Punching die for louver slat

A curtain slat and punching technology, applied in wood punching, metal processing and other directions, can solve the problems of uneven force on the threading hole, edge collapse around the threading hole, easy displacement of punching holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

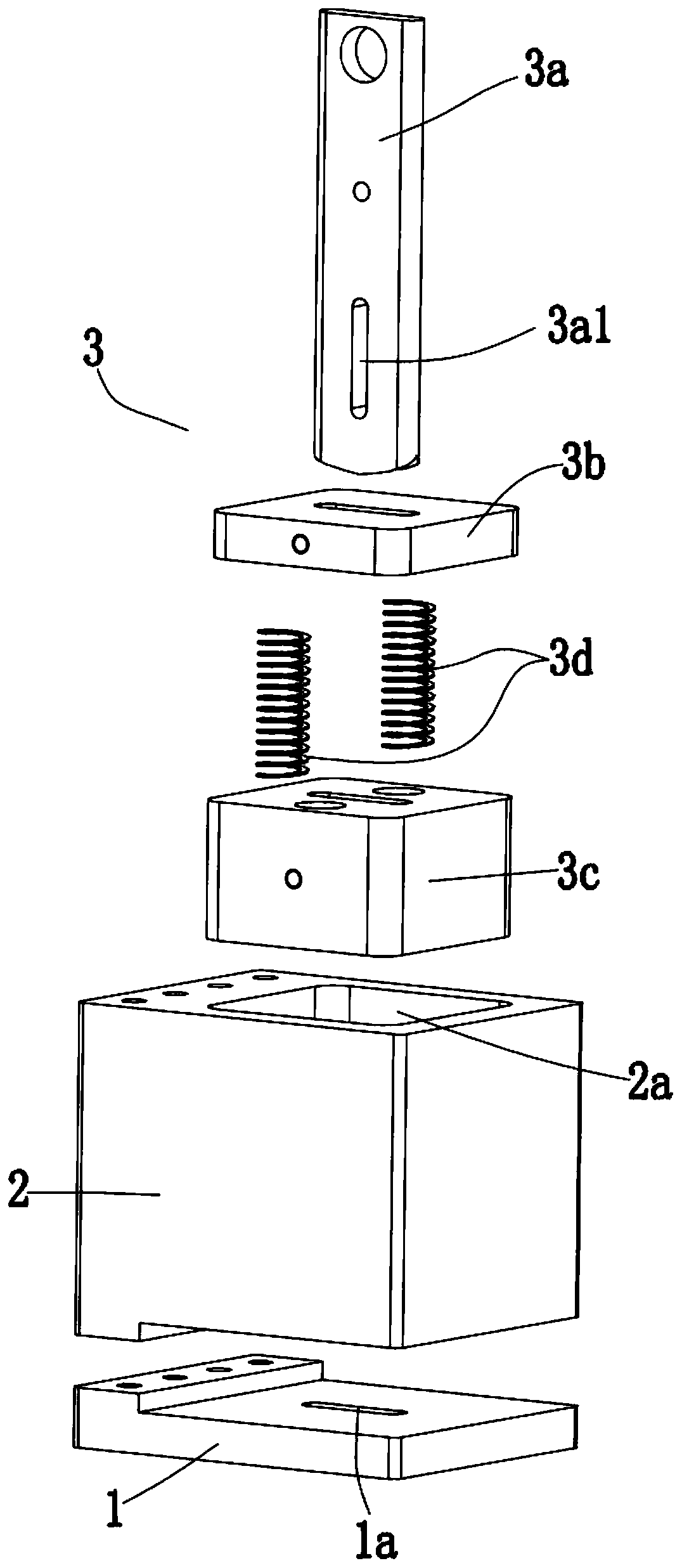

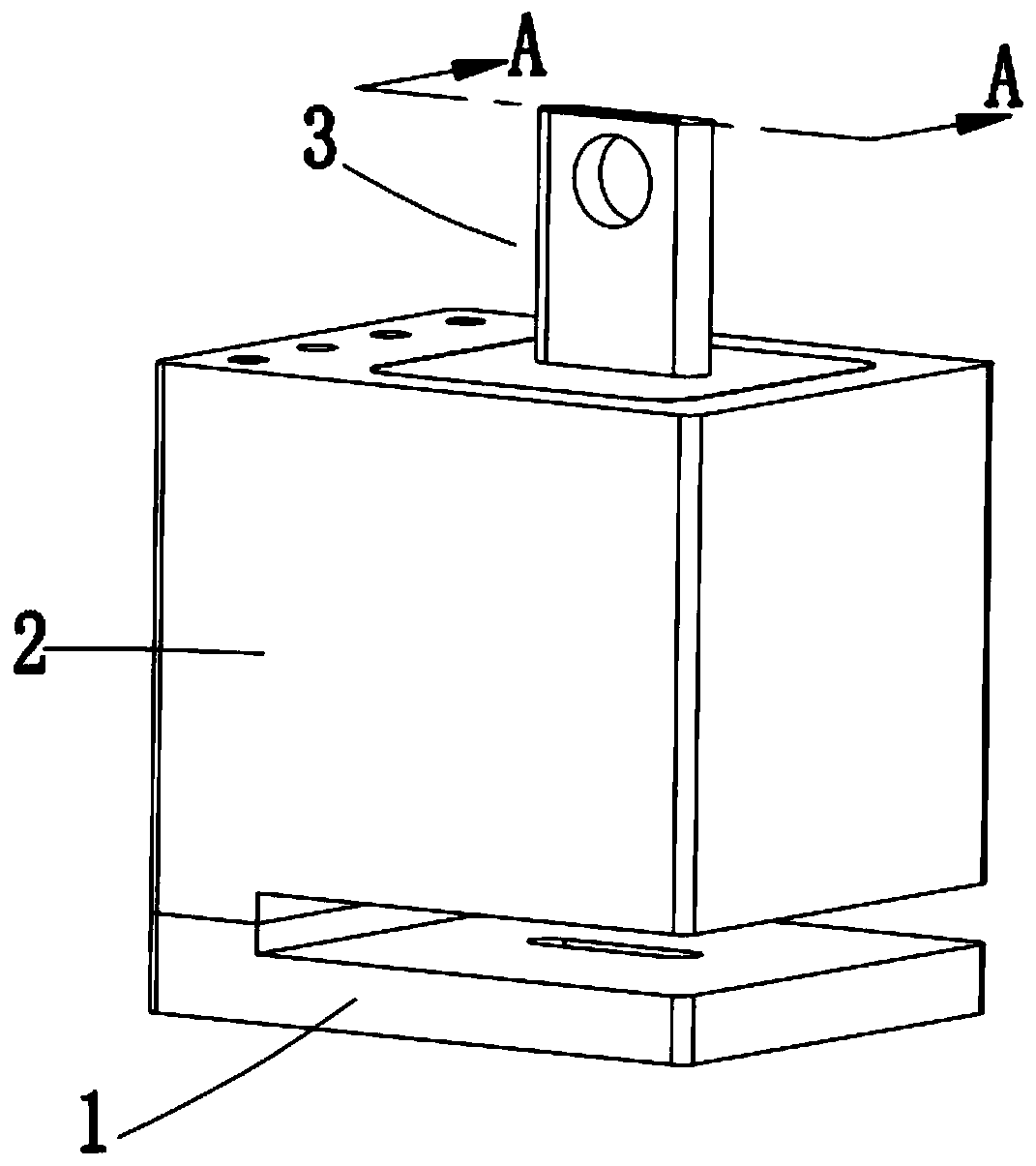

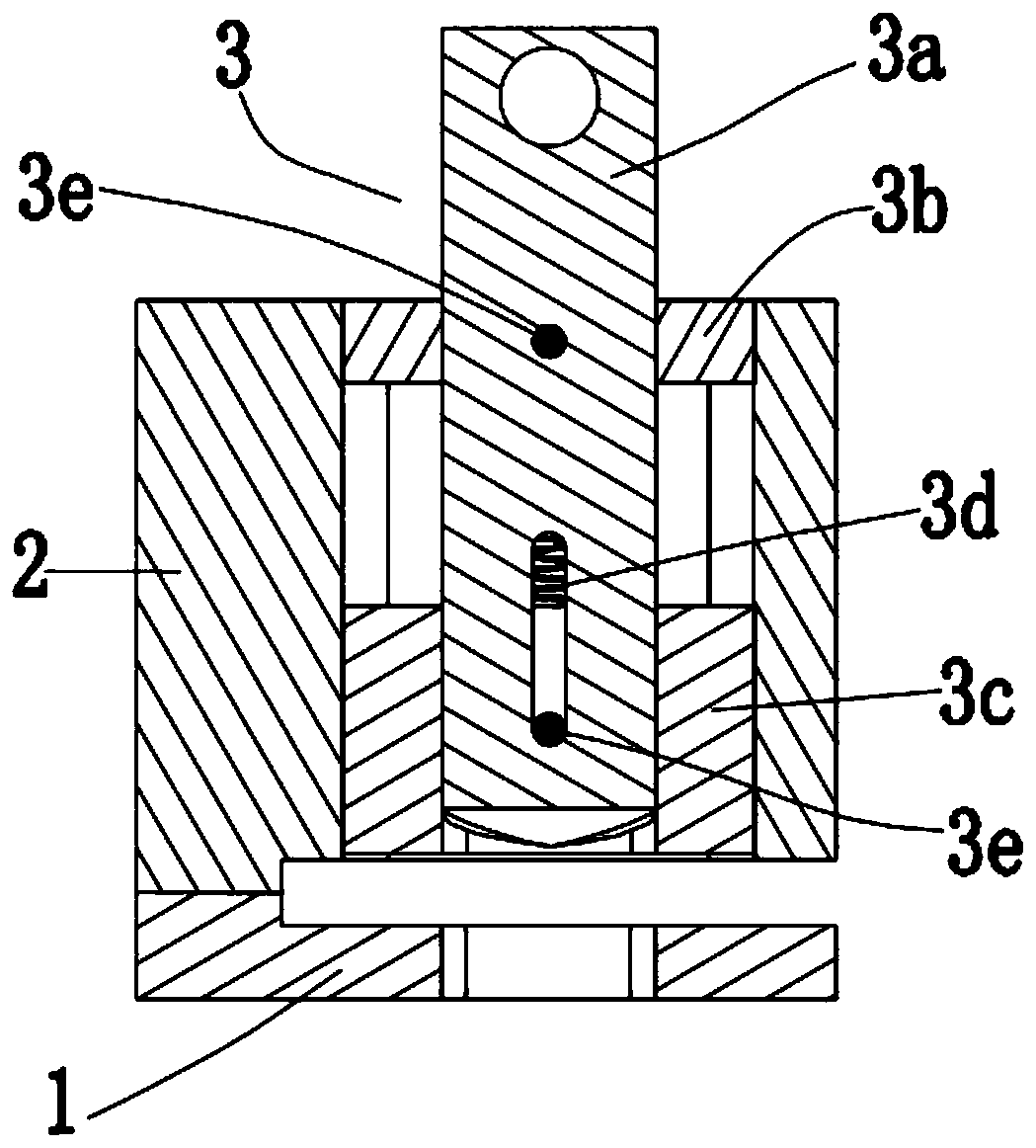

[0018] Such as Figure 1-4 As shown, a venetian curtain sheet punching die includes a static mold A1, a static mold B2 and a die assembly 3, the static mold B2 is arranged on the upper side of the static mold A1, and the static mold B2 and the static mold A1 A curtain placement area is provided, the die assembly 3 is arranged in the die accommodation space 2a on the static die B2, the die assembly 3 includes a punching knife 3a, a fixed module 3b and a moving module 3c, and the fixed module 3b passes through The pin shaft 3e is fixedly arranged on the upper part of the punching knife 3a, and the moving module 3c is slidably set in the limit groove 3a1 of the lower part of the punching knife 3a through the pin shaft 3e. spring 3d.

[0019] When punching through the rope hole, the punching device controls the die assembly 3 to move up and down in the die accommodation space 2a of the static die B2, the punching device controls the punching knife 3a of the die assembly 3 to move...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap