Normally-closed reed switch

A reed switch, normally closed technology, applied in the field of reed switches, can solve the problems of easy to connect the normally open pins by mistake, failure of the reed switch, and inability to differ in magnetic field strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

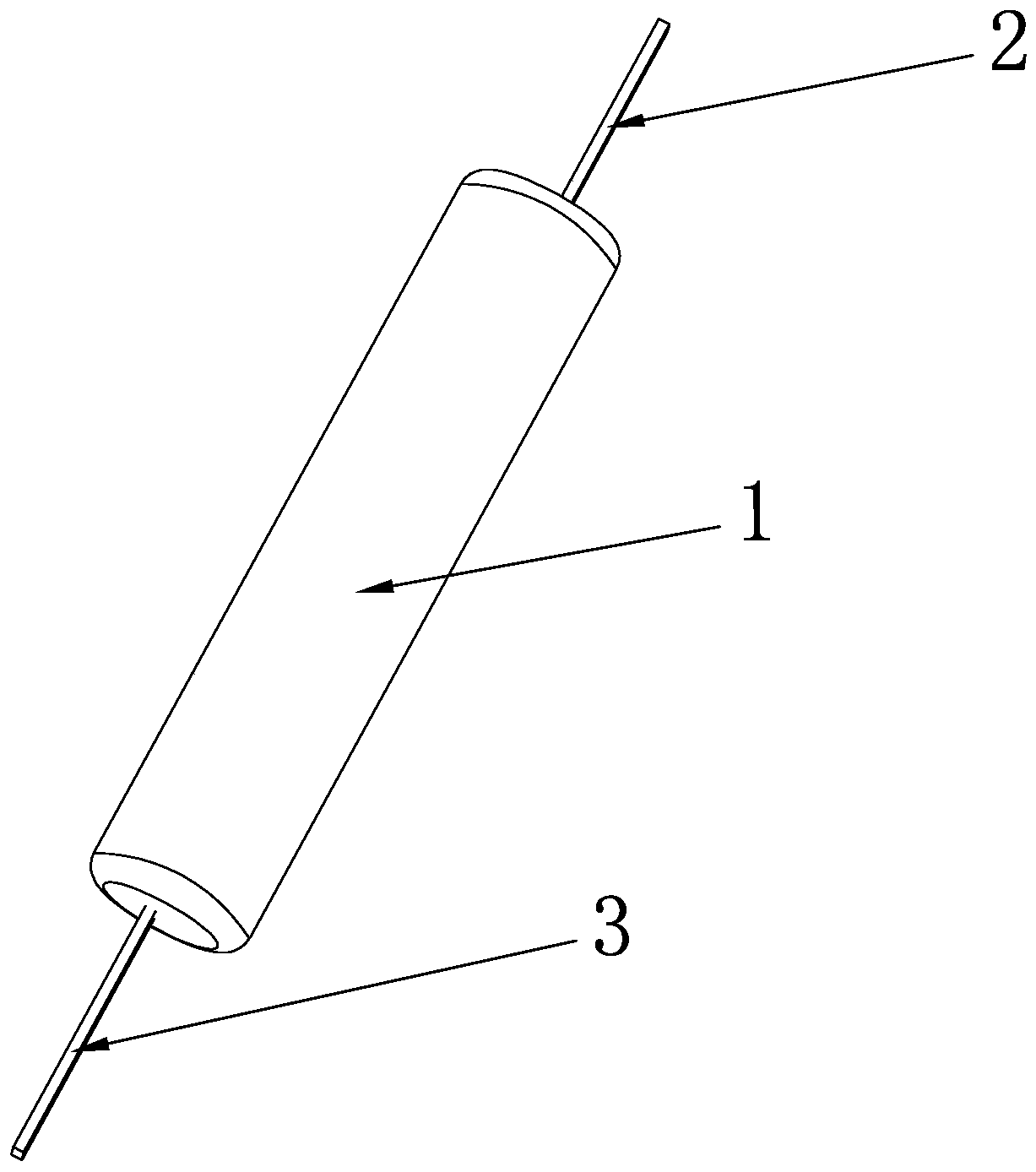

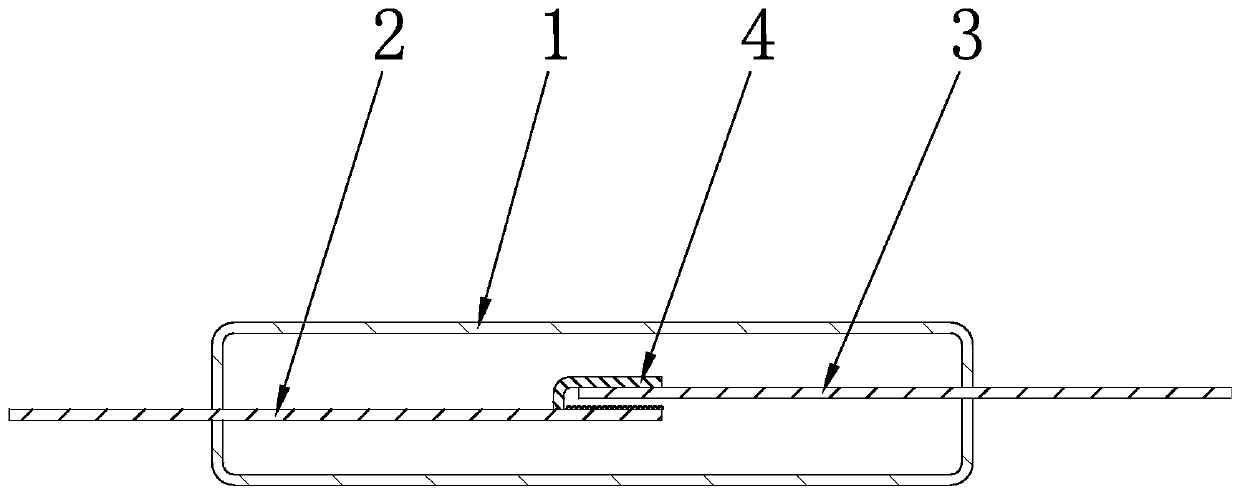

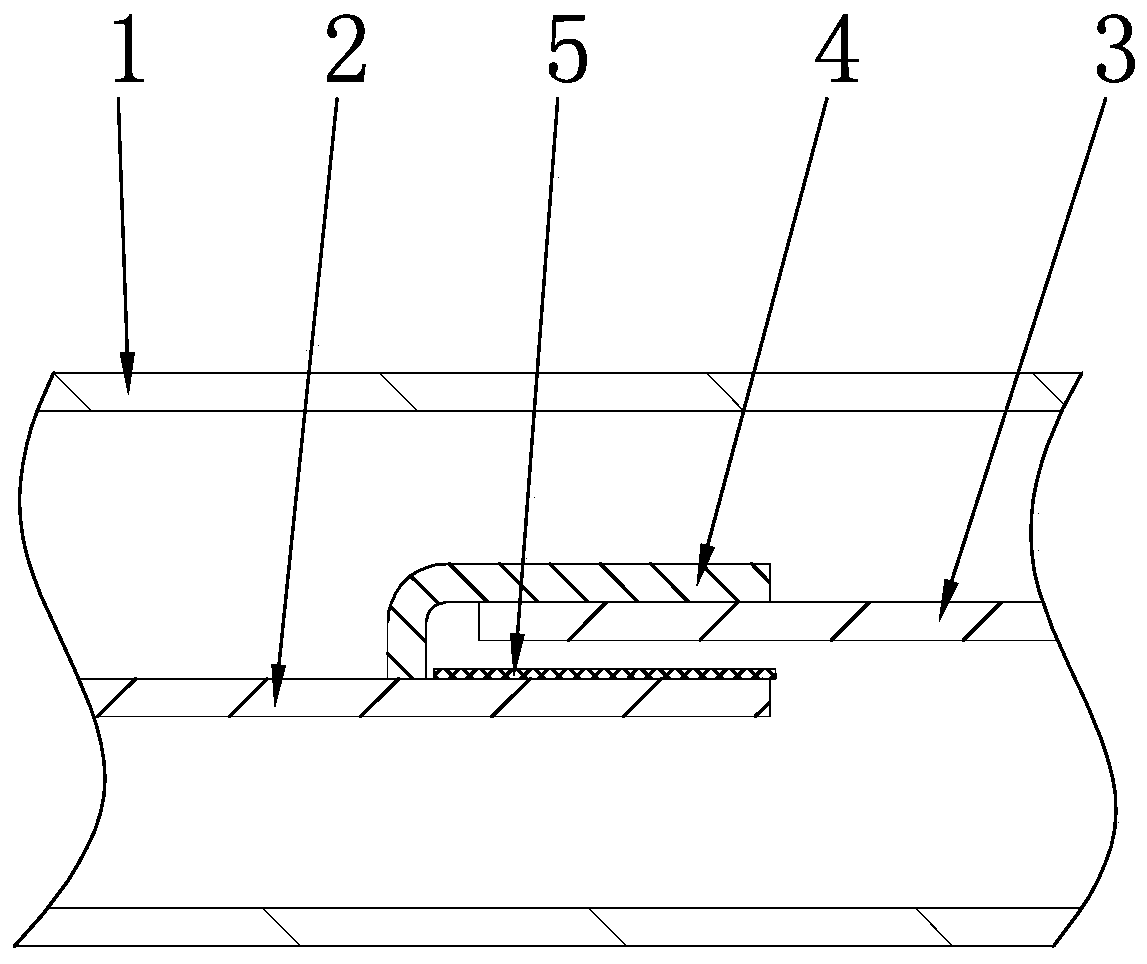

[0022] see Figure 1-Figure 4 , a kind of normally closed reed switch of the present invention comprises a tube body 1, and the tube body 1 is an insulating tube. In this embodiment, the tube body 1 is a glass tube; There are a first magnetically conductive shrapnel 2 and a second magnetically conductive shrapnel 3, one end of the first magnetically conductive shrapnel 2 and one end of the second magnetically conductive shrapnel 3 are sealed inside the tube body 1, and the tube body 1 is filled with The inert gas is used to protect the first magnetically conductive shrapnel 2 and the second magnetically conductive shrapnel 3 from being oxidized and corroded when arc sparks are generated when the circuit is turned on or off.

[0023] Further, the length direction of the first magnetic shrapnel 2 and the second magnetic shrapnel 3 are parallel to the length direction of the pipe body 1, and the first magnetic shrapnel 2 and the second magnetic shrapnel 3 are both electrically co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap