Chemical safety live-action simulation drilling system based on VR technology

A technology for simulation drills and real scenes, applied in the field of chemical safety simulation drill systems, can solve problems such as inability to improve accident response capabilities, inability to create accident scenarios, and inattentiveness, and achieve the effect of improving emergency response capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

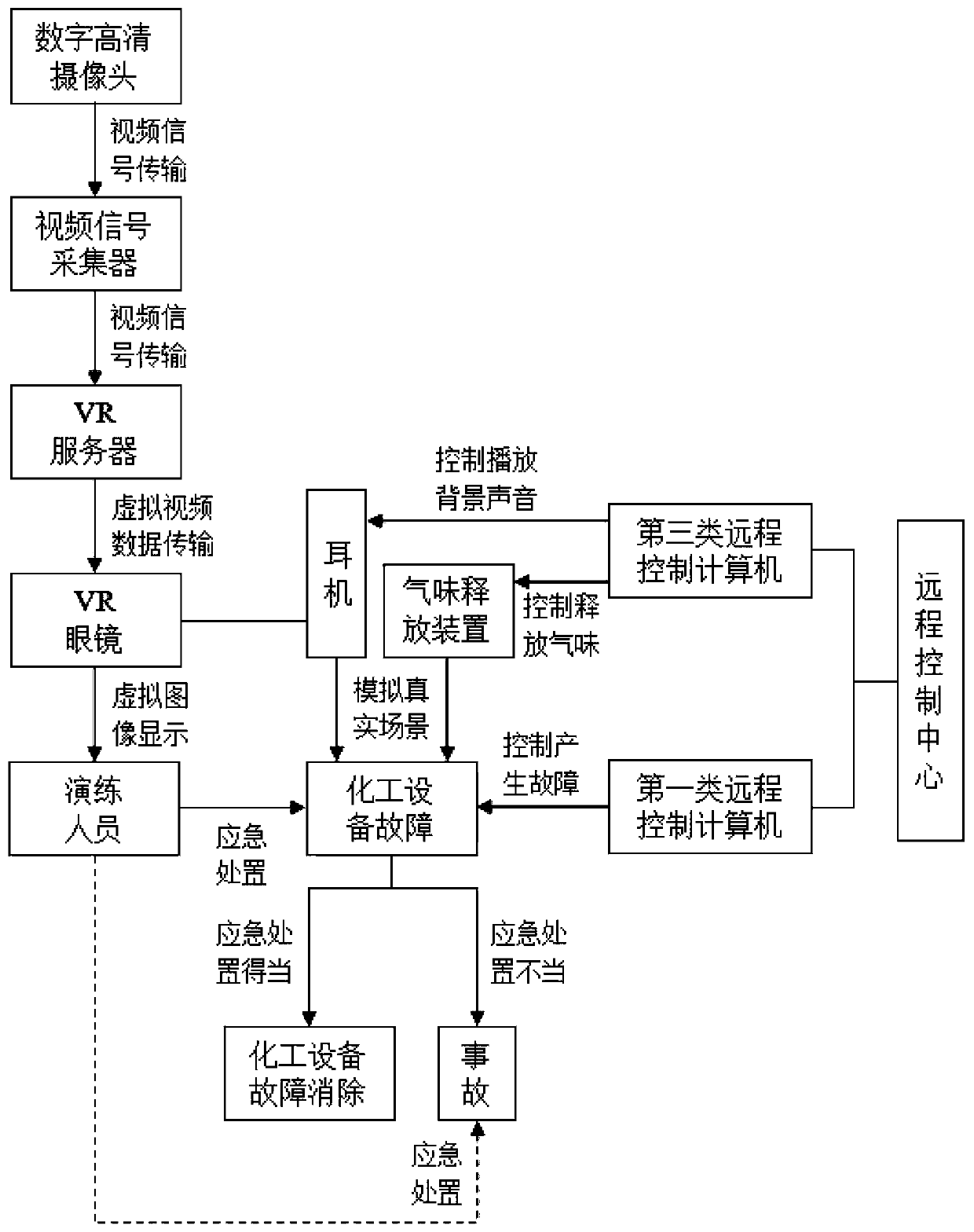

Embodiment 1

[0024] Embodiment 1: the present invention discloses a chemical industry safety simulation exercise system based on VR technology, including a digital high-definition camera, a signal collector, a VR server, VR glasses with earphones, an odor release device, and a remote control center; The signal collector receives the real-time video signal from the digital high-definition camera, and inputs the signal into the VR server; the VR server uses VR software to process the video signal, generates virtual video data and then enters it into the VR glasses to display; the remote control center controls When one or some chemical equipment in the real scene of the exercise fails, control the earphones that come with the VR glasses to play the background sound related to the equipment failure in the exercise, and control the odor release device to release the odor related to the equipment failure in the exercise; the present invention Specifically, it can be used for emergency response s...

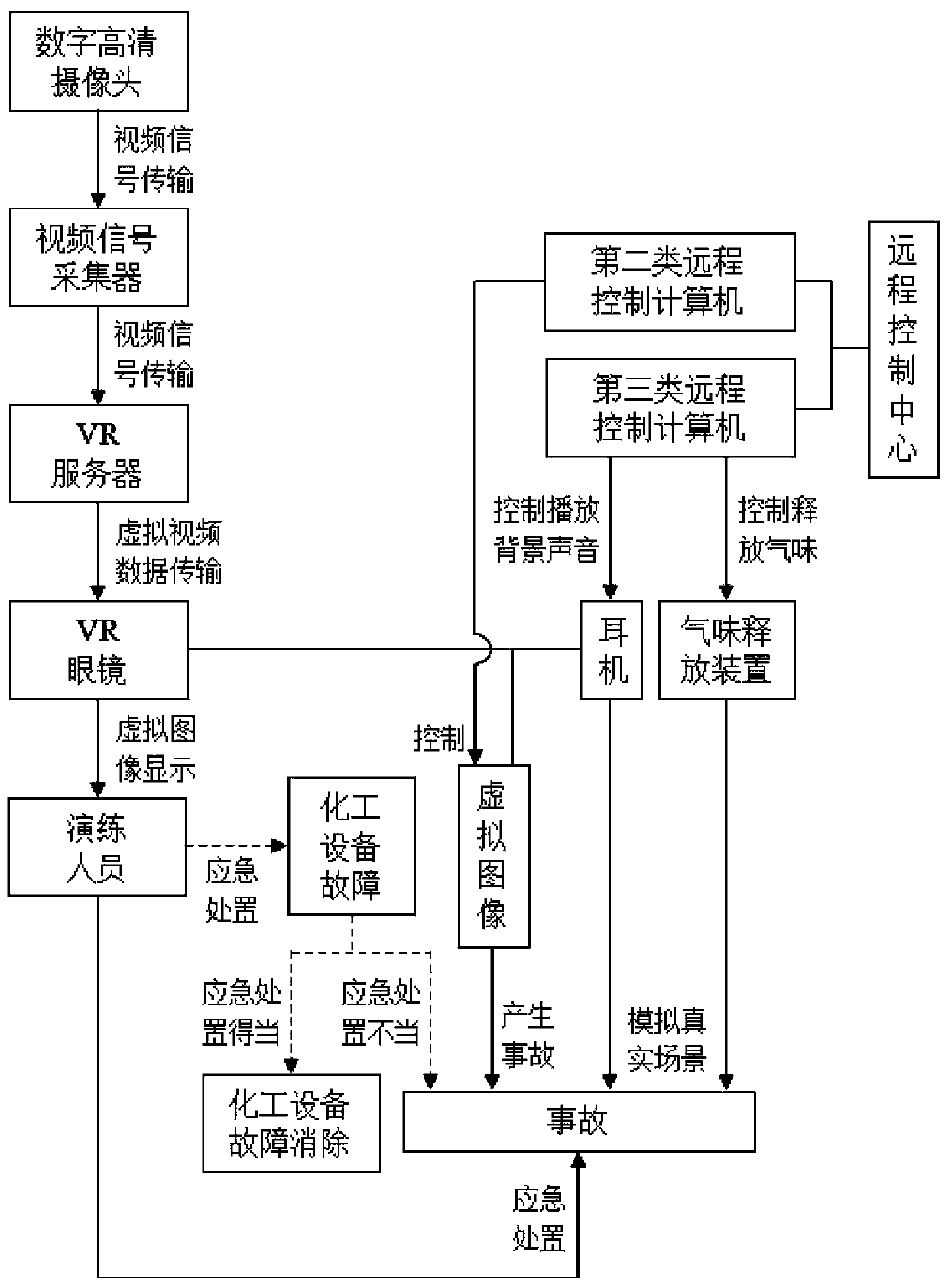

Embodiment 2

[0026] Embodiment 2: the present invention discloses a chemical industry safety simulation exercise system based on VR technology, including a digital high-definition camera, a signal collector, a VR server, VR glasses with earphones, an odor release device, and a remote control center; The signal collector receives the real-time video signal from the digital high-definition camera, and inputs the signal into the VR server; the VR server uses VR software to process the video signal, generates virtual video data and then enters it into the VR glasses to display; the remote control center controls Drill one or some chemical equipment failures in the real scene, control the virtual images displayed by the VR glasses to produce accidents caused by improper handling of the equipment failures, control the earphones that come with the VR glasses to play and drill equipment failures and accidents Relevant background sound, control the odor release device to release the odor related to ...

