Actuating device for friction clutch

A friction clutch and operating device technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as the influence of drag torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

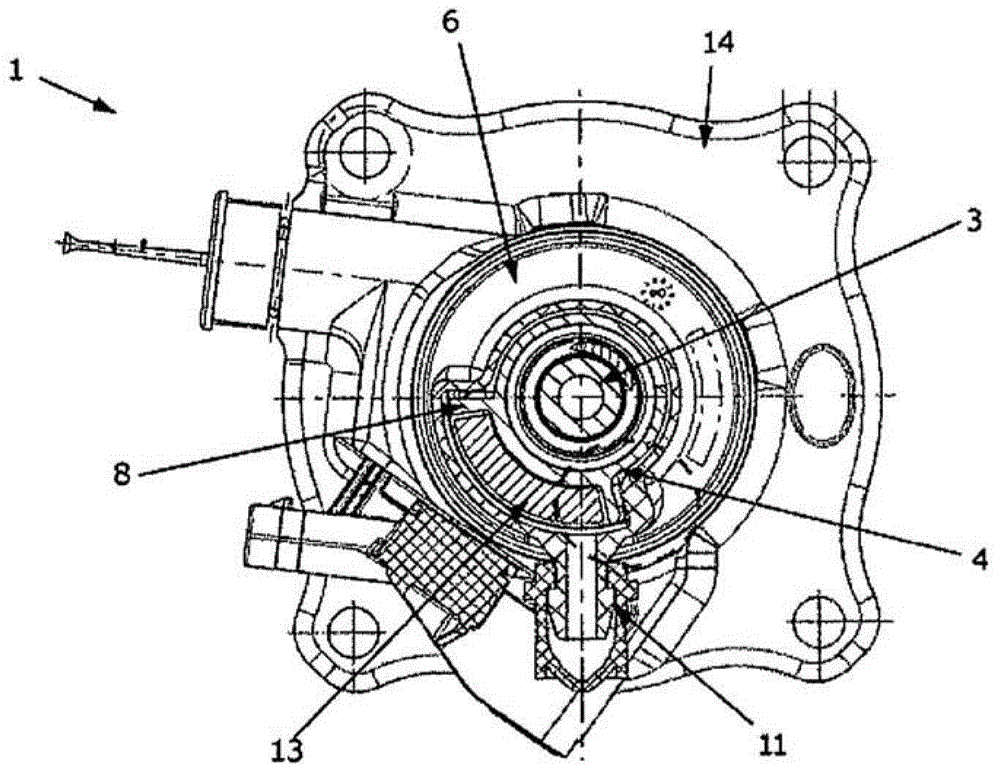

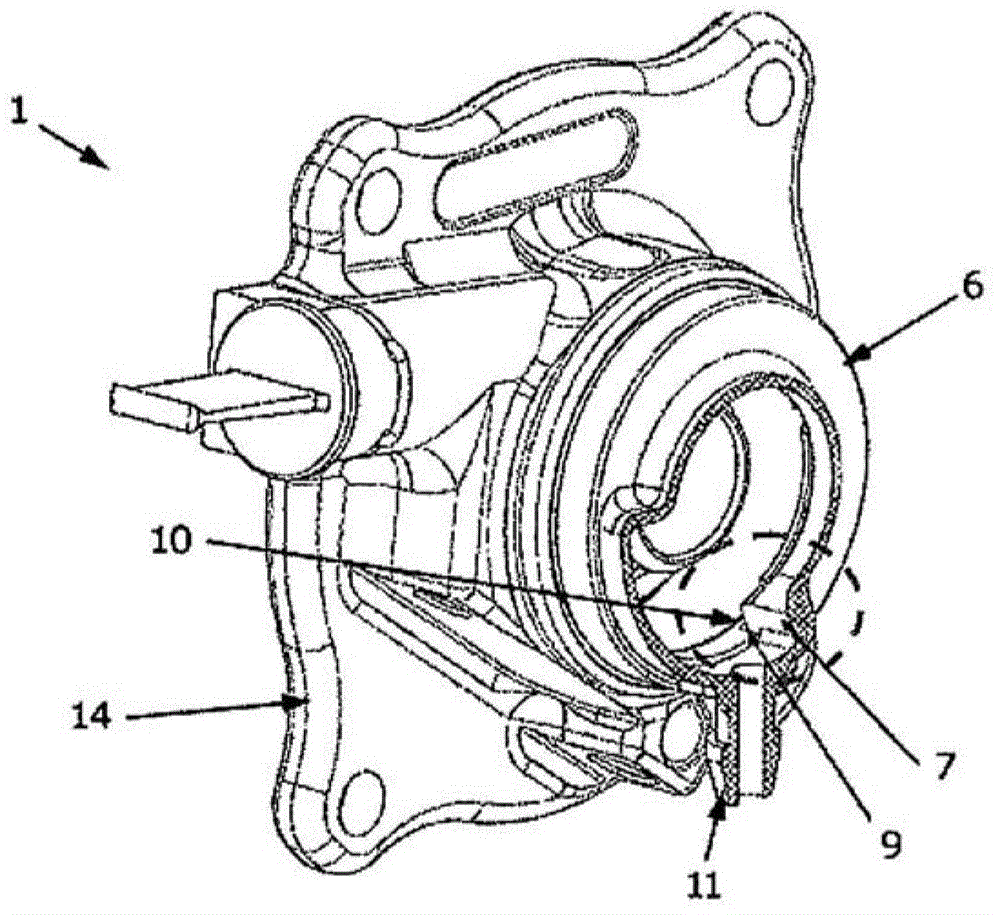

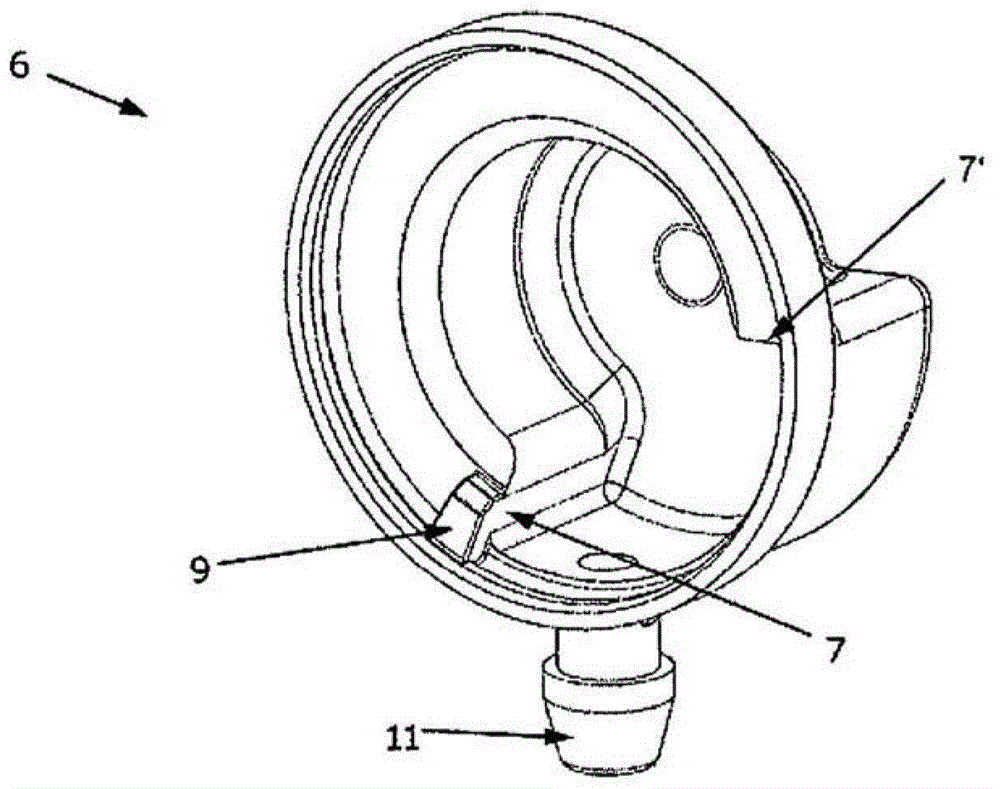

[0026] exist figure 1 A schematic sectional view of the manipulating device 1 according to the invention is shown in . The actuating device 1 has a housing 14 in which a central engagement part 4 is arranged on the piston 3 . In the lower left region, the central joint part 4 has a camber 8 which extends approximately over a quarter of the circumference of the central joint part 4 . A magnet 13 is arranged in the camber 8 . The central joint part 4 is covered by a cover 6 . In the illustrated embodiment of the handling device 1 , the cover 6 is partially shown in section, so that the shape and position of the central joint 4 can be seen. The cap 6 has a connection 11 at the lower end. The connection 11 is designed as a cylindrical through connection socket. In the embodiment shown, the connection 11 is closed by a closure.

[0027] The cover 6 is made of plastic, for example. The central joint part 4 is made of aluminum, for example. When the clutch is open or closed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com