Blade boundary layer suction jet device

A technology of a jet device and a boundary layer, which is applied to the components of a pumping device for elastic fluids, fluid flow, non-variable-capacity pumps, etc., can solve the problems of unsustainable jet flow, inconvenient control of the size and direction of the jet, etc. , to achieve the effect of convenient control and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

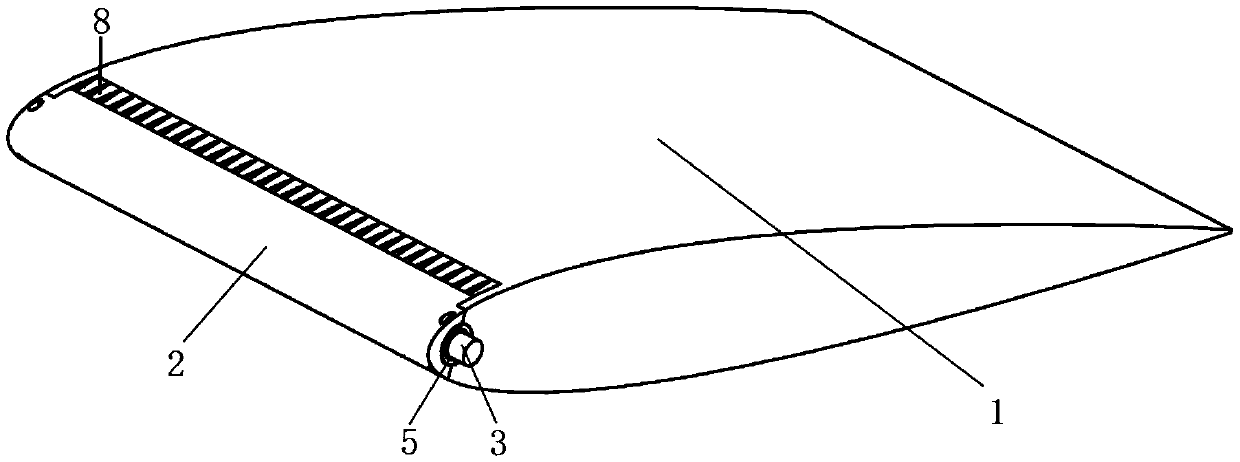

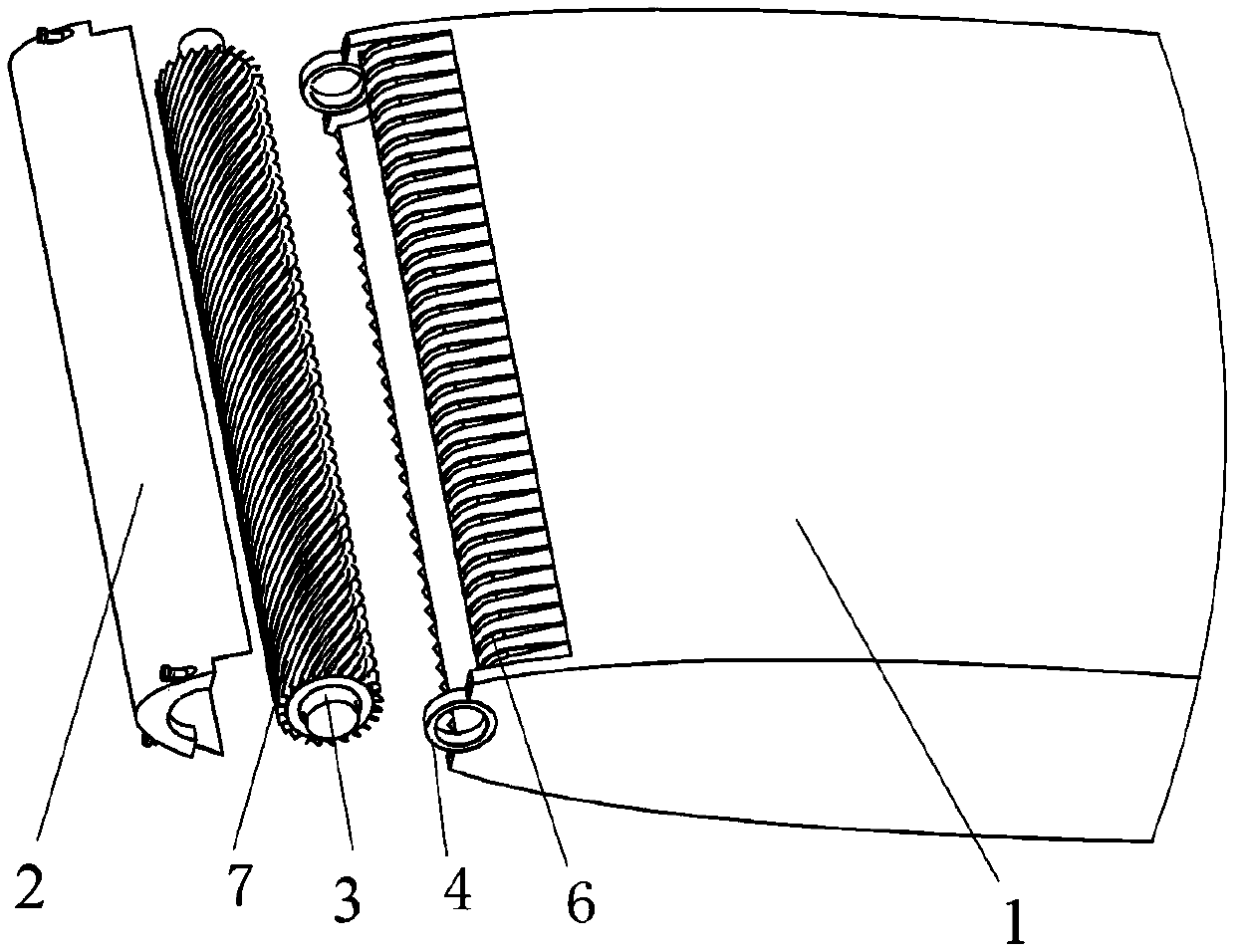

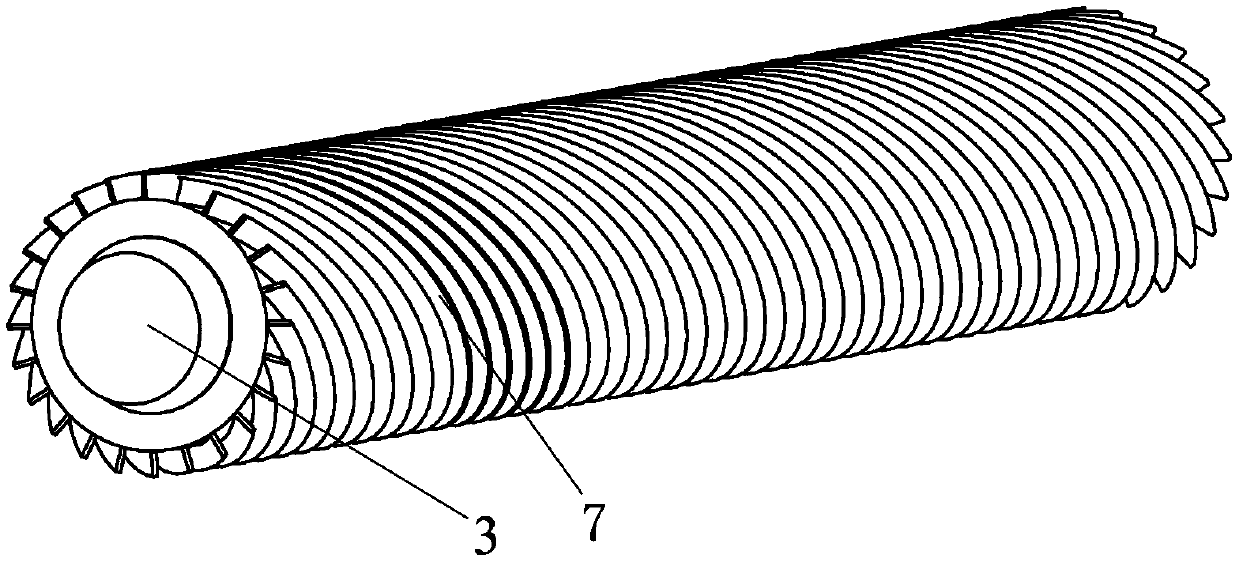

[0022] The invention provides a blade boundary layer suction jet device, such as figure 1 and figure 2 As shown, it includes a blade main body 1 , a rotor 3 rotatably arranged on the airflow inlet and outlet ends of the blade main body 1 , and an arc-shaped blade front edge 2 that covers the rotor 3 and is fixedly connected with the blade main body 1 . The upper surface and the lower surface of the blade main body 1 are arc-shaped structures (the descriptions of directions such as "up, down, clockwise, counterclockwise" in this embodiment are all for the accompanying drawings in the specification, and are not intended to limit the present invention ). Both sides of the airflow inlet and outlet of the blade main body 1 are respectively fixed with a bearing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com