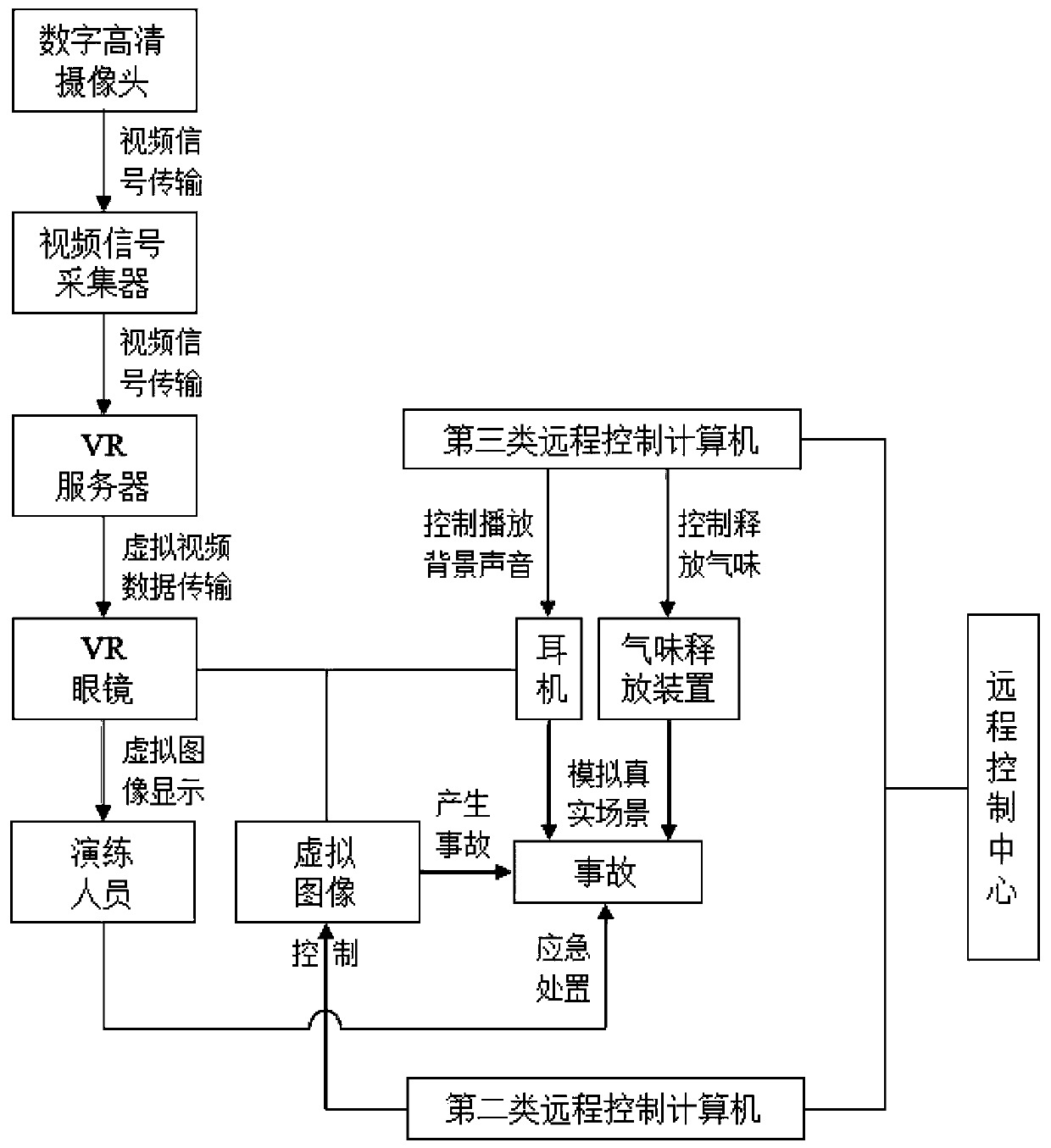

Embodiment 3

[0028]Embodiment 3: the present invention discloses a chemical industry safety simulation drill system based on VR technology, including a digital high-definition camera, a signal collector, a VR server, VR glasses with earphones, an odor release device, and a remote control center; The signal collector receives the real-time video signal from the digital high-definition camera, and inputs the signal into the VR server; the VR server uses VR software to process the video signal, generates virtual video data and then enters it into the VR glasses to display; the remote control center controls The virtual images displayed by the VR glasses produce accidents (the accidents do not include accidents caused by chemical equipment failures, but only general accidents caused by natural disasters or man-made fires, explosions, etc.), control the headphones that come with the VR glasses to play and The background sound related to the accident occurred in the drill, and the odor release de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com