Lateral-striped solid-oxide fuel cell

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve problems such as short circuits, and achieve the effect of stabilizing power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

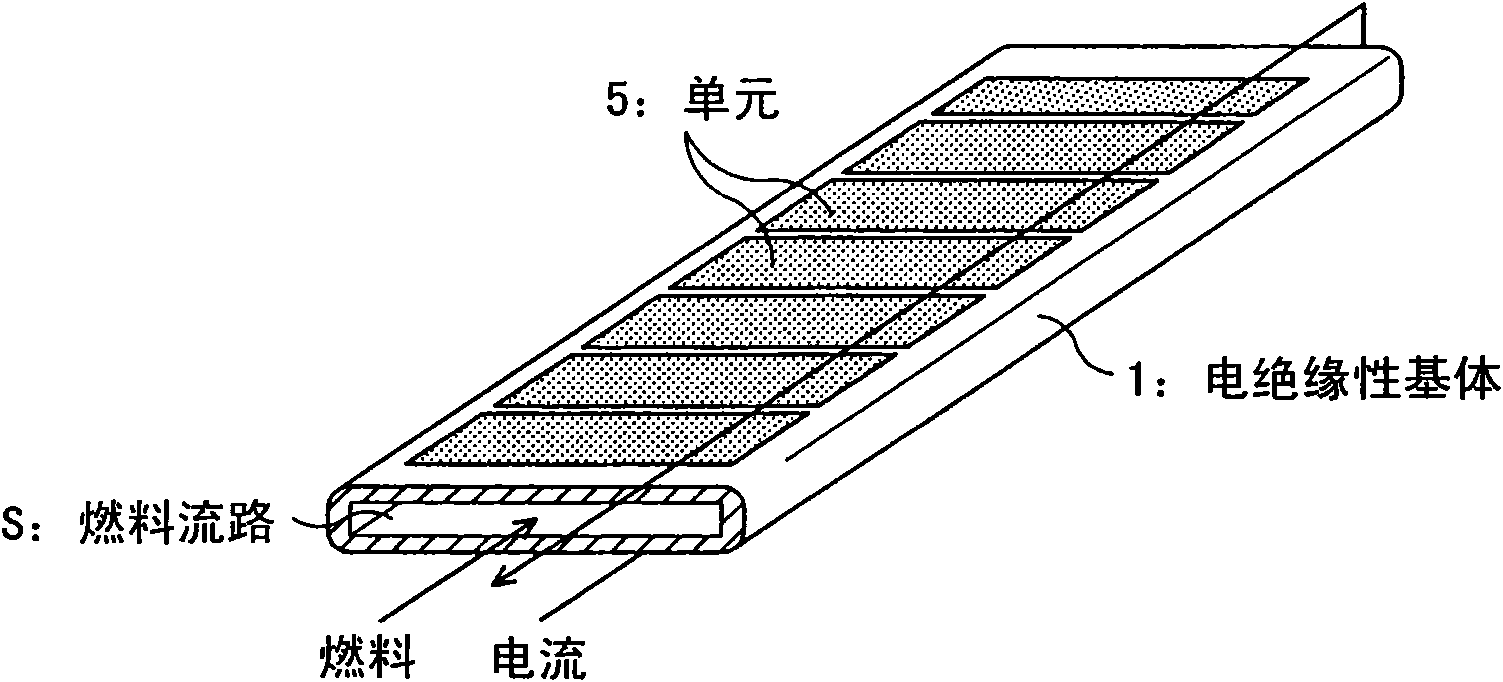

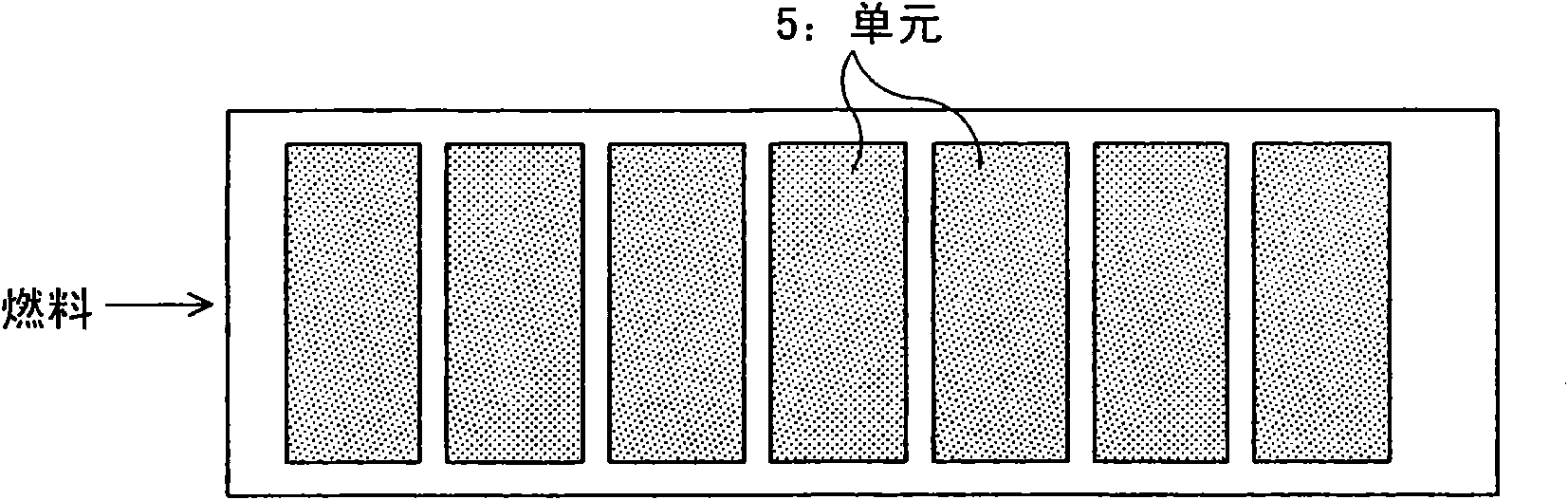

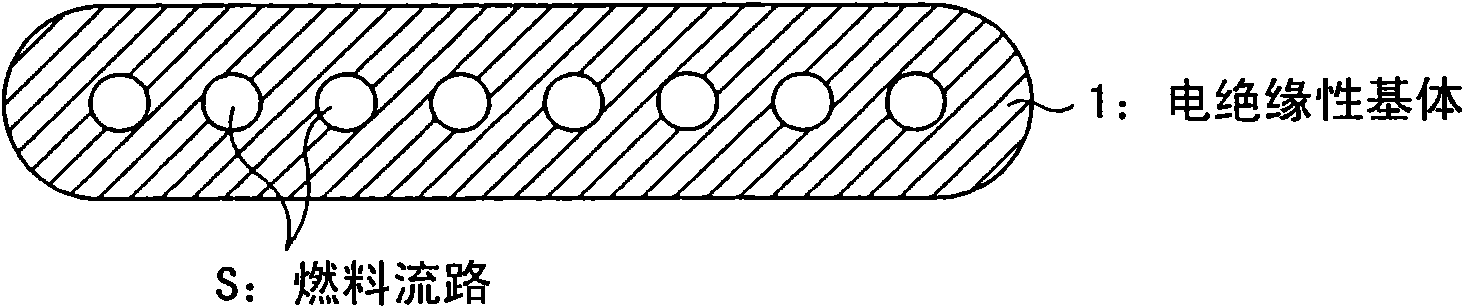

[0061] The horizontal stripe type solid oxide fuel cell of the present invention (1) to (4) includes a fuel flow path from the fuel supply port to the fuel discharge port inside, and has two front and rear sides parallel to the fuel flow path on the outside. A horizontal grained solid oxide fuel cell with a porous electrically insulating matrix on the left and right sides; the horizontal grained solid oxide fuel cell of the present invention (5) to (8) is comprised of The air flow path from the air supply port to the air discharge port, and the horizontal grain type solid oxide fuel having a porous electrically insulating substrate on the front and back surfaces and the left and right sides parallel to the air flow path on the outside Battery.

[0062] Next, groups (1) to (4) of the present invention and groups (5) to (8) of the present invention will be described in order. The common matters of the two groups are mainly described in the parts of groups (1) to (4) of the pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap