Power output circuit, LED drive circuit, drive method and LED

A technology of LED drive and power output, applied in the field of electronics, can solve problems such as increased cost, poor power consistency, design limitations, etc., to achieve the effect of solving interference, high reliability, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

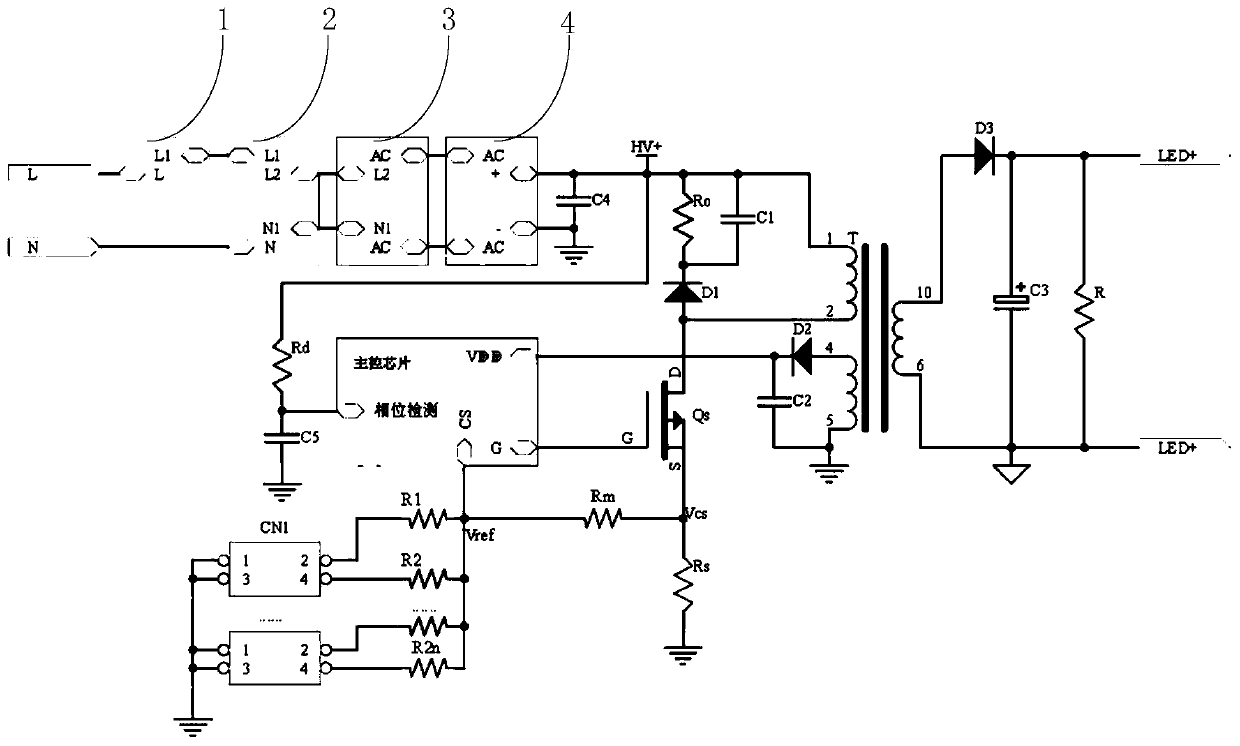

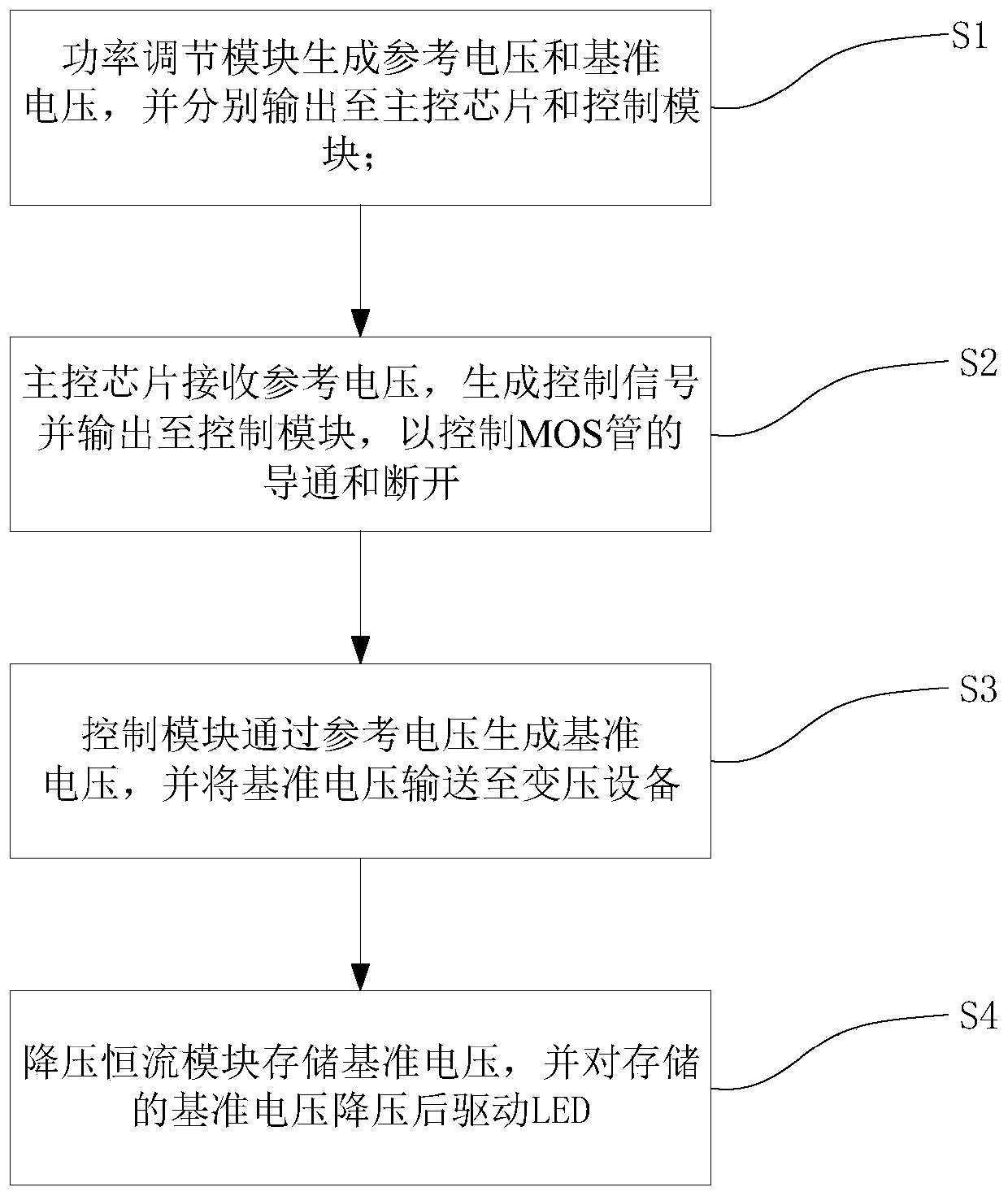

[0035] refer to figure 1 , Embodiment 1 provides a power output circuit, the power output circuit includes a main control chip, a power adjustment module and a control module.

