Internet of Things intelligent weighing integrated management platform and management method

A technology of comprehensive management and Internet of Things, applied in the comprehensive management platform and management field of intelligent weighing of Internet of Things, which can solve the problems of cheating in personnel communication, high error rate, and low operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

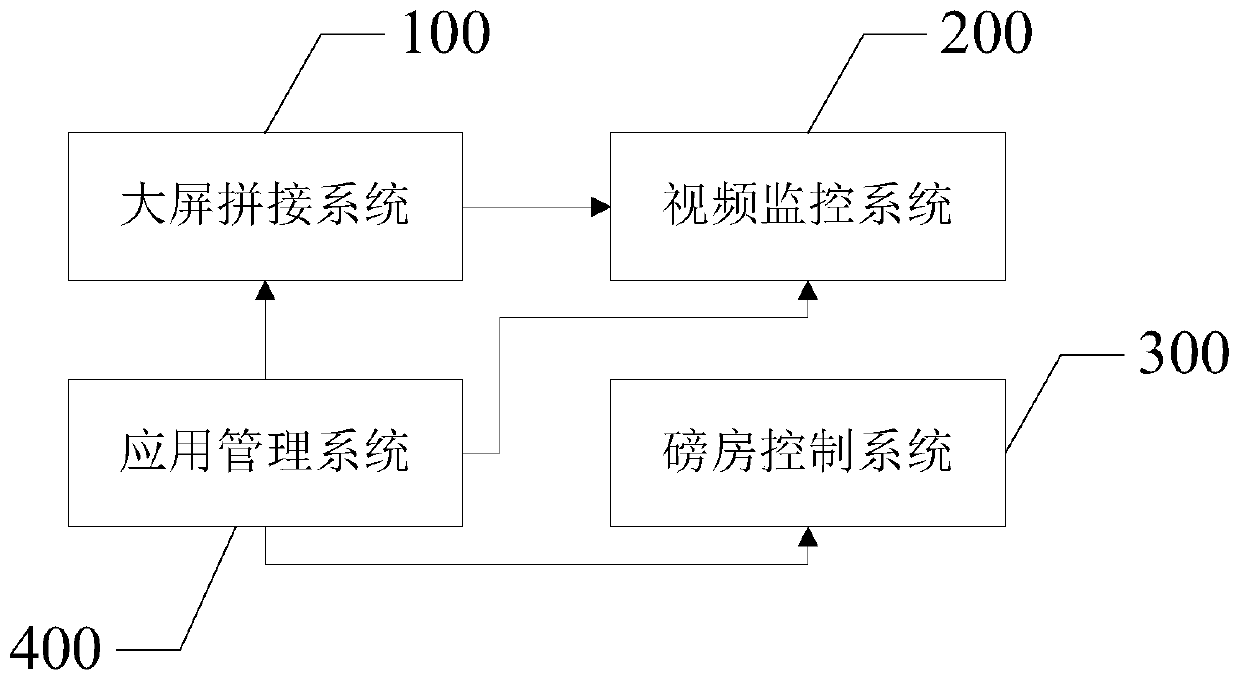

[0056] Such as Figure 1-3 As shown, in the first embodiment of the present invention, a kind of Internet of Things intelligent weighing integrated management platform is provided, and the integrated management platform includes:

[0057] Large-screen splicing system 100, used for displaying, counting, updating and exporting weighing room data, pictures and video information;

[0058] Video monitoring system 200 is used to collect the real-time scene in the weighing room, and the real-time scene is sent to the described large-screen splicing system 100 synchronously by video information;

