Medium-deep hole multi-stope and subsection common orepass mining method for mining hanging ore body

A mining method and a technology for hanging mines, which are applied in the field of medium-deep hole multi-stope and segmented co-slip mining, can solve the problems of prolonged infrastructure construction time and high cost of development systems, reduce cutting costs and improve mining efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

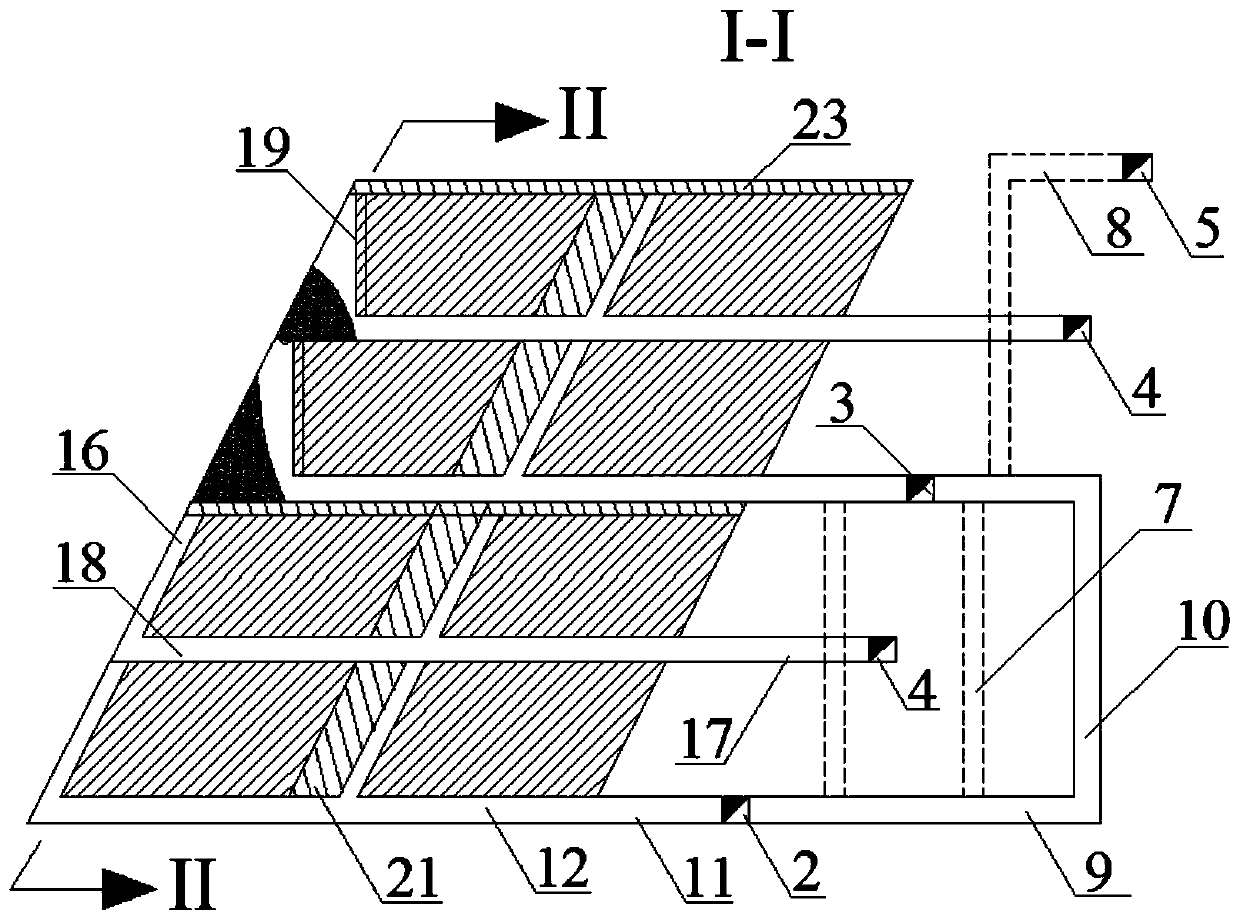

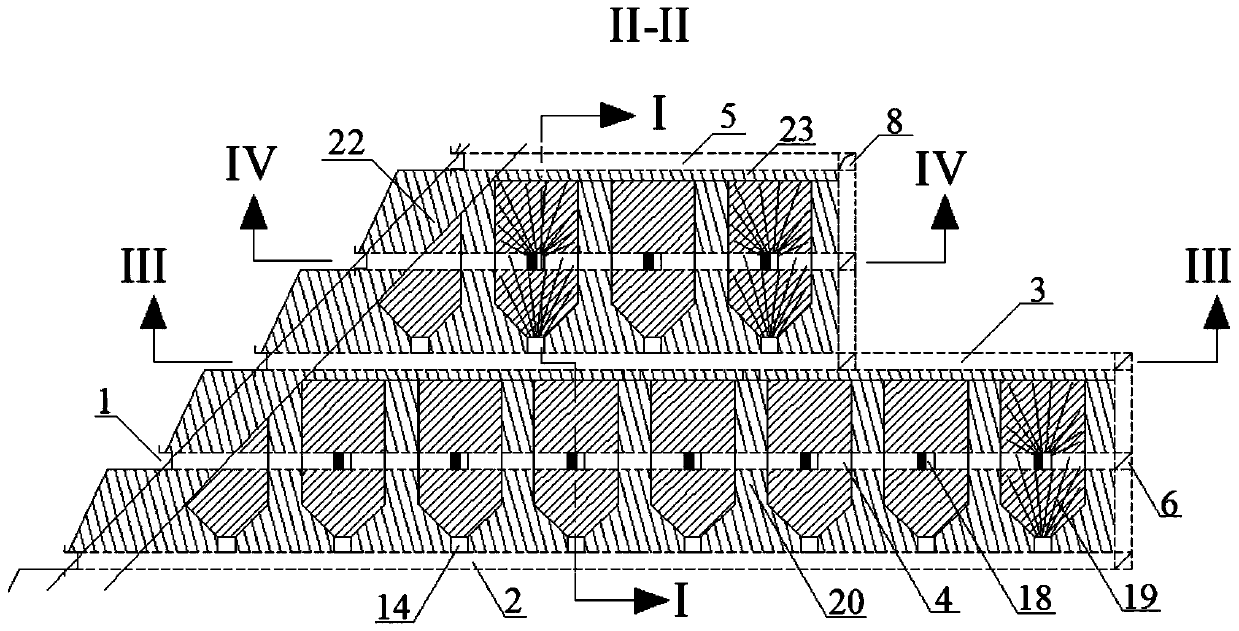

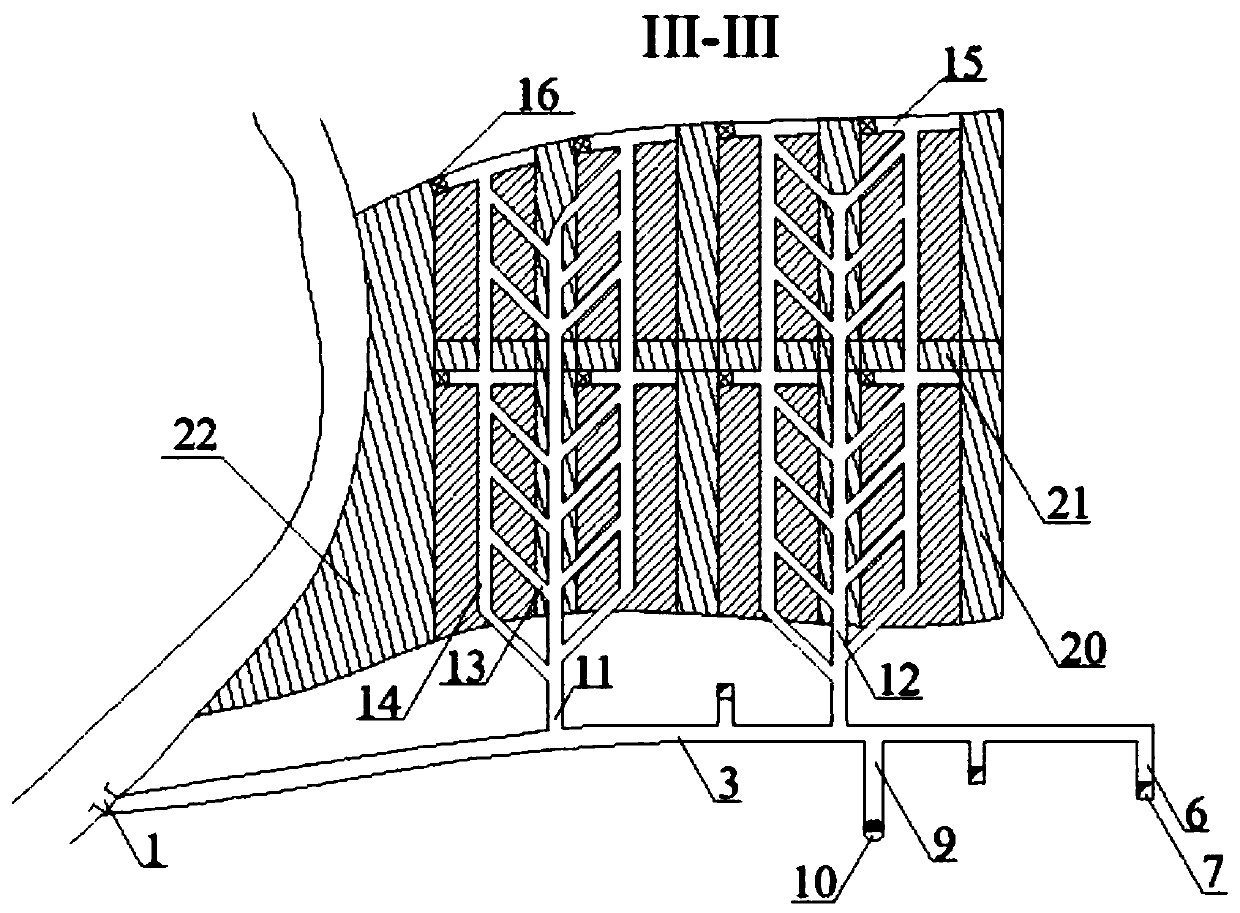

[0028] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0029] Such as Figure 1 to Figure 4 As shown, the medium-deep hole multi-stope mining method of the present invention for hanging side ore body mining and subsection total slip shaft mining method comprises the following steps:

[0030] (1) Carry out stage division to hanging wall ore body, medium-thick ore body ore block is arranged along the strike, thick ore body ore block is arranged vertically, according to the height of the open-pit step in the ore block is divided into sections, and horizontal intercolumns 20, 20, Longitudinal intercolumn 21 and side slope security ore pillar 22, the stage height is 48m, the length of ore block is 50m, the width of ore block is 20m, the height of rock drilling section is 24m, the width of longitudinal intercolumn 21 is 6m, and the width of transverse intercolumn 20 is 8m, and the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com