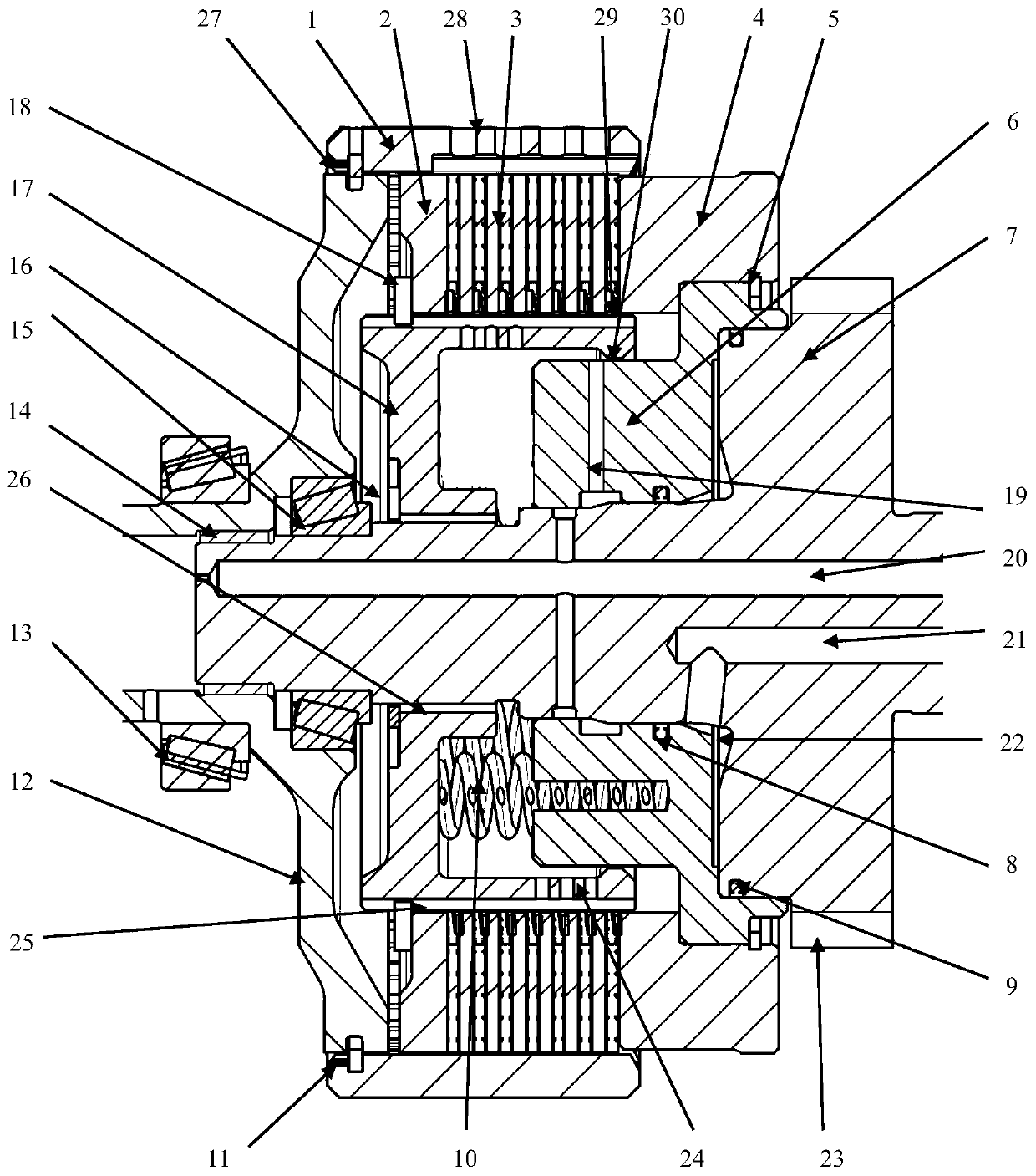

Clutch integrated structure and use method thereof

A technology for clutches and power take-offs, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of inability to ensure complete synchronization of on-off, large drag loss, complex structure, etc., and achieve compact structure design and reduced drag Loss, moving smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0031] The power take-off clutch integrated structure of the present invention controls the connection and disconnection between the engine power and the power take-off, and has a compact structure. The clutch structure integrates input gear hub, ring gear, clutch, clutch support, piston, power take-off input shaft and other parts. When the power is transmitted from the engine to the input gear hub, the working oil circuit is filled with high-pressure oil and reaches the piston cavity, pushing the piston to compress the clutch. Thereby the power is transmitted to the input gear on the input shaft of the power take-off for power transmission.

[0032] When the high-pressure oil pushes the piston to move, the lubricating oil circuit of the clutch is opened, and the lubricating oil reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com