Correction method of high-altitude propeller wind tunnel test data for the influence of tip Mach number

A propeller and Mach number technology, which is applied in the field of high-altitude propeller wind tunnel test data correction, can solve problems such as inconsistent balance errors, long installation and debugging time, and large differences in propeller scale model tension and torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

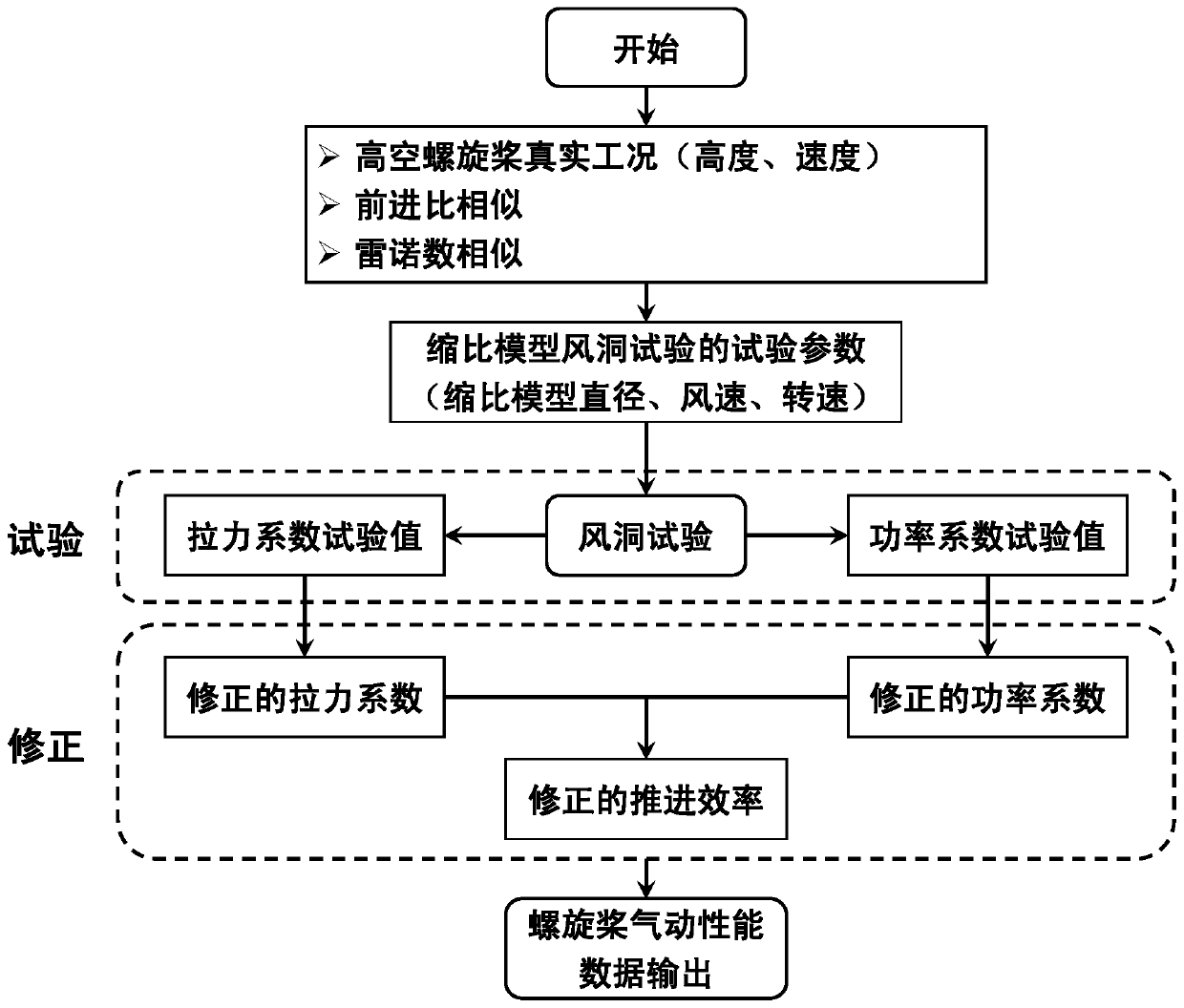

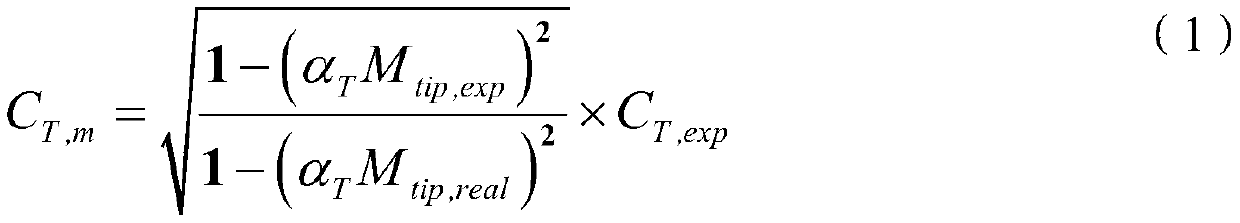

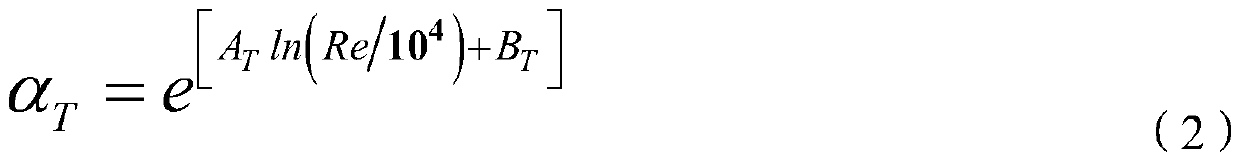

[0040] The technical problem to be solved by the present invention is to propose a high-altitude propeller wind tunnel test data correction method for the influence of tip Mach number, wherein the meaning of high-altitude in the present invention specifically refers to the high-altitude category. The invention corrects the wind tunnel test data obtained under the conditions of equal advance ratio and equal Reynolds number, and obtains performance data such as propeller pull coefficient, power coefficient and propulsion efficiency closer to the real working condition of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com