Glove manufacturing method and glove

A manufacturing method and glove technology, applied in the glove manufacturing method and the field of gloves, can solve problems such as affecting the smooth progress of work, damage to gloves, time-consuming and laborious, etc., to improve service life and use effect, easy and convenient to wear, and reduce cross-infection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

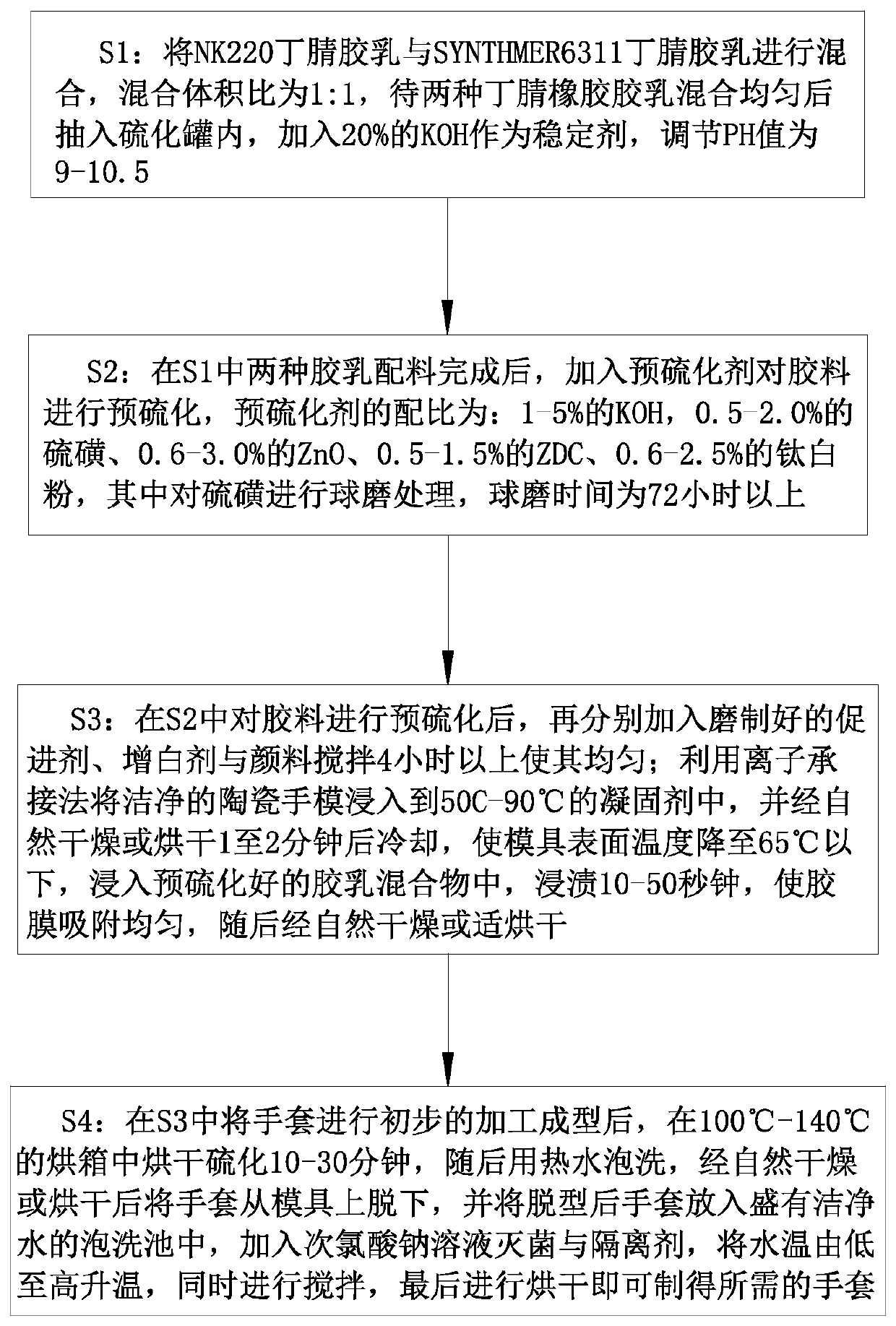

Method used

Image

Examples

Embodiment approach

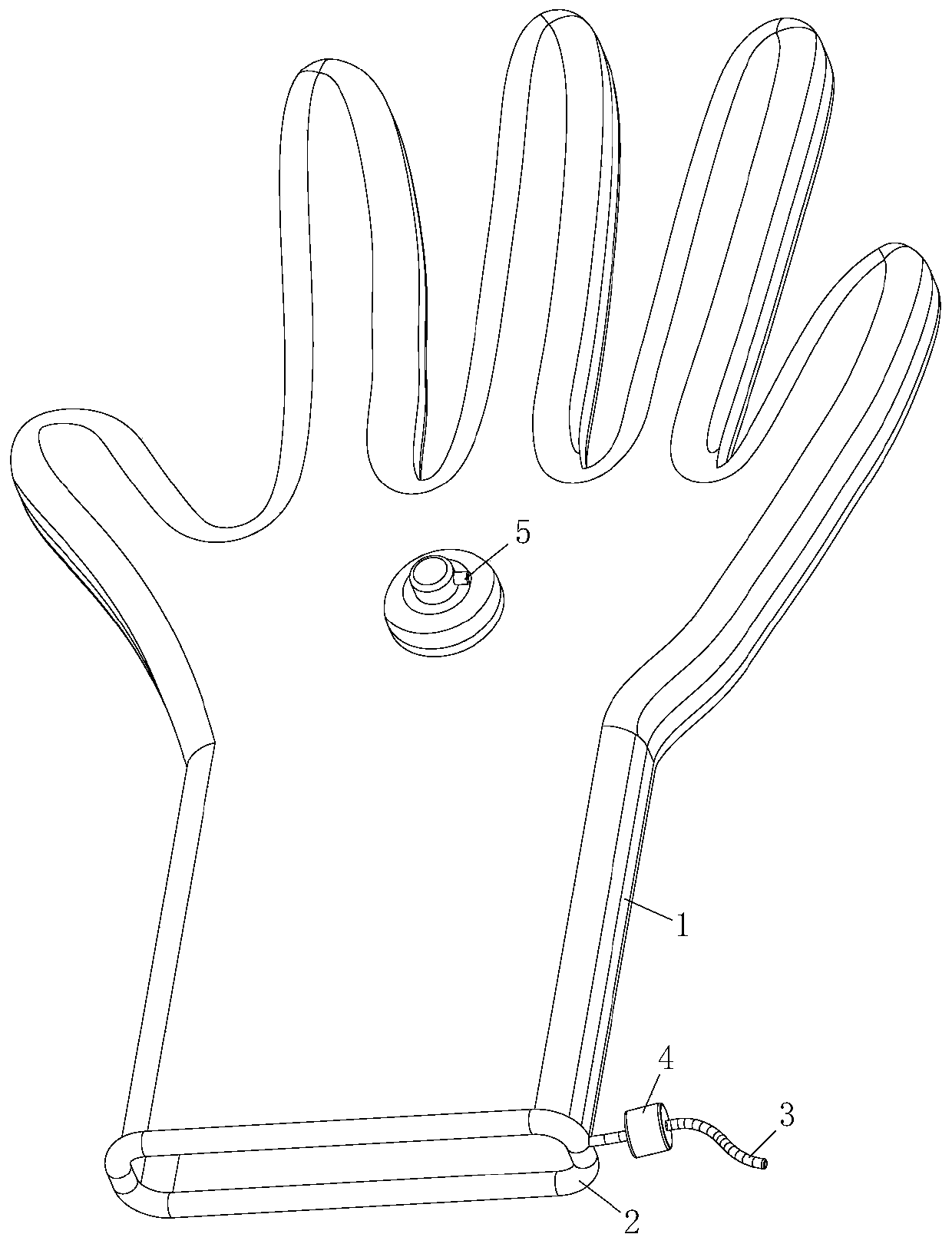

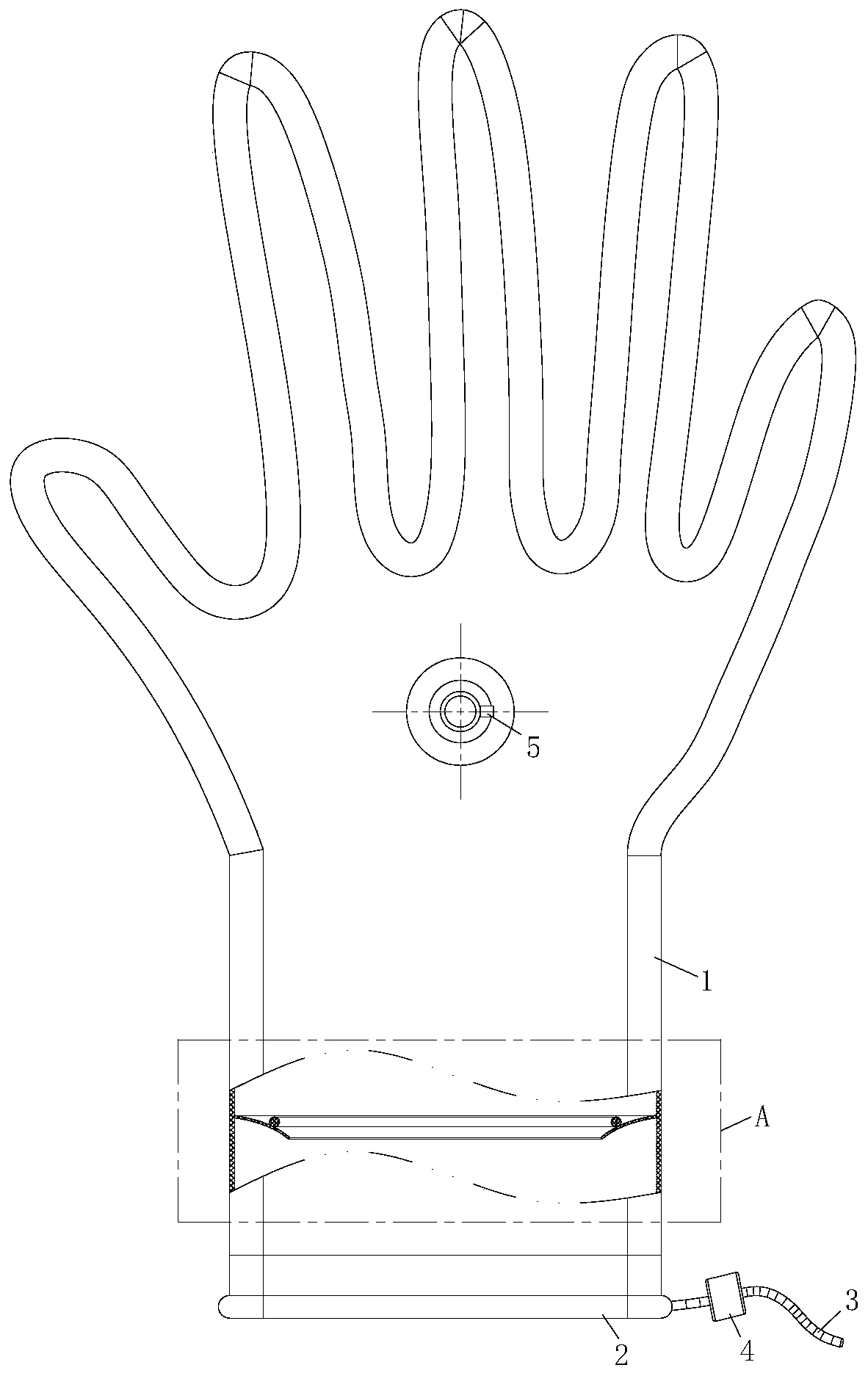

[0033] As an embodiment of the present invention, an annular sealing film 6 is provided on the side wall of the inner bottom of the sleeve body 1, the top end of the sealing film 6 is connected to the inner surface of the sleeve body 1, and the bottom end of the sealing film 6 can be Fitting with the user's arm, the opening shape of the sealing film 6 gradually shrinks from top to bottom; during work, when the hand is inserted into the glove, the bottom end of the sealing film 6 is attached to the user's arm, When the air pump pumps air through the inflatable tube 5 to the inside of the sleeve body 1, the sealing film 6 is adsorbed on the arm under the action of the air pressure inside the sleeve body 1, so that the sealing film 6 that is closely attached to the arm is opposite to the inside of the sleeve body 1. The space of the glove can be more effectively sealed to reduce the infiltration of external air from the sleeve body 1, so that the inner wall of the glove can fit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com