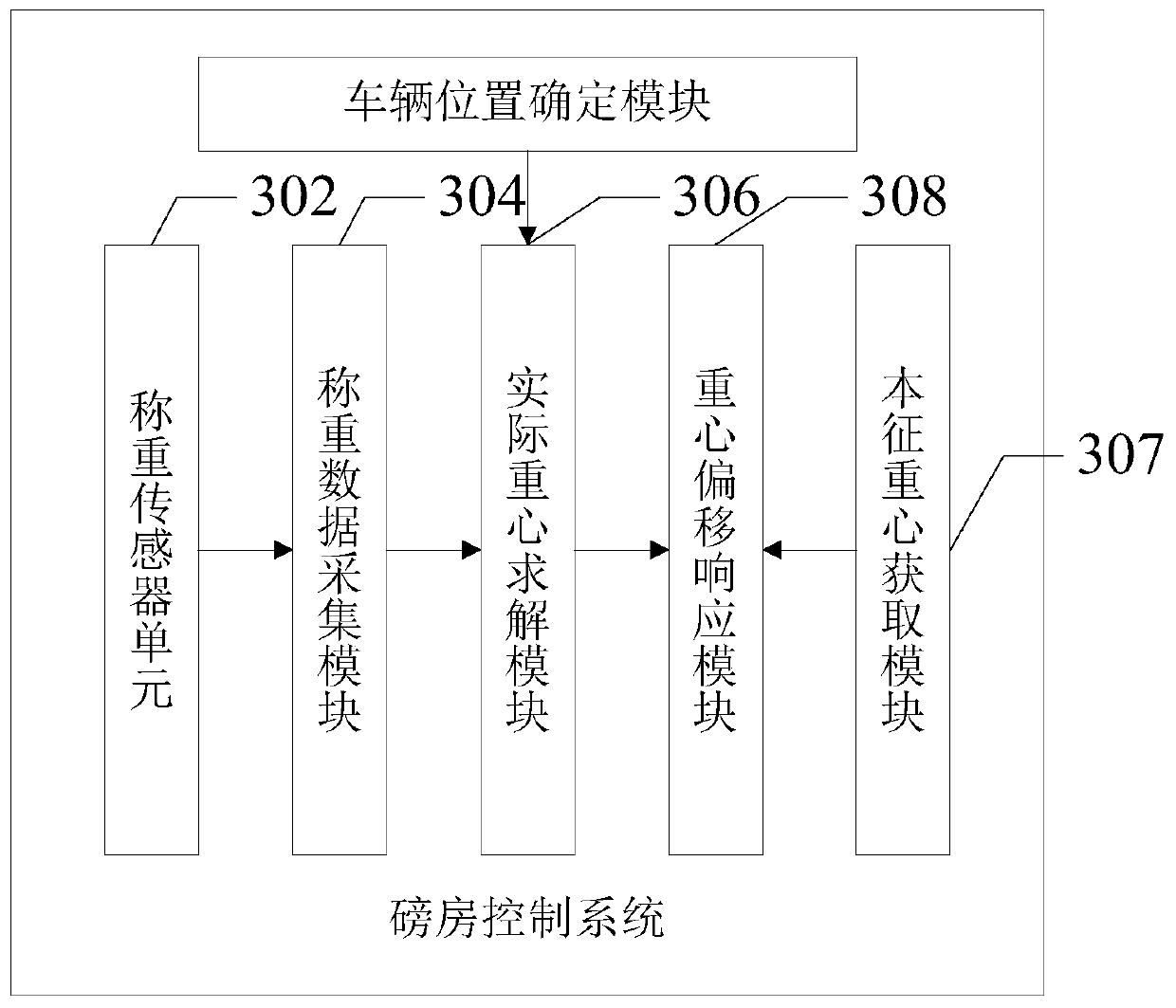

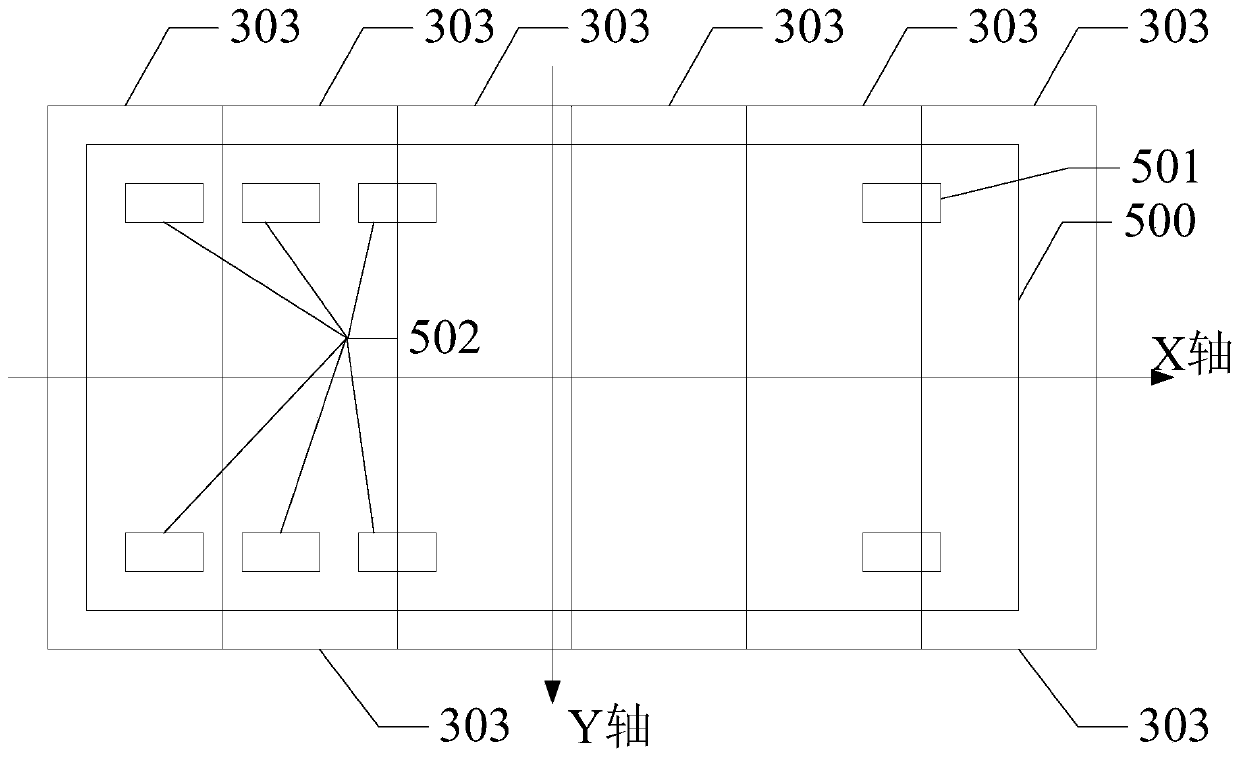

[0059] The weighing room control system 300 is used to collect the vehicle information and weighing data of the first vehicle 500; the vehicle information includes license plate information, the vehicle speed of the last scale and the vehicle and the approved load quality;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com