism 8 for plastic sealing the heat-shrinkable film on the surface of the moxa pillar trays, the feeding belt conveyor 10, and the film feeding mechanism 2 includes the outer frame 21, the supporting film roller 22, the laminating shaft 23, the perforating needle gun 24, the film feeding rubber roller 25, the film pressing rubber roller 26, the film feeding swing rod roller 27, the film feeding swing rod positioning shaft 28, the Membrane mechanism 3, film separation rod 31, steering drum 32, triangular plate 33, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com