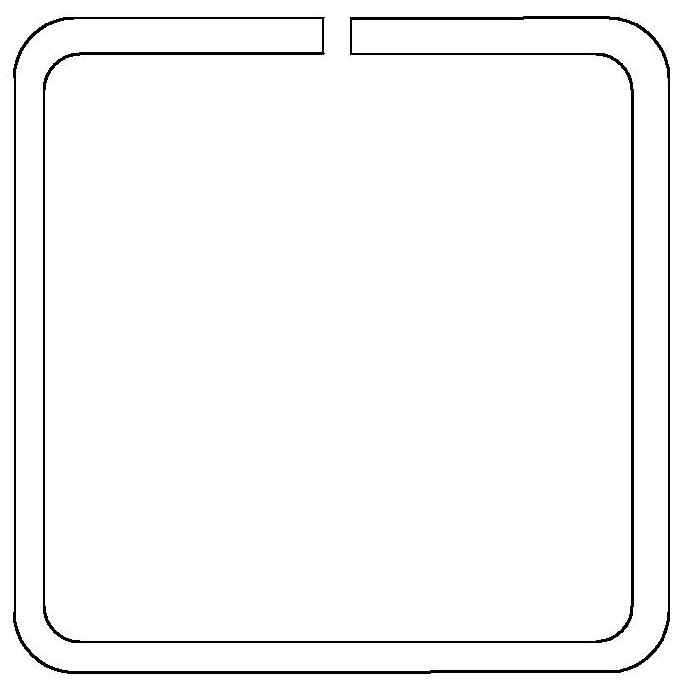

Equipment for automatically producing square-ring-shaped blade

A technology for producing squares and blades, which is applied in the field of stamping equipment, can solve the problems of large deviation, low efficiency, and low precision of square ring blades, and achieve high production efficiency, improve production efficiency, and reduce equipment jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

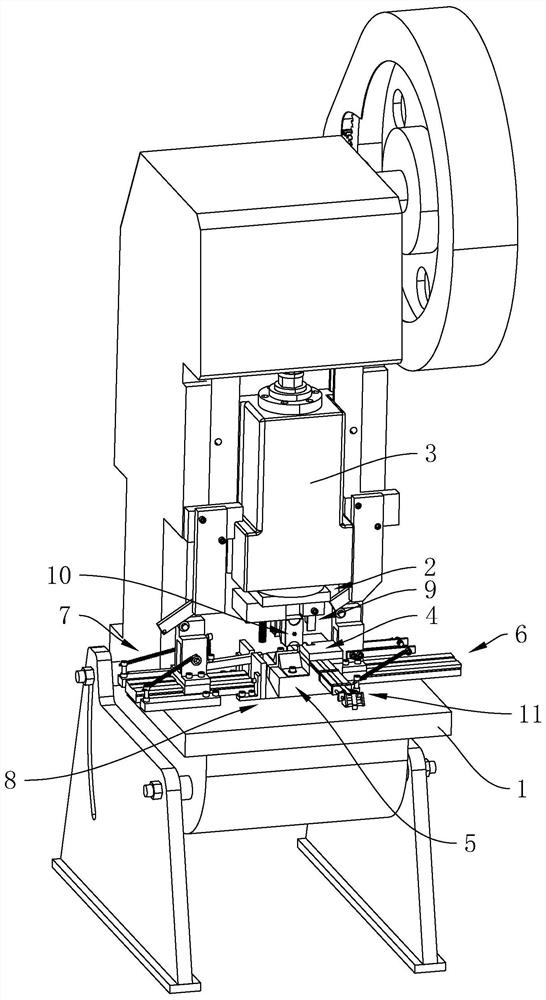

[0048] The following is attached Figure 2-11 The application is described in further detail.

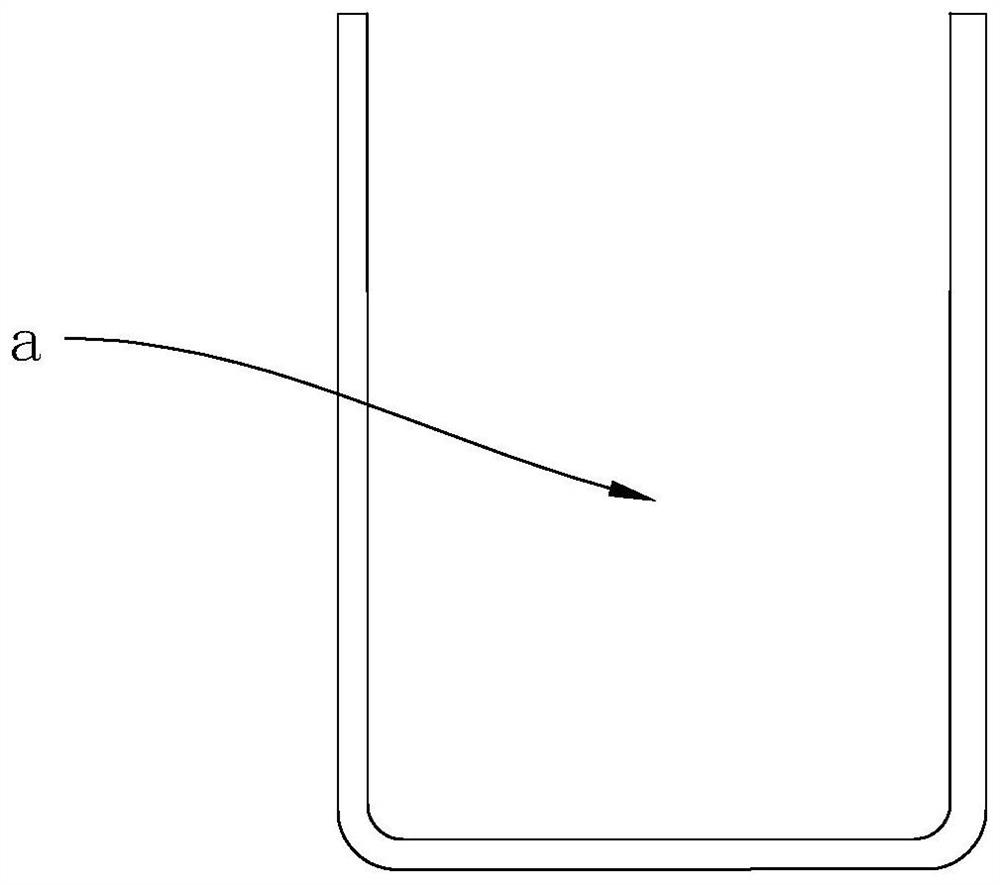

[0049] The embodiment of the present application discloses a device for automatic production of circular blades. refer to figure 2 , which includes a punching machine, a punching and bending station 4 and a top leveling station 5 arranged in sequence on the lower die 1 of the punching machine, and a side of the punching and bending station 4 away from the top leveling station 5 The jacking mechanism 6, the pumping mechanism 7 arranged on the side of the top leveling station 5 away from the punching and bending station 4, the unloading mechanism 8 arranged between the top leveling station 5 and the pumping mechanism 7, The forming mechanism arranged on the upper die 2 of the punch press and the feeding mechanism 11 for feeding to the punching and bending station 4.

[0050] Wherein, the forming mechanism includes a punching and bending device 9 adapted to the punching and bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com