Reinforcing method of pipe joint when suspending socket type pipe

A socket-type, pipe joint technology, applied in the direction of pipes/pipe joints/pipe fittings, non-removable pipe connections, pipe laying and maintenance, etc. The pipeline cannot transport the medium and other problems, so as to achieve the effect of low cost, simple construction and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

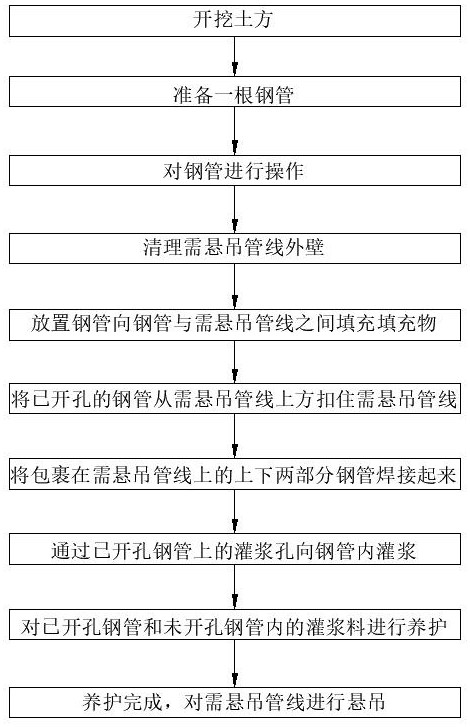

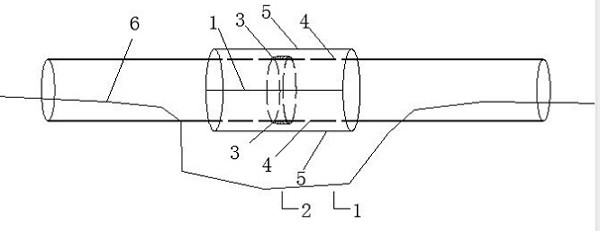

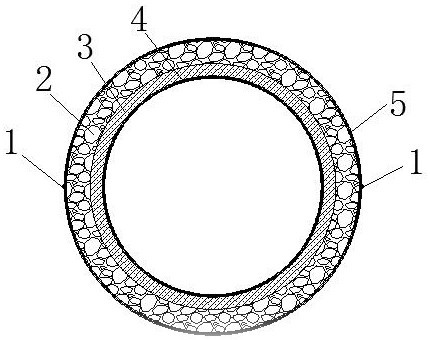

[0033] Embodiment 1, the pipe joint 3 reinforcement method when suspending socket-type pipes, such as Figure 1~4 As shown, this reinforcement method is aimed at the suspension of socket pipelines with pipe diameters from DN100 to DN600. This method can realize the reinforcement of pipe joint 3 when suspending socket-type pipes without damaging the original pipeline.

[0034] The reinforcement method comprises the following steps in turn:

[0035] 1) Excavate the earthwork to form the excavation line 6, so that the 3 joints of the pipeline that need to be suspended are exposed, and at the same time, an operation space of 100~500 mm is reserved below the 3 joints of the pipeline that need to be suspended; The upper half of the suspended pipeline is exposed. At the 3 joints of the pipeline to be suspended, the pipes within the range of 2~3 times the diameter and length of the pipeline to be suspended are completely exposed at the 3 joints of the pipeline to be suspended. An ope...

Embodiment 2

[0063] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the diameter of the pipeline to be suspended is DN 125, and the inner diameter of the pipeline to be suspended is 141.3 mm, so the diameter of the steel pipe is at least DN 150, and the diameter of the steel pipe is DN 125. The inner diameter is 168.3 mm.

Embodiment 3

[0064] Embodiment 3. The difference between this embodiment and Embodiment 1 is that the diameter of the pipeline to be suspended is DN 300, the inner diameter of the pipeline to be suspended is 323.8 mm, the diameter of the steel pipe is at least DN 350, and the inner diameter of the steel pipe is DN 300. It is 355.6 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com