Machine head of snow making machine

A machine head and snowmaking technology, which is applied in the fields of ice making, lighting and heating equipment, leisure ice making, etc., can solve the problems of reducing the service life of the snow machine head, poor quality of snowmaking, and easy freezing, etc. The effect of long service life, stable snow making, and quick contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is further explained:

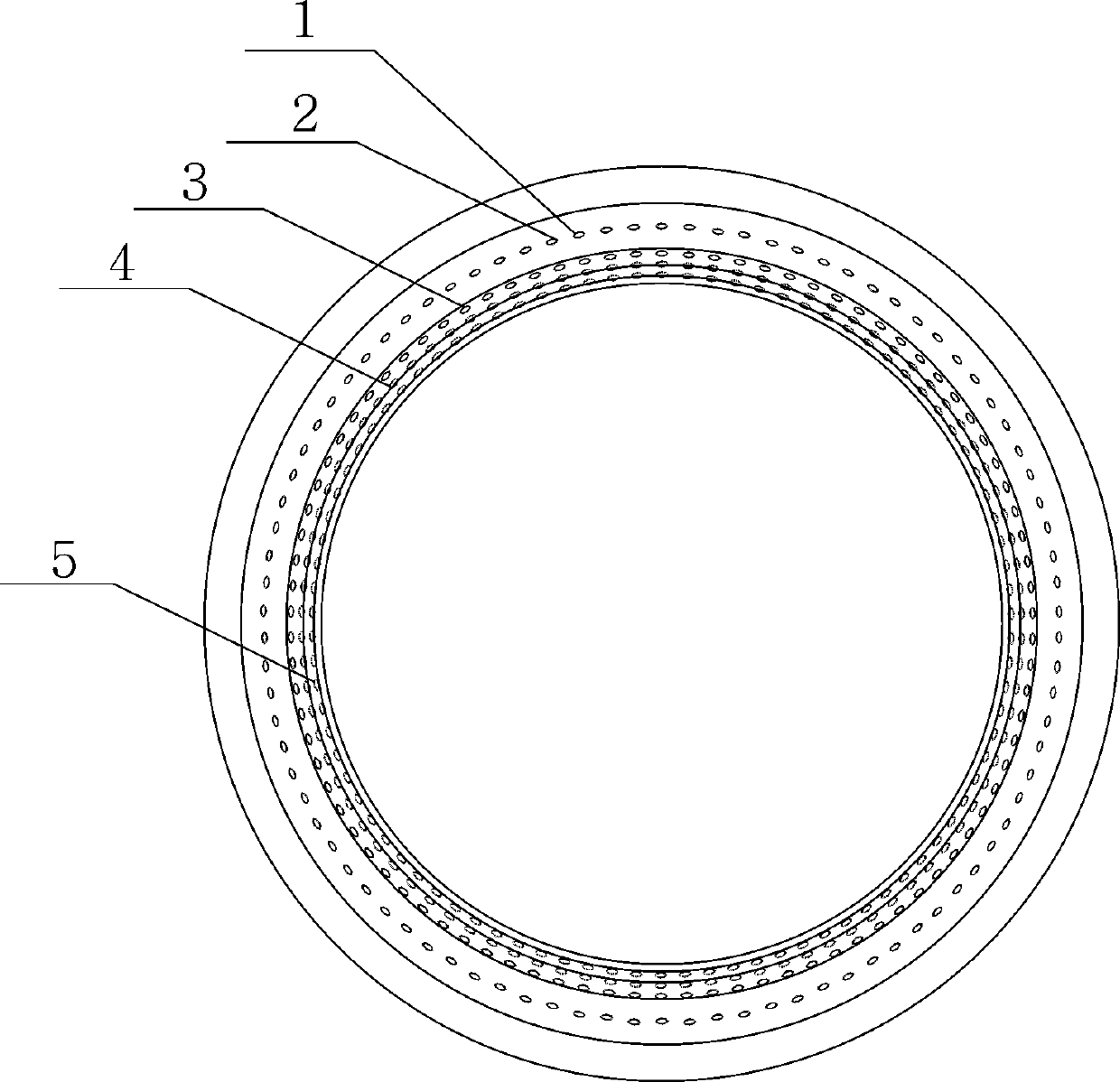

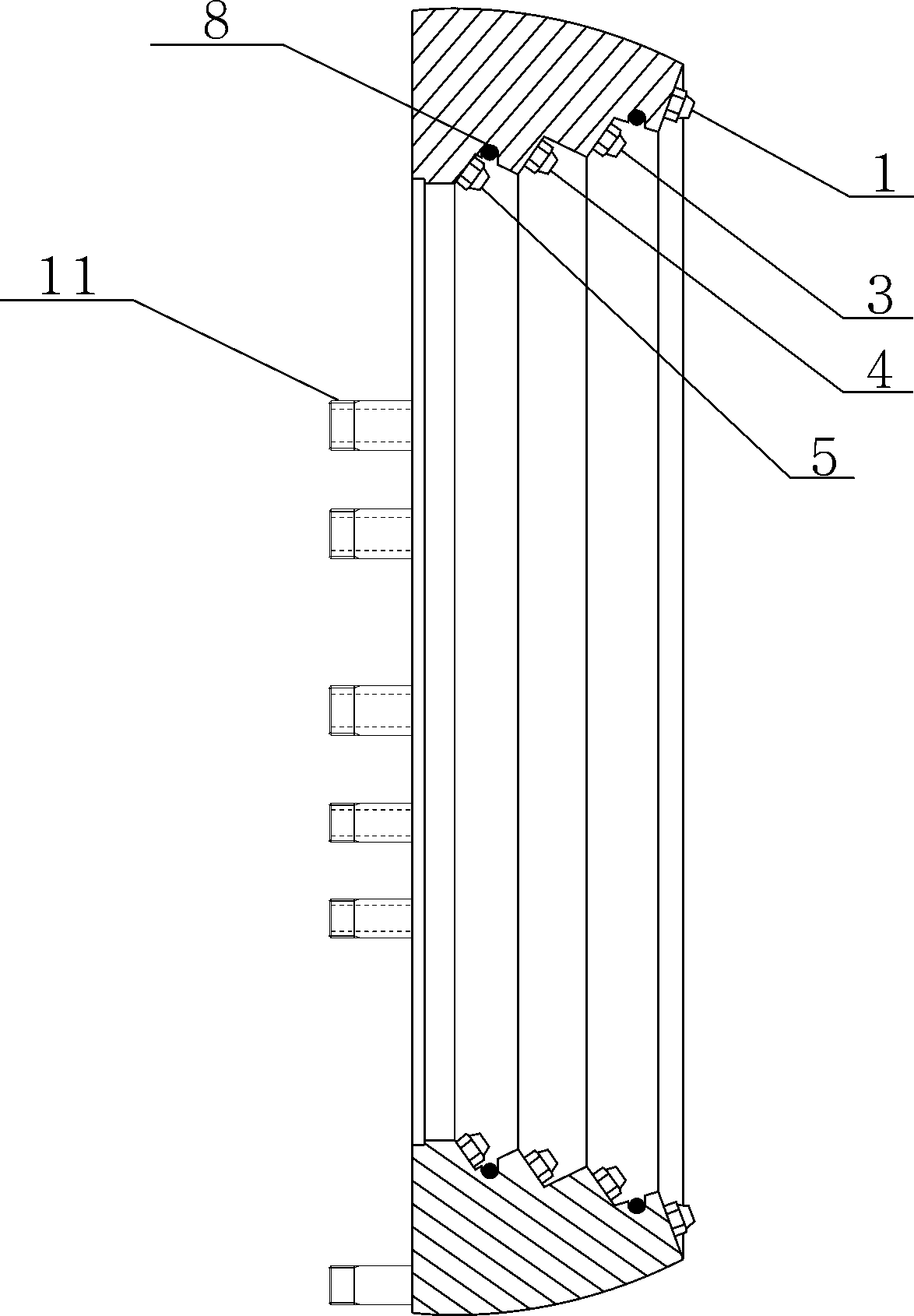

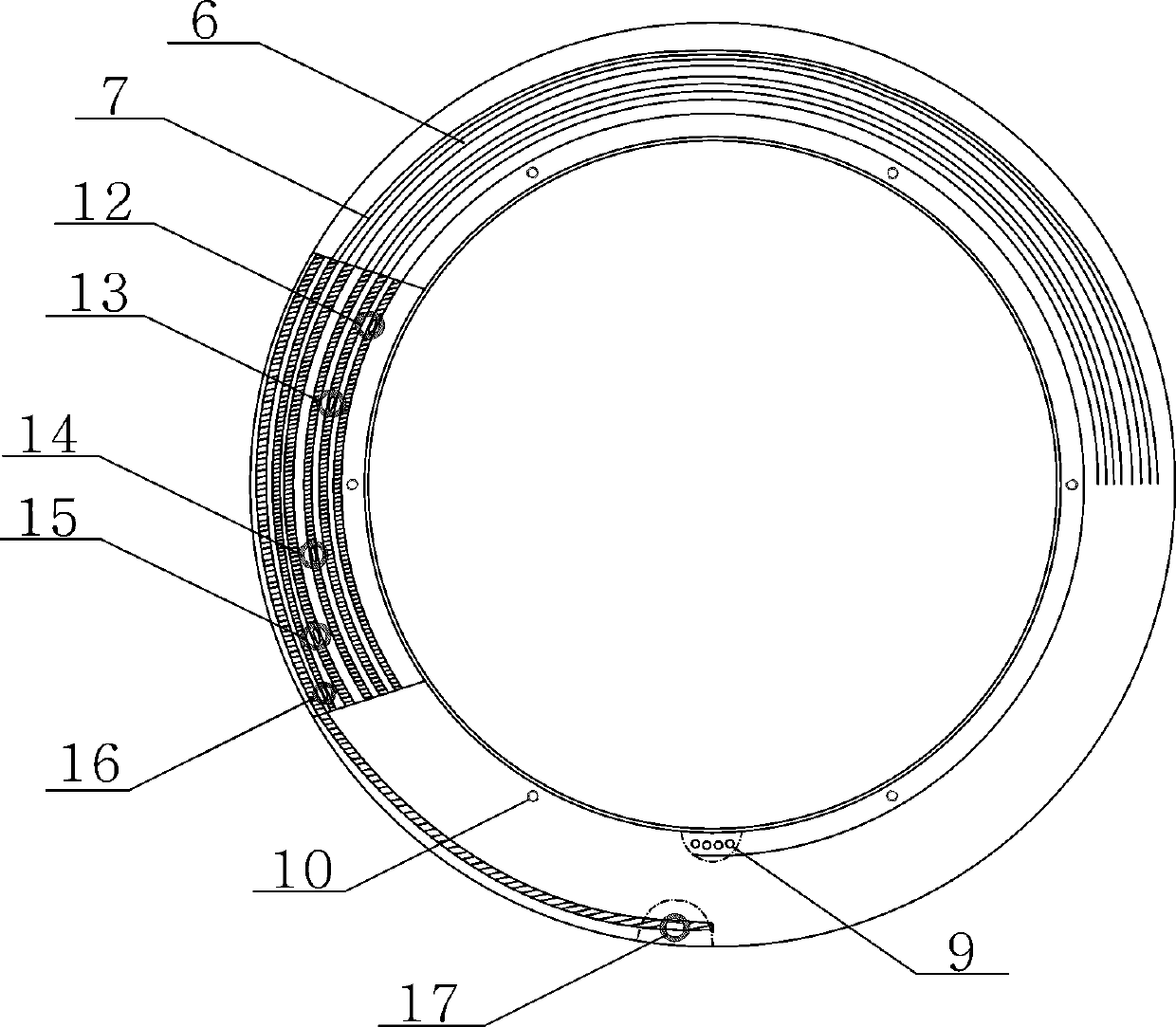

[0016] according to Figure 1 to Figure 3 As shown, a snowmaking machine head includes a head body, a nuclear nozzle 1, a water nozzle, a high-pressure water tank 6, a high-pressure air tank 7, and a heating ring 8; the material of the head body is a special aluminum alloy resistant to low temperature, There are four screw holes for installing nozzles on the front of the machine head body, a total of 355. There are 45 nuclear nozzles 1 and 45 outermost water nozzles 2 installed on the outermost channel of the front of the machine head body. The nuclear nozzles 1 and the outermost water nozzles 2 are arranged alternately. 89 outer second water nozzles 3 are installed in the second outer channel of the front of the machine head body, 88 inner second water nozzles 4 are installed in the second inner channel of the front of the machine head body, and 88 inner se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com