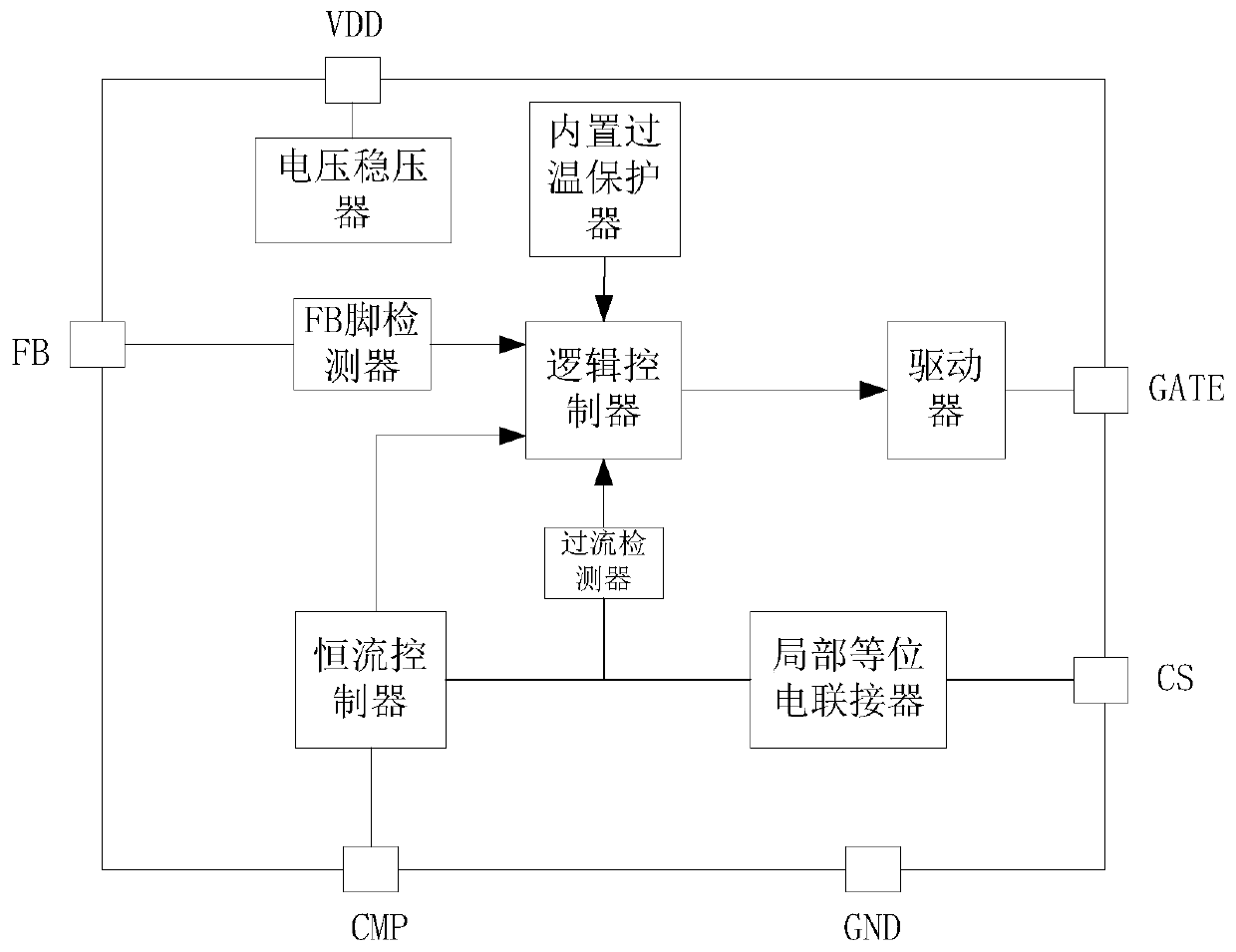

[0036] In a specific embodiment, the first port of the main control chip is connected to the power adjustment module, and the second port of the main control chip is connected to the control module; the frequency adjustment module is used to generate the reference voltage V ref and reference voltage V cs , where the reference voltage V ref Output to the main control chip through the first port, the reference voltage V cs Output to the control module; the main control chip is used to receive the reference voltage V of the power regulation module ref , generate the control model and output it to the control module; the control module is used to pass the reference voltage V ref Generates the reference voltage V cs , and set the reference voltage V cs sent to the transformer equipment. In this embod...

Embodiment 2

[0043] read on figure 1 , embodiment 2 provides an LED drive circuit, the LED lamp drive circuit includes the power output circuit of embodiment 1, and also includes a step-down constant current module, the step-down constant current module is used to store the reference voltage V cs , and send it to the LED lamp after stepping down.

[0044] In a specific embodiment, the step-down constant current module includes a transformer T, a third diode D3, a third capacitor C3, and a discharge resistor; one end of the secondary coil of the transformer T is connected to the anode of the third diode D3, and the secondary The two ends of the coil are sequentially connected with the third capacitor C3 and the discharge resistor, and the two ends of the discharge resistor are respectively connected to the positive input terminal and the negative input terminal of the LED. The transformer T is an isolation transformer, which has a first primary winding, a second primary winding and a second...

Embodiment 3

[0063] Embodiment 3 is provided on the basis of Embodiment 2, and Embodiment 2 also provides an LED lamp driving circuit, the LED lamp driving circuit also includes a dimmer 1, a lightning protection unit 2, an EMI filter unit 3 and a rectification unit 4 ; The dimmer 1, the lightning protection unit 2, the EMI filter unit 3 and the rectification unit are sequentially connected to 4, and the fourth capacitor C4 is connected in parallel between the positive output terminal and the negative output terminal of the rectification unit and grounded.

[0064] The lightning protection unit 2, the EMI filter unit 3 and the rectification unit 4 combine with the main control chip to form a flyback circuit (buckboost circuit), which provides a stable constant current output for the LED light source, wherein: the lightning protection unit 2 is used to absorb the surge generated by the mains terminal The lightning surge signal is reduced to the range that the subsequent circuit can withstand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com