Multi-disc brake

A technology of brakes and actuators, which is applied in the field of the invention, can solve the problems such as the inability to realize cooling fluid flow delivery, and achieve the effects of saving structural space, reducing drag loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

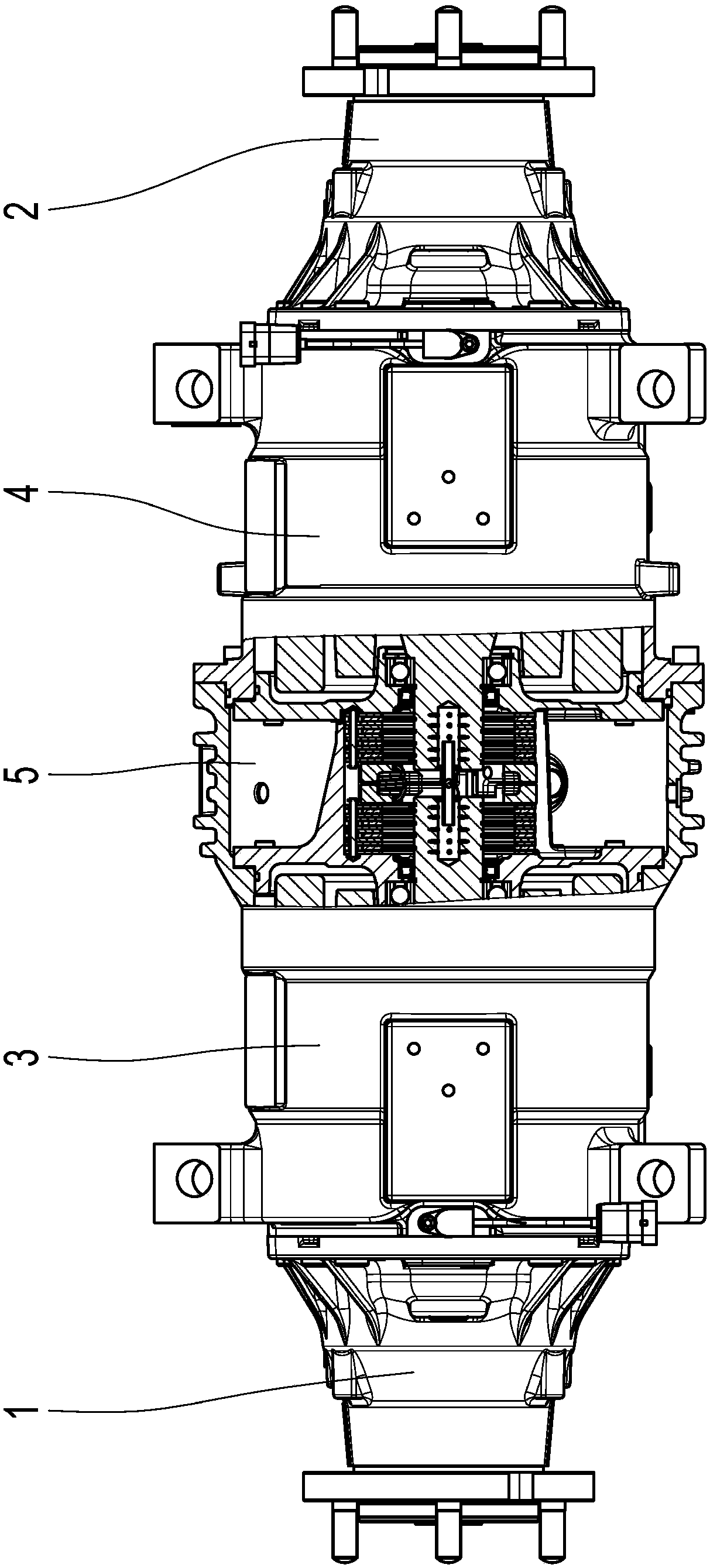

[0026] figure 1 An electric drive mechanism for a forklift is shown. The drive mechanism consists of a transmission 1 on the left, a transmission 2 on the right, an electric motor 3 on the left, an electric motor 4 on the right and a multi-disc brake 5 .

