Automatic detection system for positioning of transformer body falling into a box and detection method thereof

An automatic detection, transformer technology, applied in radio wave measurement systems, inductance/transformer/magnet manufacturing, instruments, etc., can solve problems such as easy collision of fuel tanks, damage to the body, and visual injury of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

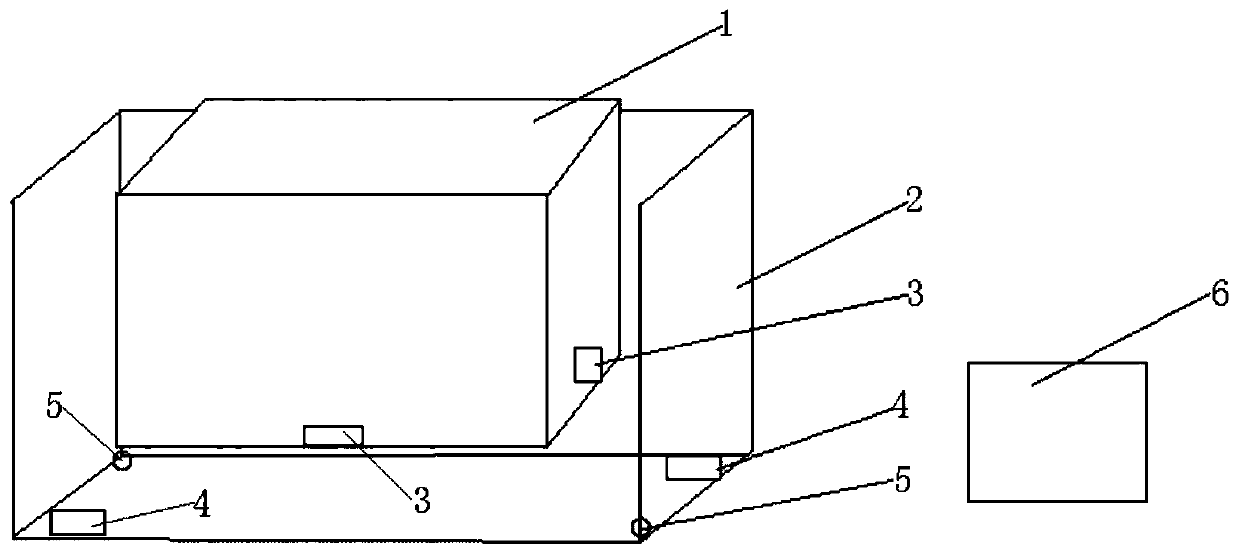

[0027] like figure 1 Shown is a schematic structural diagram of an embodiment of the present invention. An automatic detection system for the positioning of a transformer body falling into a box, comprising: four laser distance measuring sensors 3 arranged at the positions of the lower clips around the body 1, used to automatically monitor the distance between the clips and the tank wall of the oil tank 2 during the falling process of the body 1 The distance between the inner side and the lower part realizes real-time distance measurement; two wide-angle cameras 4 are arranged at two diagonal positions at the bottom of the fuel tank 2 for real-time video monitoring of the falling process of the body 1; The two safety light curtains 5 at the position are used to prompt early warning and alarm information in time; the display terminal installed in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com