Silent pressing rebound opening and closing structure

An open-close structure, quiet technology, applied in building structures, door/window accessories, wing fan components, etc., can solve the problems of low connection compactness, reduce product service life, affect user experience, etc., to improve the connection The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

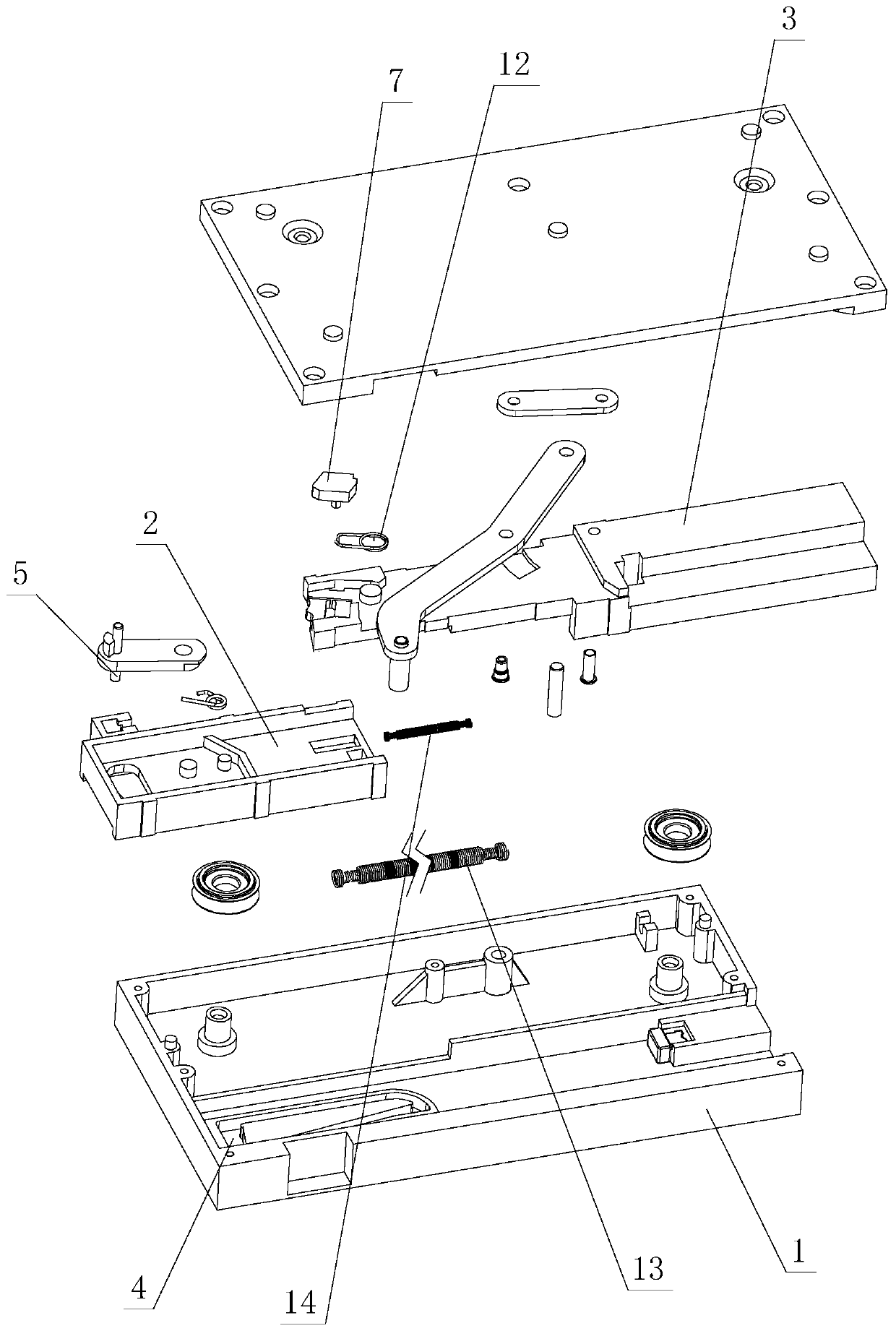

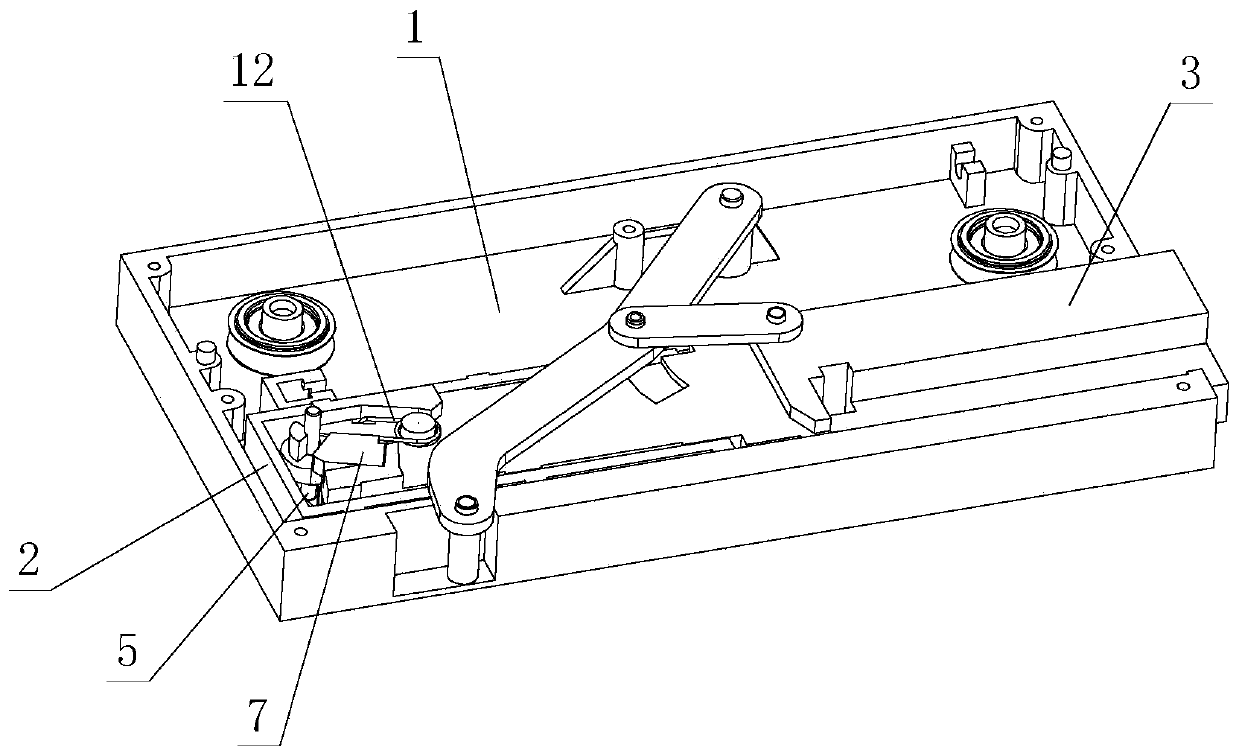

[0036] see Figure 1-Figure 15 , the mute press rebound opening and closing structure, including a rebound bracket 1, a push element 2, a slide element 3, a heart-shaped chute 4 is arranged on the bounce bracket 1, a sliding part 5 is arranged on the push element 2, and through the sliding part 5 Positioning and / or sliding along the trajectory of the heart-shaped chute 4 in a sequential direction, the sliding element 3 is provided with a heart-shaped slide-in guide part 6 and a movable part 7, wherein the sliding element 3 is positioned on the rebound bracket 1 by the positioning of the sliding part 5 Inside and / or sliding on the rebound bracket 1 through the sliding and telescopic sliding of the sliding part 5, the movable part 7 elastically moves on the sliding element 3, and is provided with a heart groove to slide into the buffer part 8.

[0037] When the sliding element 3 slides into the rebound bracket 1, it slides into the guide part 6 through the heart groove and drive...

no. 2 example

[0053] see Figure 16 , Figure 17 , this mute push rebound opening and closing structure is different from the first embodiment in that: the movable part 7 is always elastically rotating and / or swinging in the opposite direction of the heart-shaped stay area 1) through the movable elastic part 12 or the movable elastic part on sliding element 3.

[0054] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com