Kinematics assembly

A technology for moving components and guides, applied in vehicle components, transportation and packaging, heating/cooling equipment, etc., can solve the problem that the installation process cannot use process reliability configuration, etc., and achieve the effect of precise actuation and simple cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

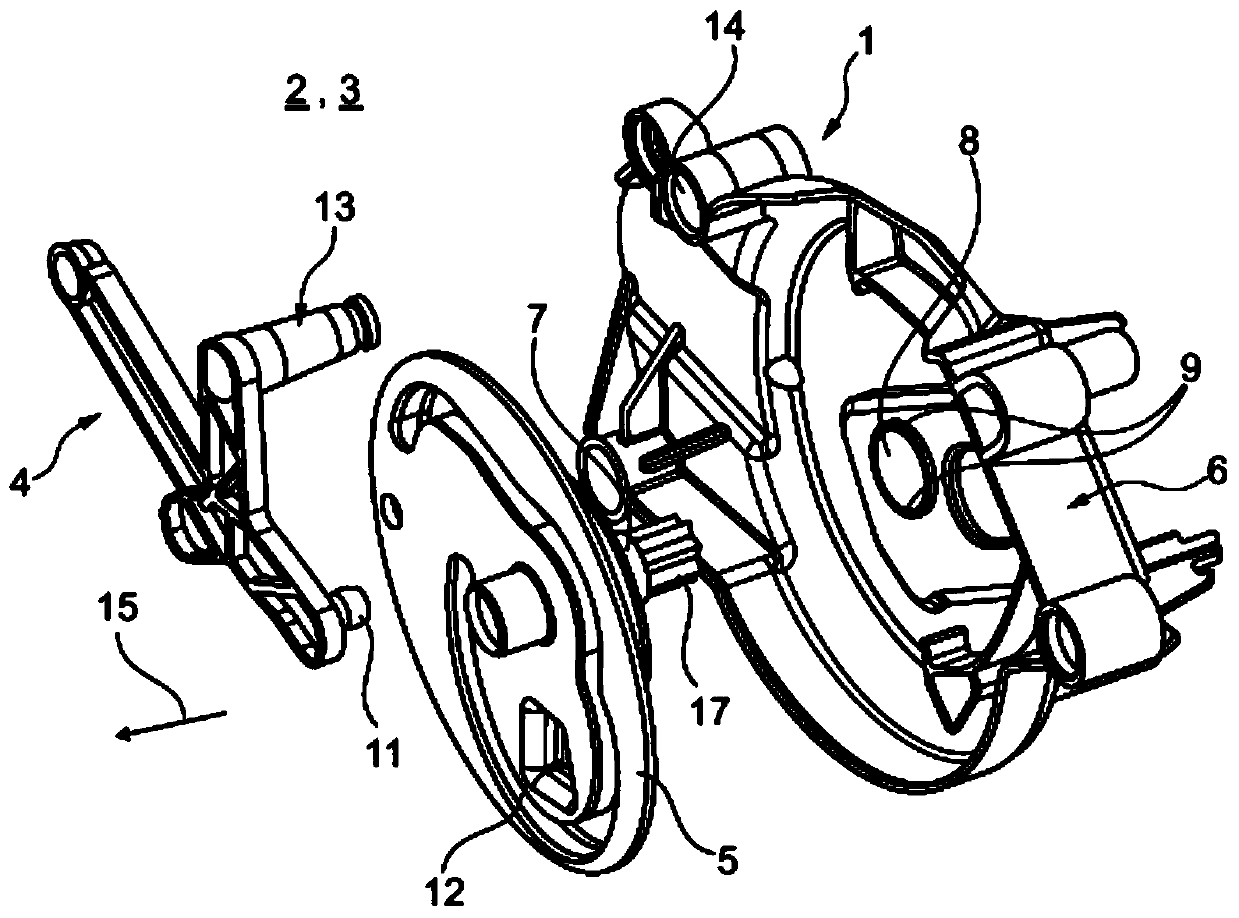

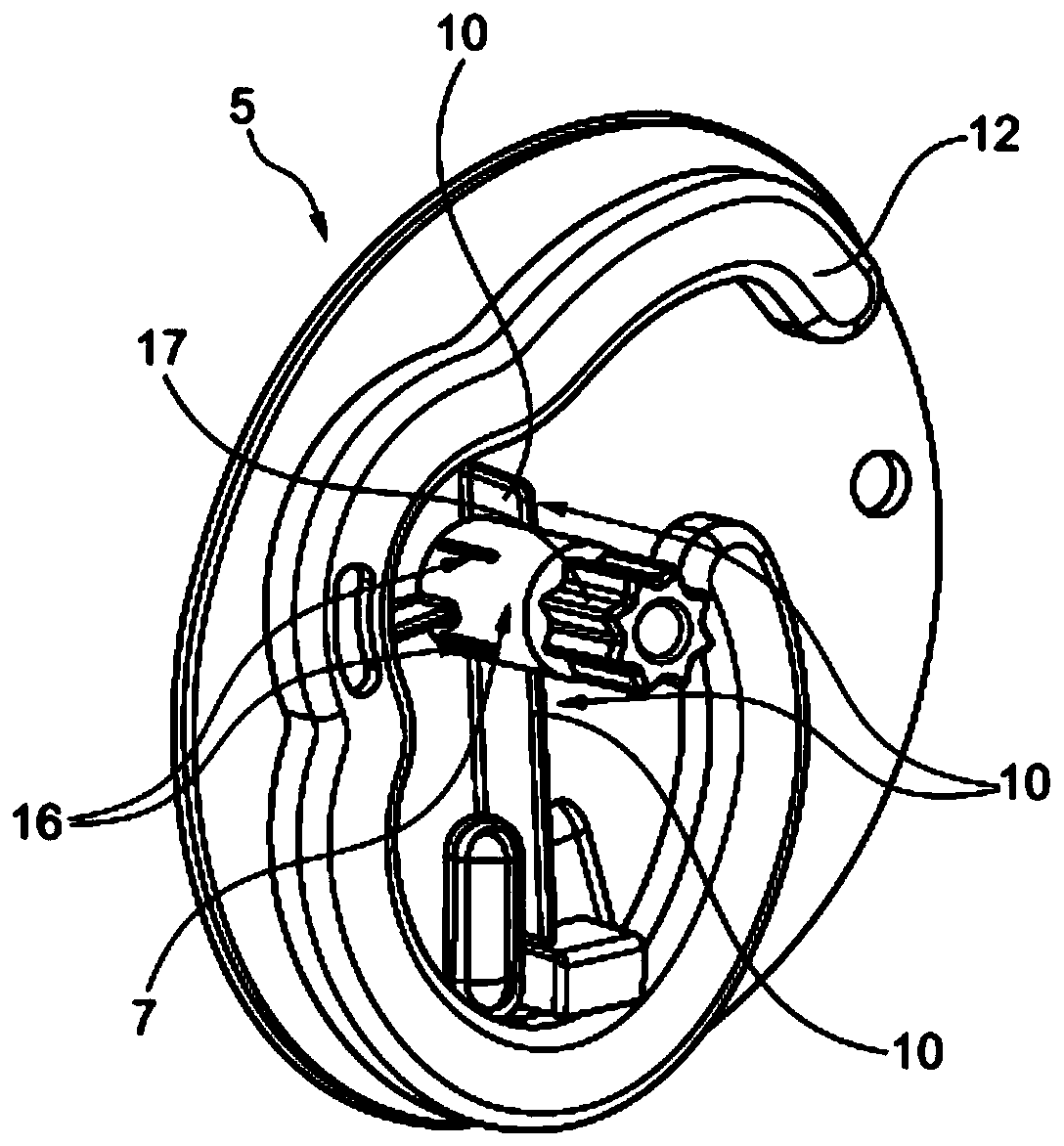

[0021] according to figure 1 , the moving assembly 1 of the air conditioning system 2 for a motor vehicle 3 according to the invention (which is not shown in further detail) has a control lever 4 for driving, in particular a damper (not shown), a cam disc 5 and a bearing plate 6 . The cam disc 5 here has bearing pins 7 (see also figure 2 ), while the bearing plate 6 has a bearing opening 8 in which the cam disc 5 is mounted in a torque-resistant manner by means of its bearing pin 7 in the mounting position and is rotatably mounted in the operating position. According to the invention, at least one groove 9, here two grooves 9, is provided at the bearing opening 8, wherein at least one tongue 10 formed in a complementary manner to the groove 9 is arranged on the bearing pin 7 of the cam disc 5, It is two tongues 10 in the text. In the predefined mounting position, the cam disc 5 is in this context with its tongue 10 (ie tongues 10 in the present case) entering into the asso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com