Automatic balancing and locking mold device for lithium battery industry

A technology of automatic balancing and clamping device, applied in non-aqueous electrolyte battery, non-aqueous electrolyte battery, electrolyte battery manufacturing and other directions, can solve the problems of complex structure, difficult operation, slow start and so on, to reduce noise, improve service life, Reduce the effect of die stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

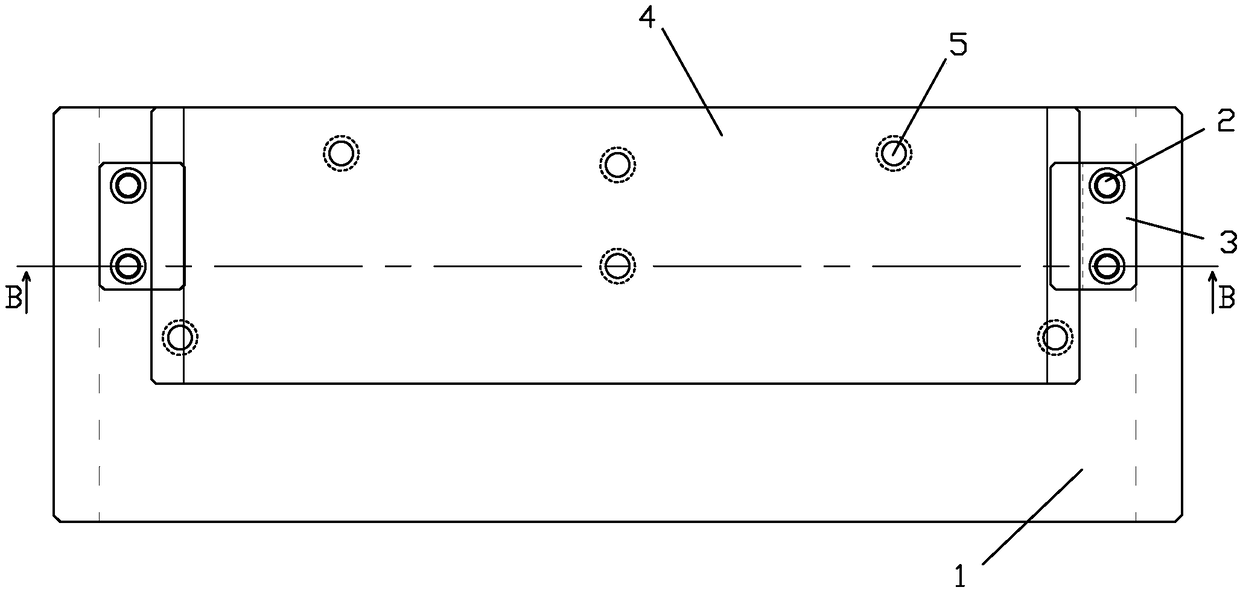

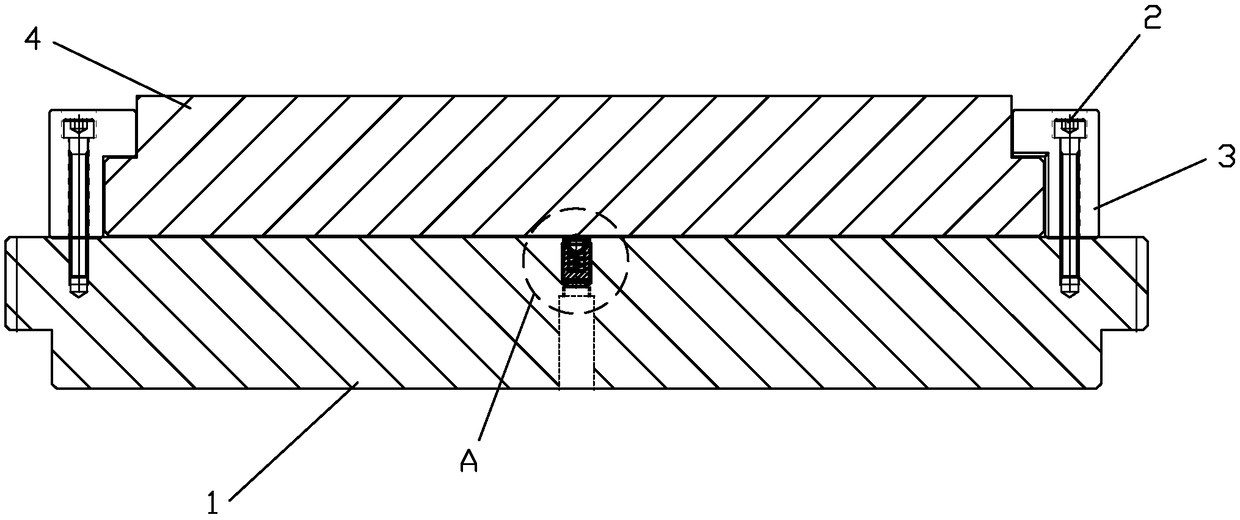

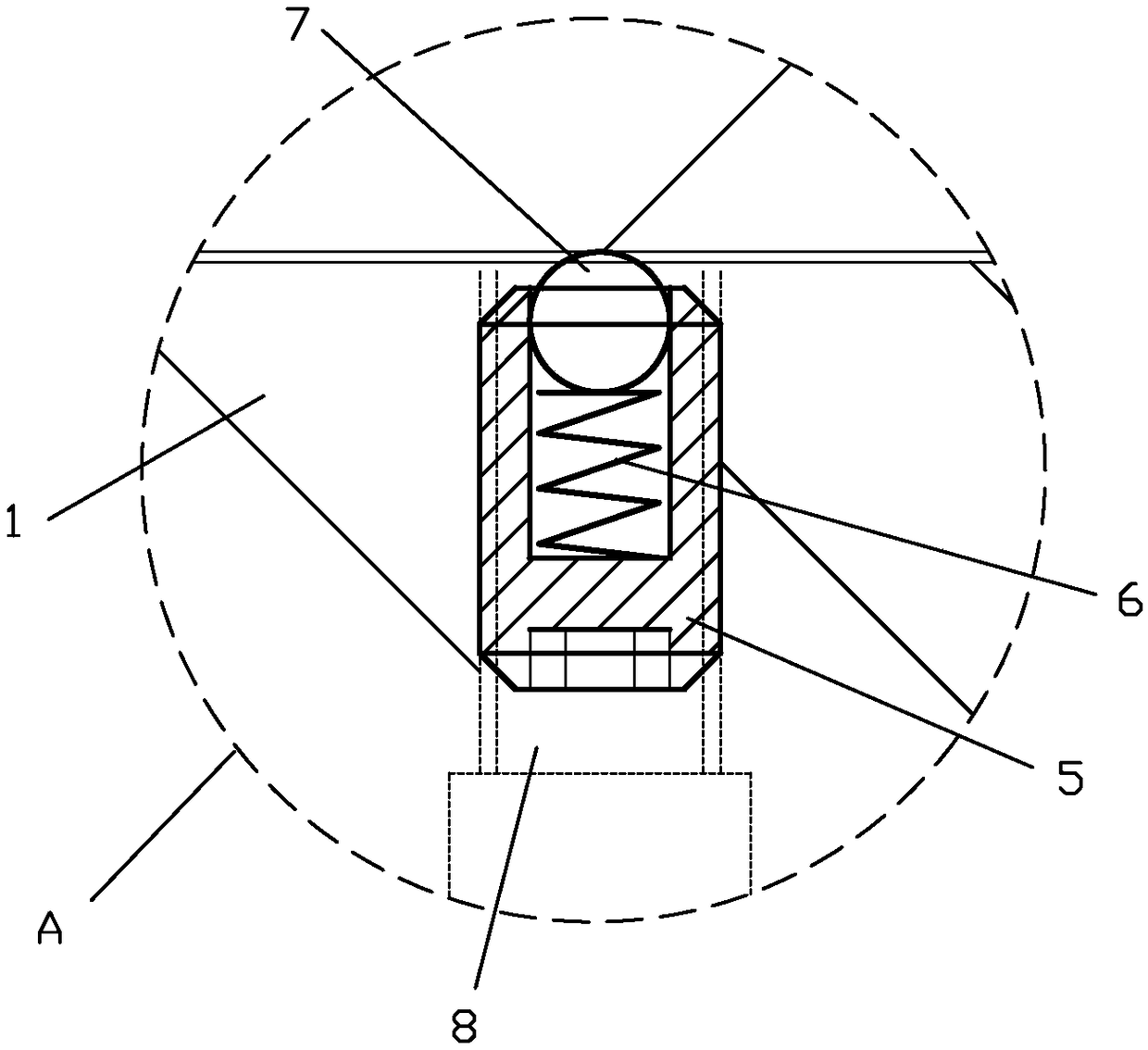

[0018] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: an automatic balance mold clamping device for the lithium battery industry, including an upper mold plate 1 and an upper mold mounting plate 4 fixedly connected to the driving equipment, and the two ends of the upper side panel of the upper mold plate 1 A locking piece 3 is connected by two fixing bolts 2, and the upper mold plate 1 is detachably connected with the upper mold mounting plate 4 through the locking piece 3, and the lower surface of the upper mold mounting plate 4 is connected with the upper mold plate 1 There is a movable gap between the upper surfaces of the upper template 1, and a plurality of screw holes 8 are provided on the upper template 1, and plungers 5 are arranged in the screw holes 8 one by one, and a spring 6 is arranged in the plunger 5, so that The end of the spring 6 close to the upper mold mounting plate 4 is connected with a steel ball 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com