Continuous surface defect detection device for slender part

A technology for defect detection and parts, which is applied in the field of continuous surface defect detection devices, can solve problems such as unguaranteed detection accuracy, low detection efficiency, and unstable transmission, so as to prevent external light interference, improve success rate, and speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

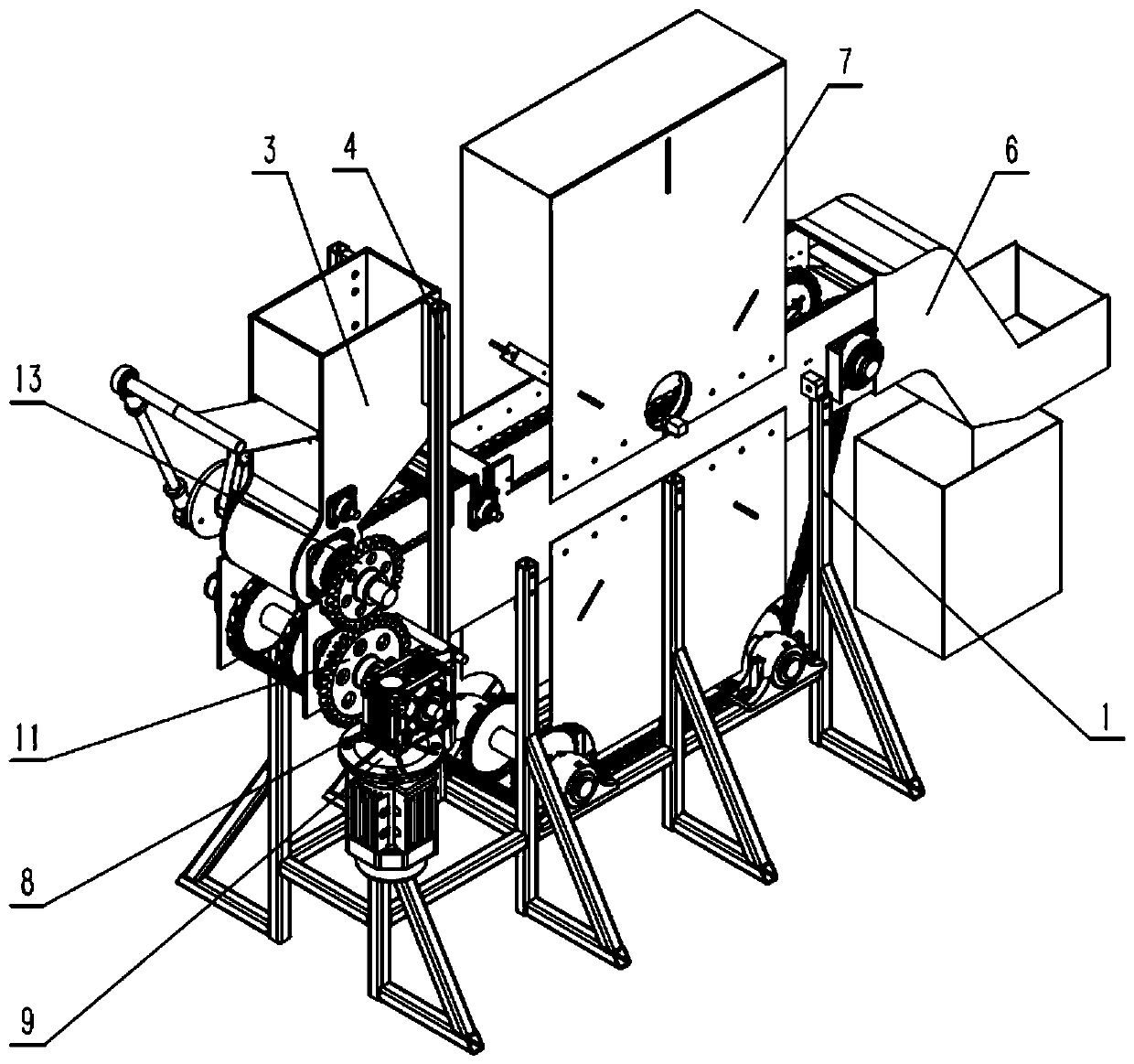

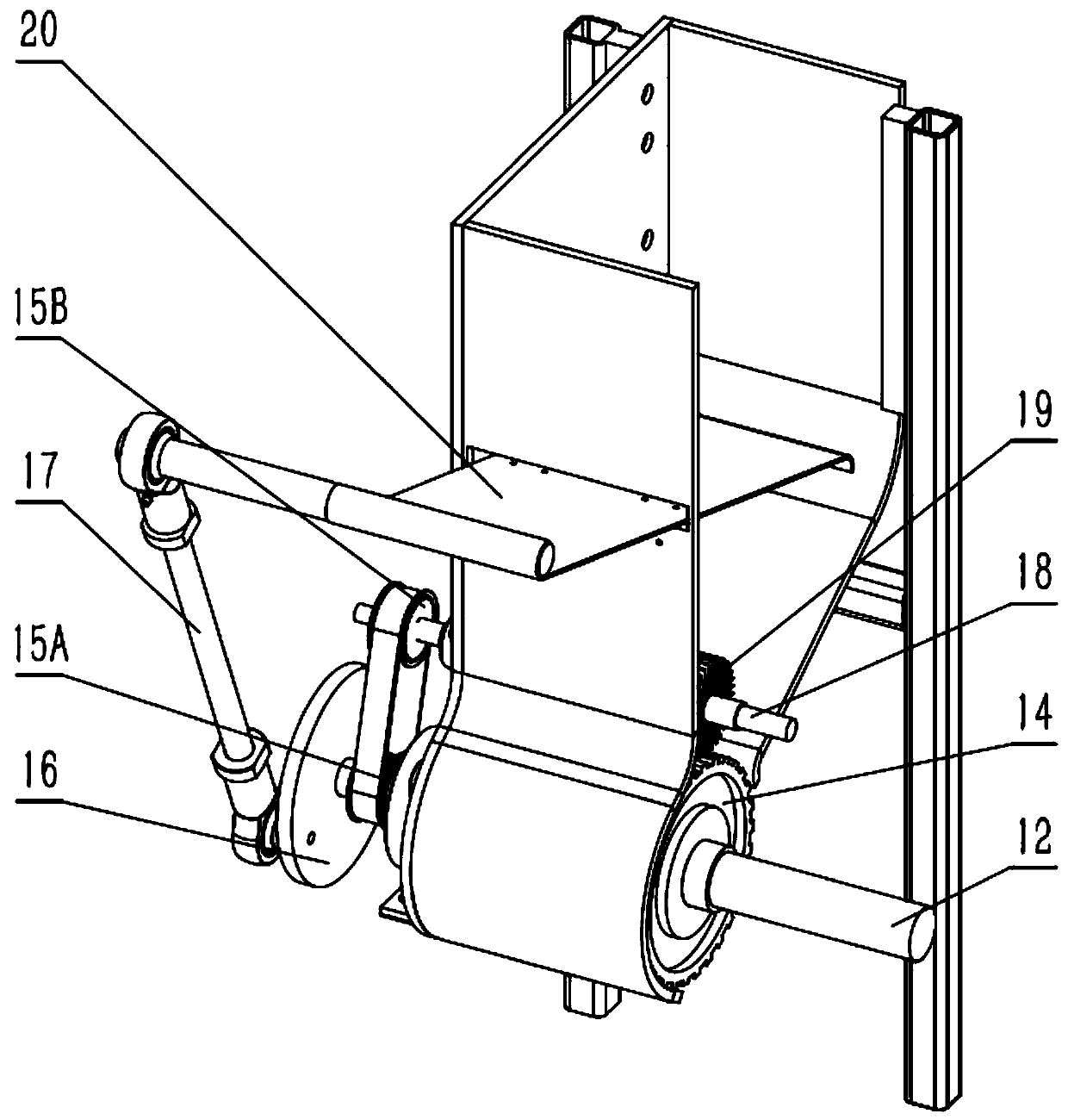

