A road condition simulation loading test device and test method for electric vehicle drive motor

A loading test device and road condition simulation technology, which is applied in the direction of motor generator testing, etc., can solve the problems of single test model, inability to simulate complex road conditions, and inaccurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

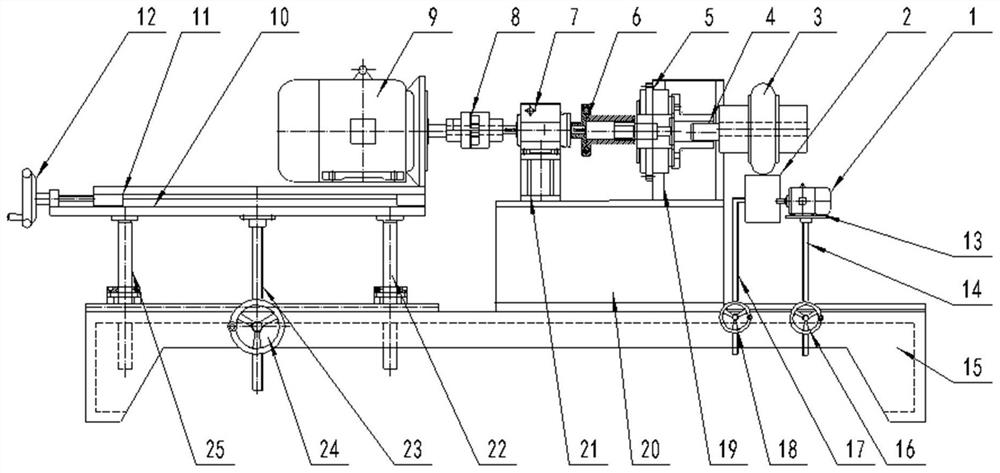

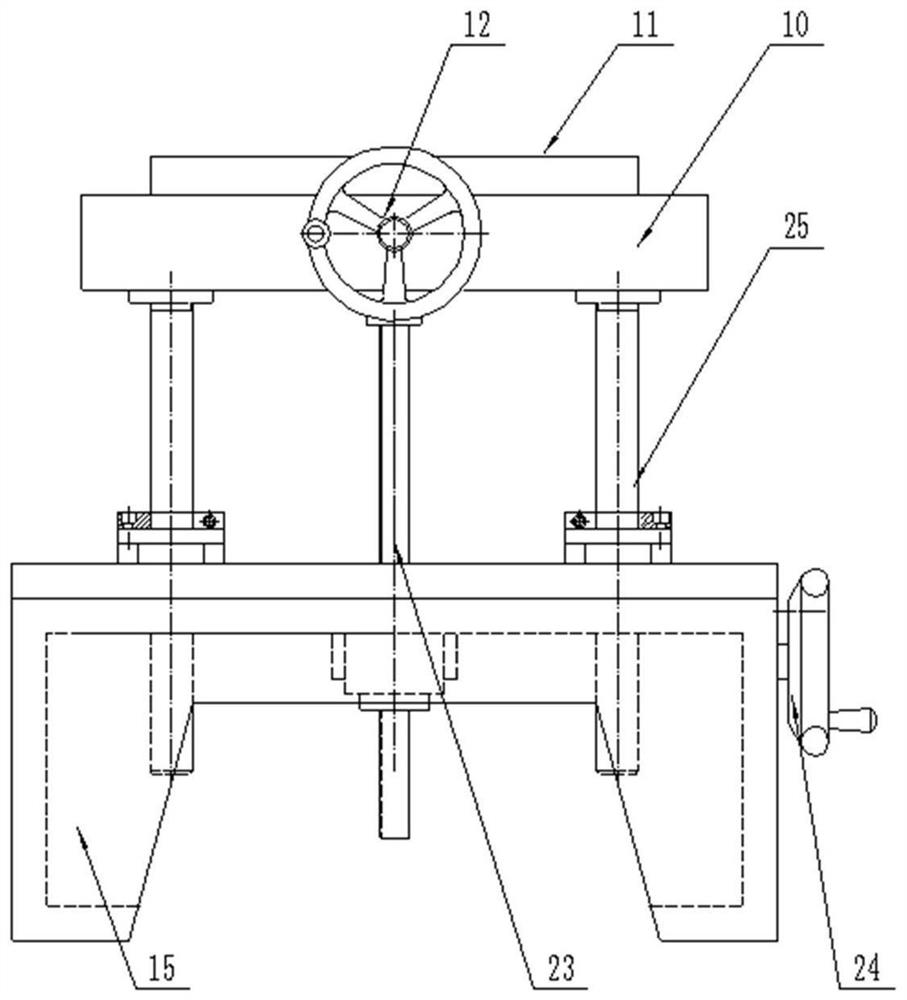

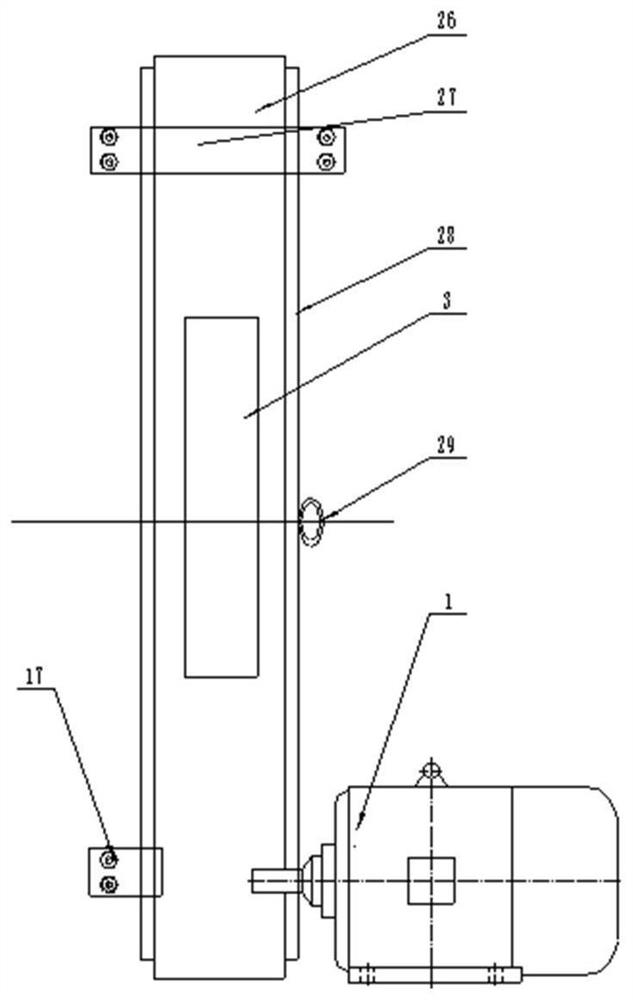

[0045] The test device of the present invention is composed of a motor drive controller at the motor end under test, a motor under test, a strain-type torque speed sensor, a reducer, a transmission device, vehicle tires, a power motor, a lifting device, and a detection control cabinet; the transmission device, The loading table composed of tires and power motors is used to more realistically simulate various road conditions to load the load motor; the motor lifting table adjusts the height of the motor to test different types of motors, improving test efficiency and applicability; the detection cabinet communicates with the CAN bus and the data acquisition module Communicate with the motor motion control module, adjust the road condition simulation loading platform according to different requirements to realize the realistic simulation of the road surface of the tested motor under different weather, different roughness and different driving modes; the test mainly simulates the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com