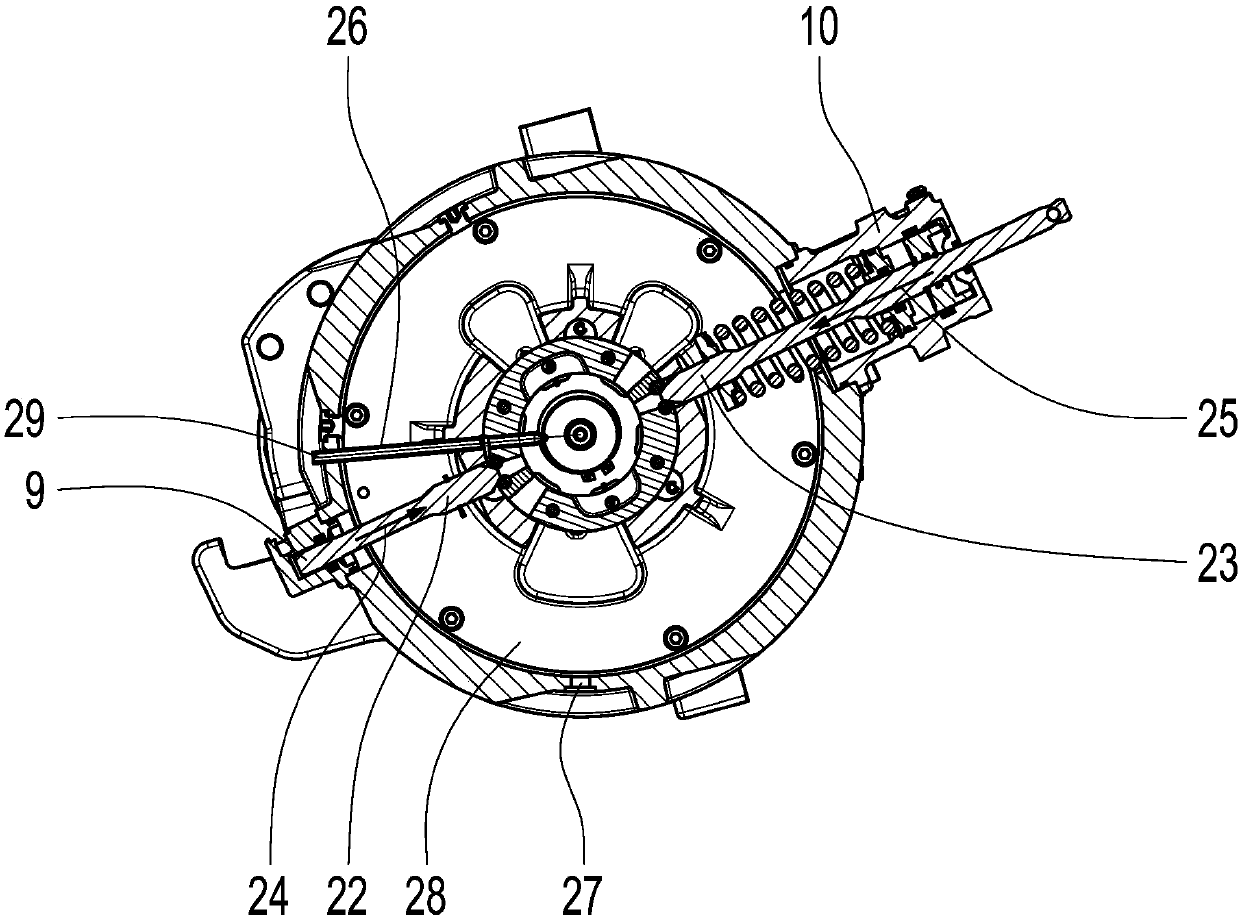

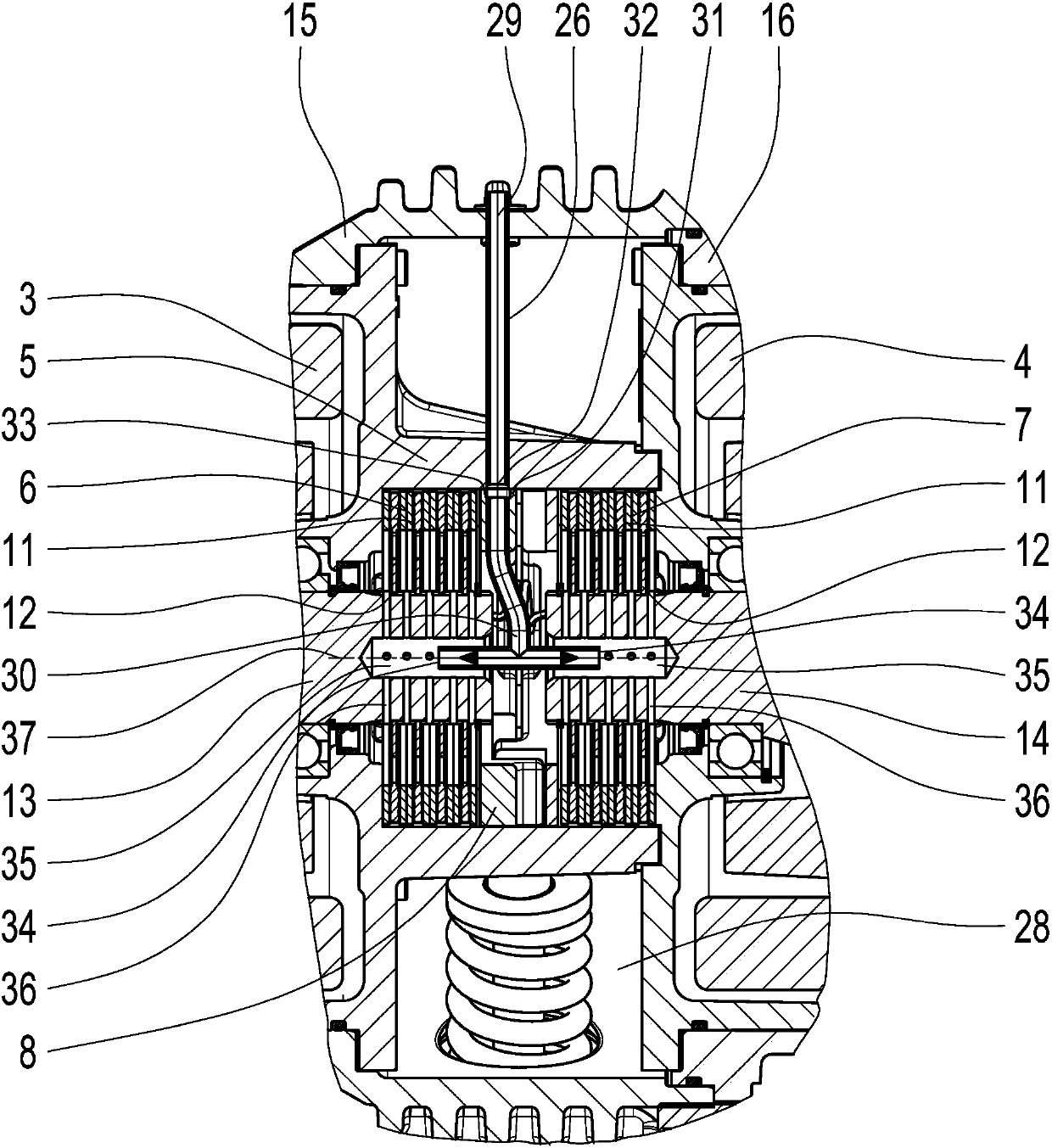

[0027] figure 2 and image 3 A multi-disc brake 5 and its structural environment are shown. The housing of the left transmission 1 is connected to the housing 15 of the left electric motor 3 . The housing of the right transmission 2 is connected to the housing 16 of the right electric motor 4 . The housings 15 and 16 of the electric motors 3 and 4 are fixedly connected to one another on the sides facing away from the transmission 1 and 2 respectively. Housing 15 of electric motor 3 on the left accommodates multi-disc brake 5 . The multi-disc brake 5 itself consists of a first disk pack assembly 6 , a second disk pack assembly 7 , a ball ramp actuator 8 , a positively acting actuating part 9 and a negatively acting act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com