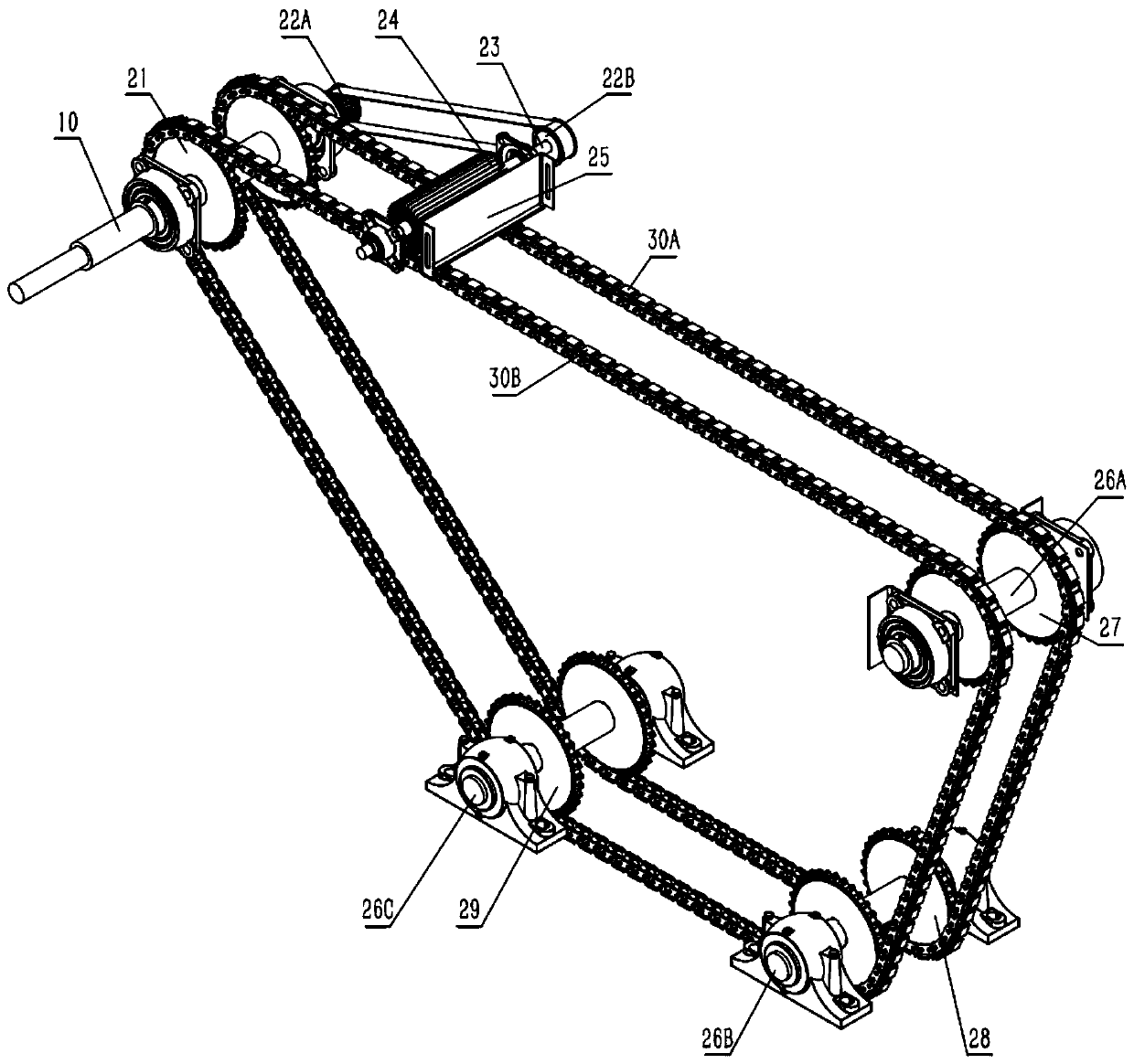

[0021] The invention provides a continuous surface defect detection device for slender parts. The device includes a frame 1, a conveying mechanism, a material box 3, a material box support 4, a blanking mechanism, a screening mechanism 6, a detection mechanism 7, and a reducer 8 , drive motor 9, driving sprocket shaft 10, driving gear 11, running wheel shaft 12, driven gear 13.

[0022]Before work, check the actual situation of the conveying mechanism, check whether it is too loose to affect the actual work, and ensure that there is no foreign object blocking it. Check whether the blanking mechanism works normally to ensure that the vibrating plate 20 can vibrate with the rotation of the crank wheel 16 . Check whether each camera, light source, and motor can work normally. After checking, start the total control system.

[0023] After the detection device is started, the drive motor 9 starts to work, driving the driving sprocket shaft 10 to rotate, and the first feeding chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com