Metering equipment fault detection method based on AR technology

A metering equipment and fault detection technology, which is applied in the direction of calculation, measuring devices, and measuring electrical variables, etc., can solve the problems of limited technical level and experience of meter reading operation and maintenance personnel, high operation and maintenance costs, and failure to eliminate hidden dangers of equipment in time. Achieve the effect of improving operation and maintenance work efficiency and reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

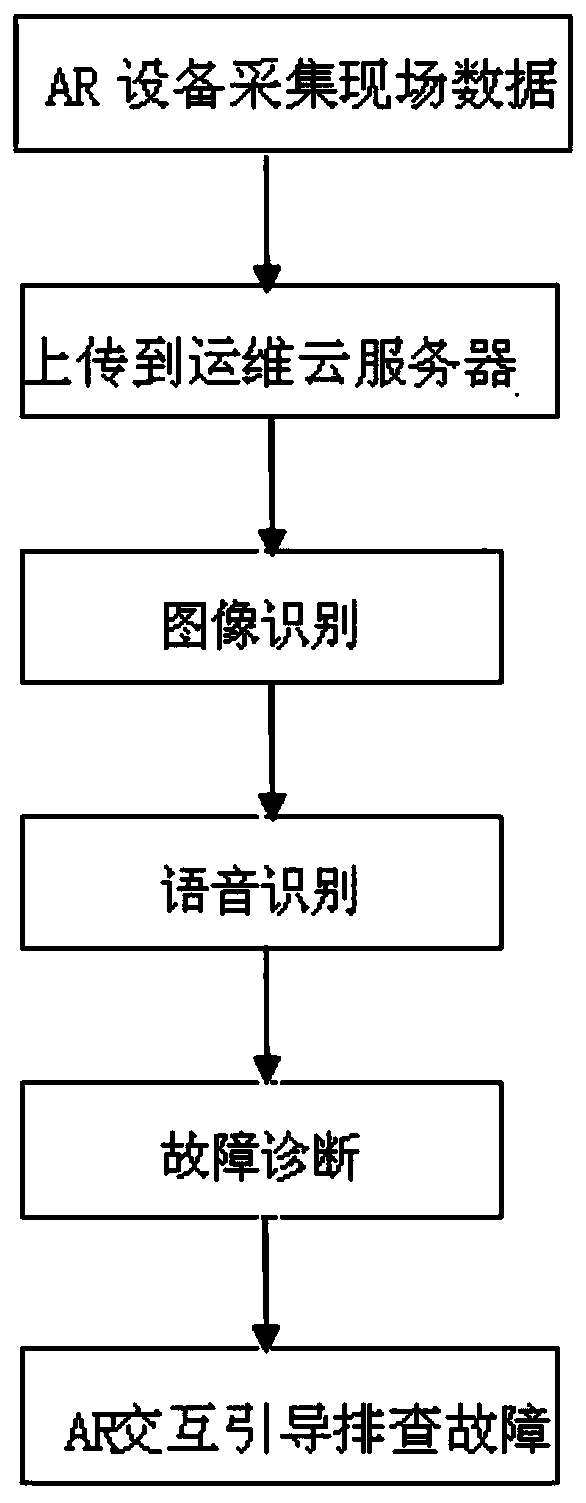

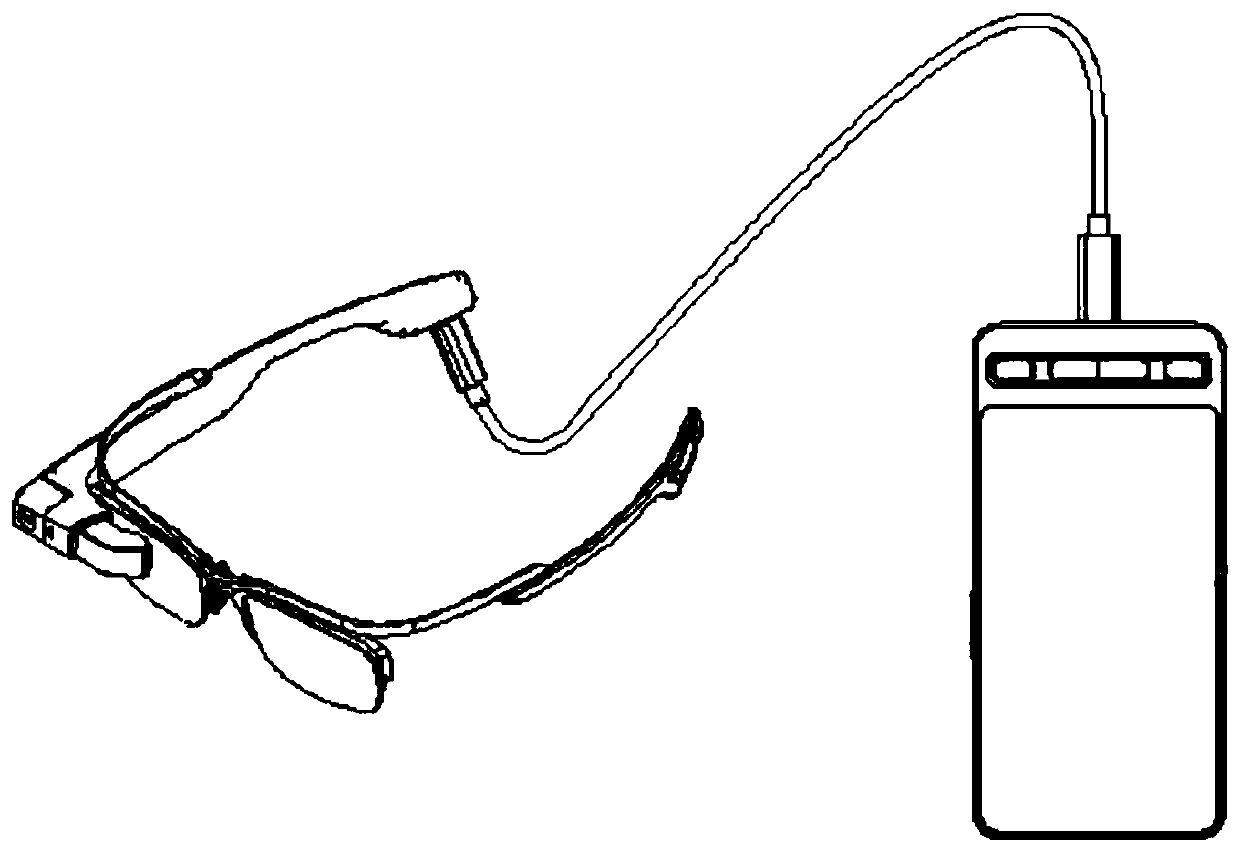

[0027] Example 1: Such as Figure 1-4 As shown, an AR technology-based fault detection method for metering equipment includes the following steps:

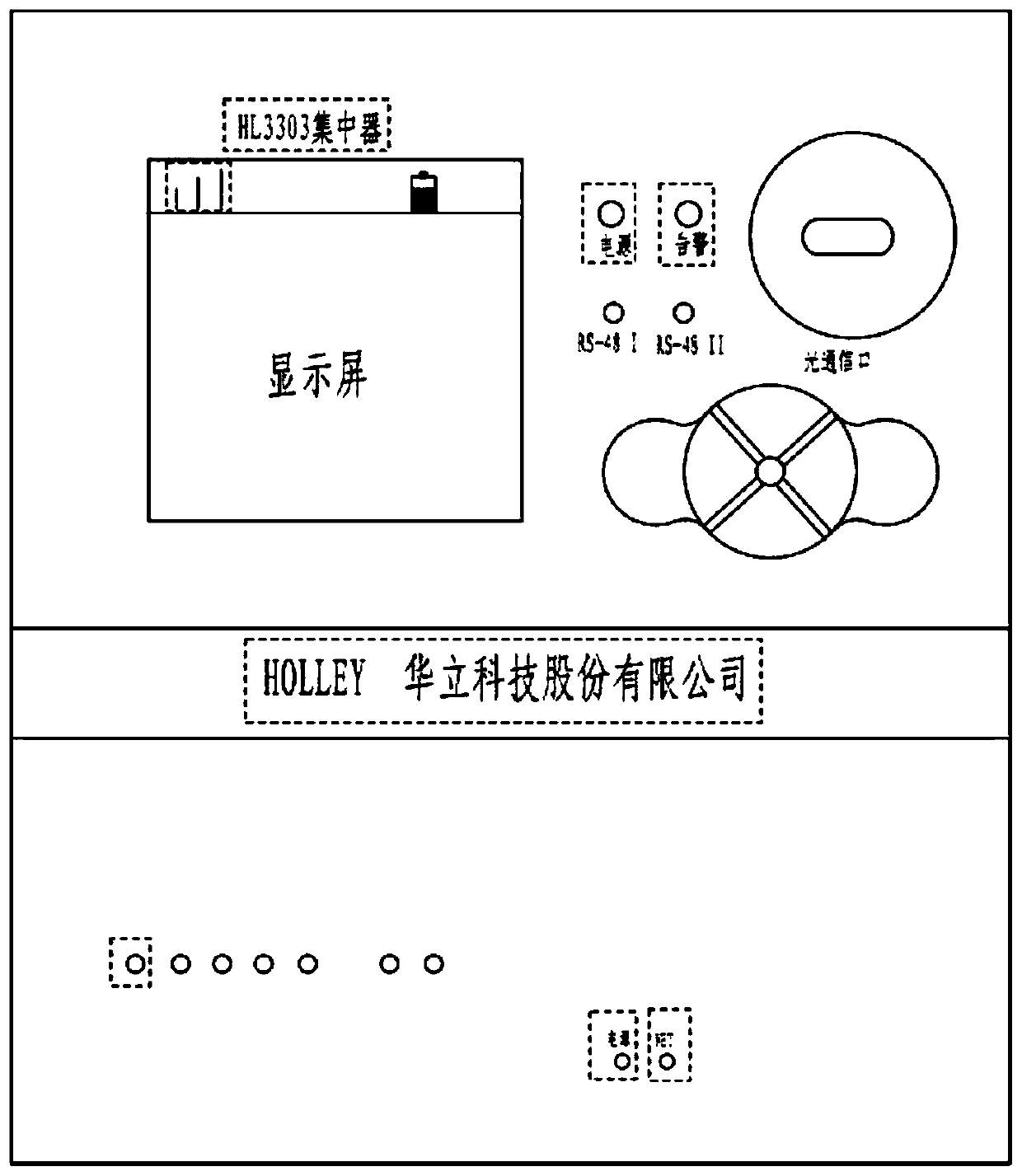

[0028] (1) Offline construction of image recognition engine: Collect more than 5,000 pieces of on-site equipment image material marking features, and import more than 5,000 pieces of on-site equipment image materials through image deep learning training tools. The image materials include normal operation of the on-site equipment and various fault conditions. , Mark the characteristics of each picture, the characteristics of each picture include the name of the manufacturer, model, power light, running light, LCD screen and barcode, and use the YOLO algorithm to train the image recognition model of measurement equipment;

[0029] (2) Offline construction of fault diagnosis expert knowledge base: according to the standardization and safety requirements of power equipment operation and maintenance operations, establish a standardized know...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com