Aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and capacitor cores, applied in the field of capacitors, can solve the problems of increasing environmental pollution, wasting materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

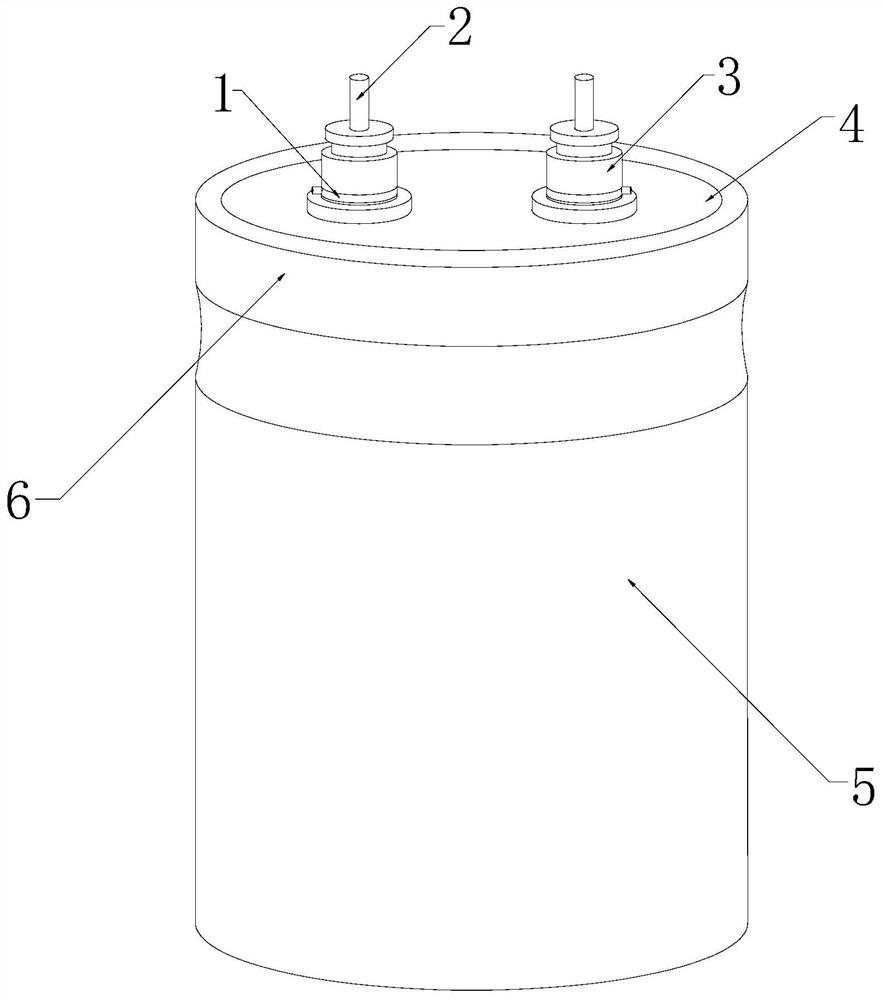

[0028] see Figure 1-Figure 6 , an aluminum electrolytic capacitor, its structure includes a rotating groove 1, a lead wire 2, an operator 3, an explosion-proof cover 4, a body 5, and a top cover 6, the rotating groove 1 and the operator 3 are an integrated structure, and the explosion-proof cover 4 is arranged above the body 5, the body 5 and the top cover 6 are fixedly connected, and the operator 3 is arranged on the body 5;

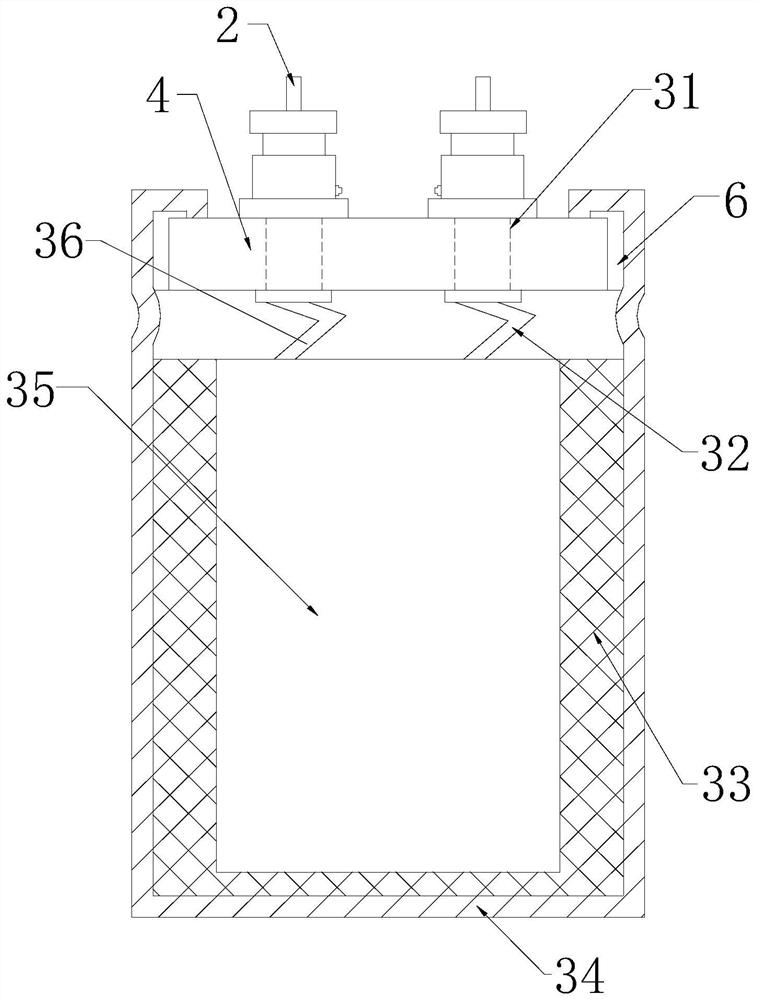

[0029] The manipulator 3 is provided with a regulator 31, a negative rod 32, a liquid chamber 33, a body 34, a capacitor core 35, and a positive rod 36. The regulator 31 is mechanically installed with the body 34, and the regulator 31 is two A negative electrode rod 32 and a positive electrode rod 36 are respectively installed below the side. The positive electrode rod 36 is provided with a capacitor core 35 , and a liquid chamber 33 is provided around the capacitor core 35 .

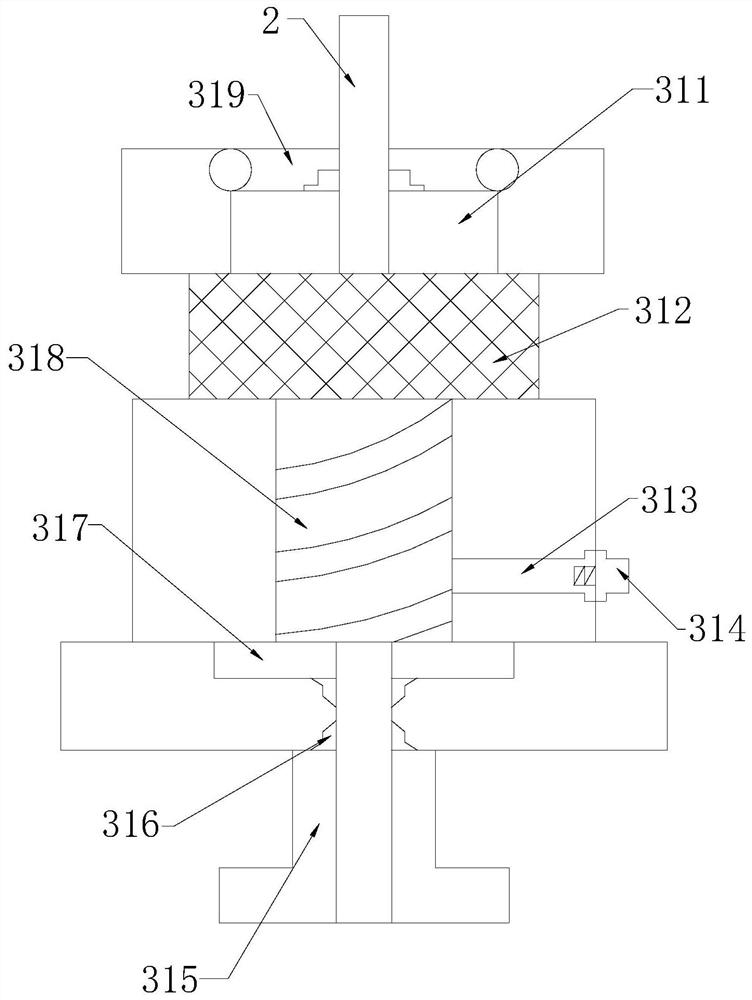

[0030] The regulator 31 is provided with a charging chamber 311, a rectifi...

Embodiment 2

[0037] see Figure 1-Figure 7 , an aluminum electrolytic capacitor, its structure includes a rotating groove 1, a lead wire 2, an operator 3, an explosion-proof cover 4, a body 5, and a top cover 6, the rotating groove 1 and the operator 3 are an integrated structure, and the explosion-proof cover 4 is arranged above the body 5, the body 5 and the top cover 6 are fixedly connected, and the operator 3 is arranged on the body 5;

[0038] The manipulator 3 is provided with a regulator 31, a negative rod 32, a liquid chamber 33, a body 34, a capacitor core 35, and a positive rod 36. The regulator 31 is mechanically installed with the body 34, and the regulator 31 is two A negative electrode rod 32 and a positive electrode rod 36 are respectively installed below the side. The positive electrode rod 36 is provided with a capacitor core 35 , and a liquid chamber 33 is provided around the capacitor core 35 .

[0039] The regulator 31 is provided with a charging chamber 311, a rectifi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap