Electromechanical test device

A technology of electromechanical devices and centrifuges, which is applied in the field of electromechanical manufacturing, can solve problems such as low efficiency, mismatching, material waste and loss, and achieve the effects of flexible and convenient use, time saving, and convenient equipment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

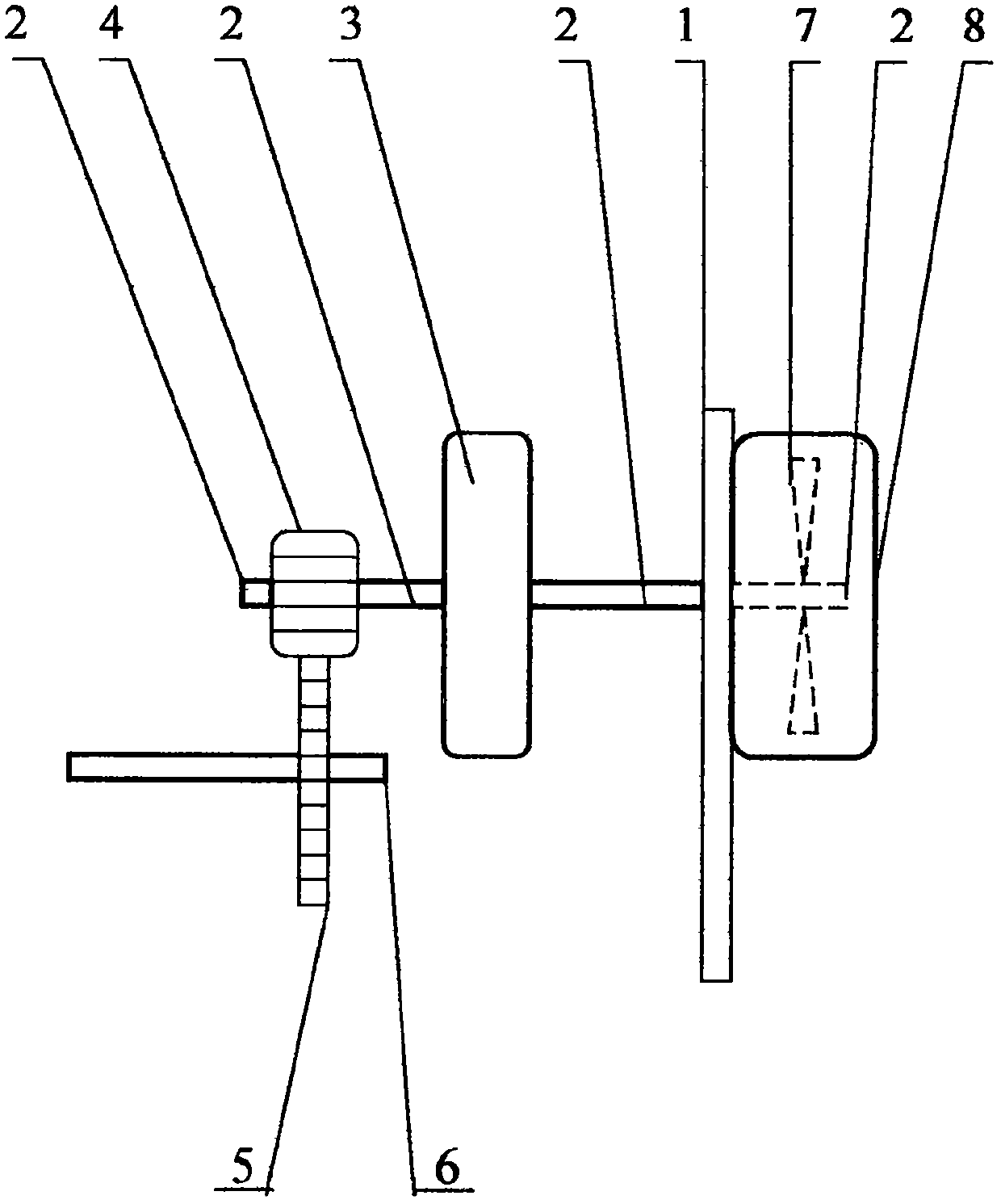

[0014] see figure 1 , in the embodiment, it is provided with the connecting shaft 2 on the housing 1, the connecting shaft 2 is connected to the electromechanical device 3, one end of the connecting shaft 2 is connected to the pinion gear device 4, and the pinion gear device 4 is a transmission device or a ratchet wheel, Pinion device 4 engages bull gear 5, bull gear center has axle 6, and when connecting shaft 2 rotates bull gear 5, axle 6 rotates thereupon, and the diameter of bull gear 5 is more than 1.5 times of pinion gear 4 diameters, in order to according to According to the needs of different environments, the connecting shaft 2 or the electromechanical device 3 can be arranged in two types, and one of them can be selected: the rotating part of the connecting shaft 2 or the electromechanical device 3 is provided with a magnetic rotating impeller 7 or a magnetic substance; the connecting shaft 2 Or the electromechanical device 3 is not provided with a magnetic rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com