Monitoring print heads in random manner

A printing head, a printing head technology, applied in printing and other directions, can solve the problems of limited printing nozzle detection and compensation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

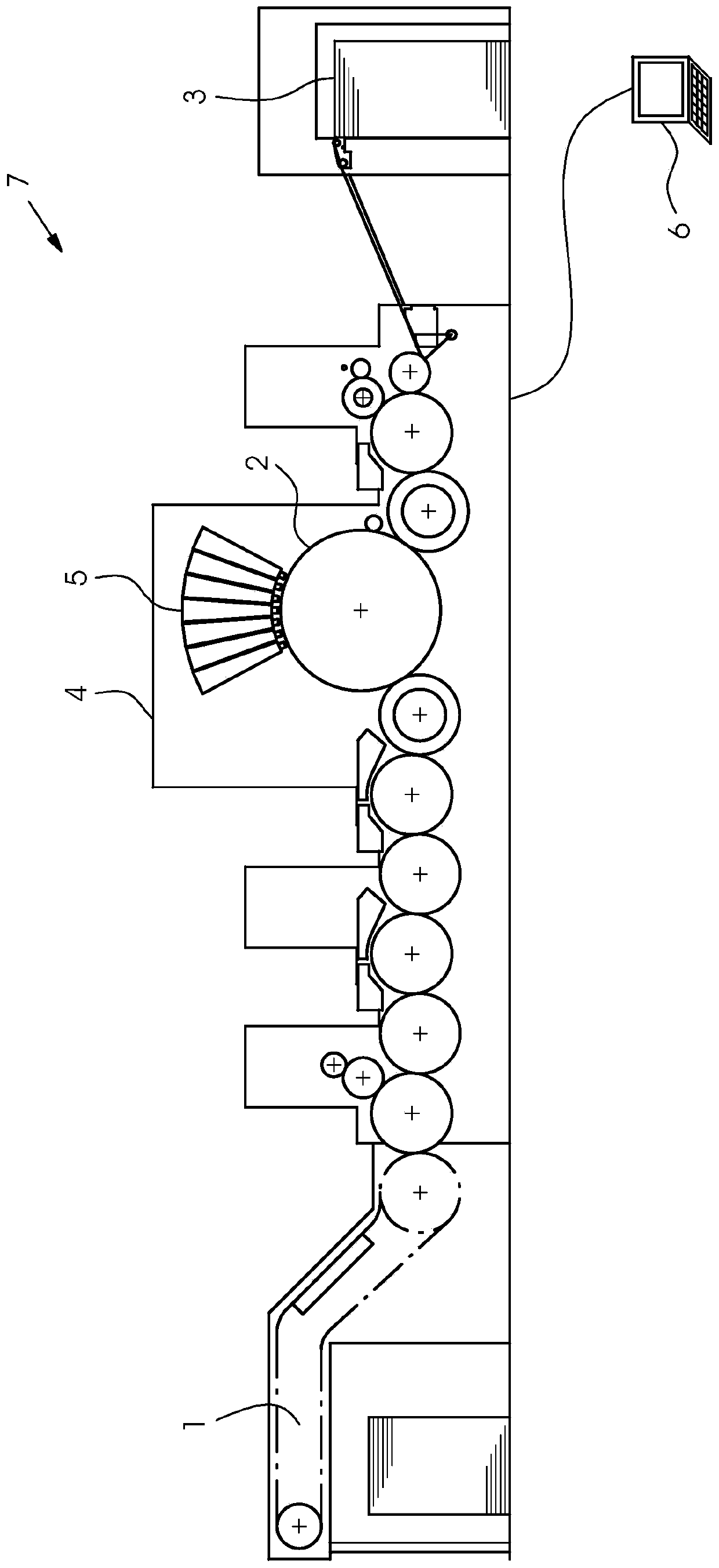

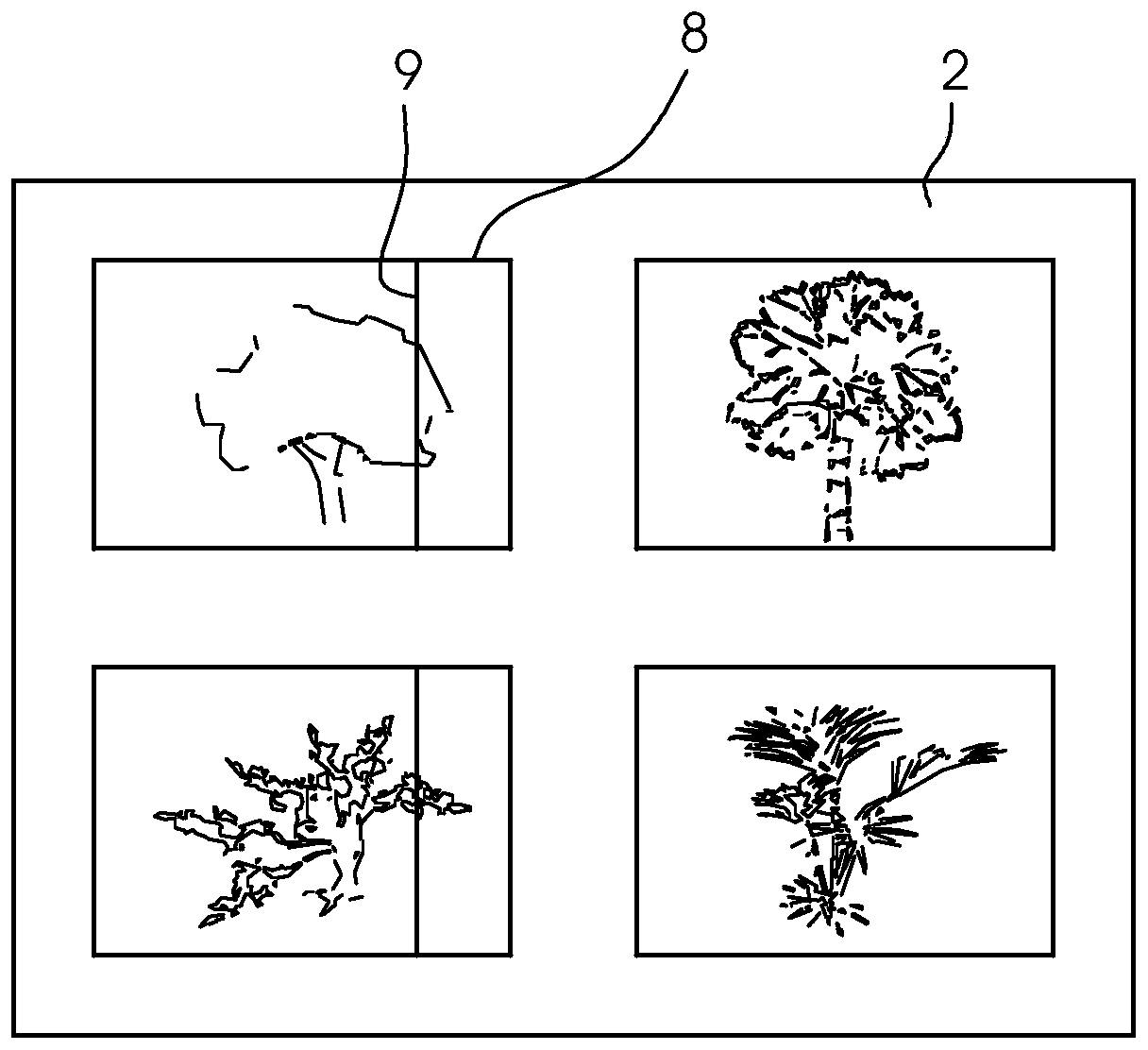

[0031] The field of application of this preferred embodiment variant is inkjet printers 7 . figure 1 An example of the basic structure of such a machine 7 comprising a feeder 1 for feeding a printing substrate 2 into a printing mechanism 4 where it is printed by a printing head 5 and even a receiver is shown in Feeder 3. This is a sheet inkjet printing press 7 controlled by a control computer 6 . As already described, it may occur during operation of the printing press 7 that individual printing nozzles in the printing heads 5 of the printing unit 4 fail. The consequence is then "white lines" 9, or in the case of multicolor printing, distorted color values. figure 2 An example of such a "white line" 9 in a printed image 8 is shown in .

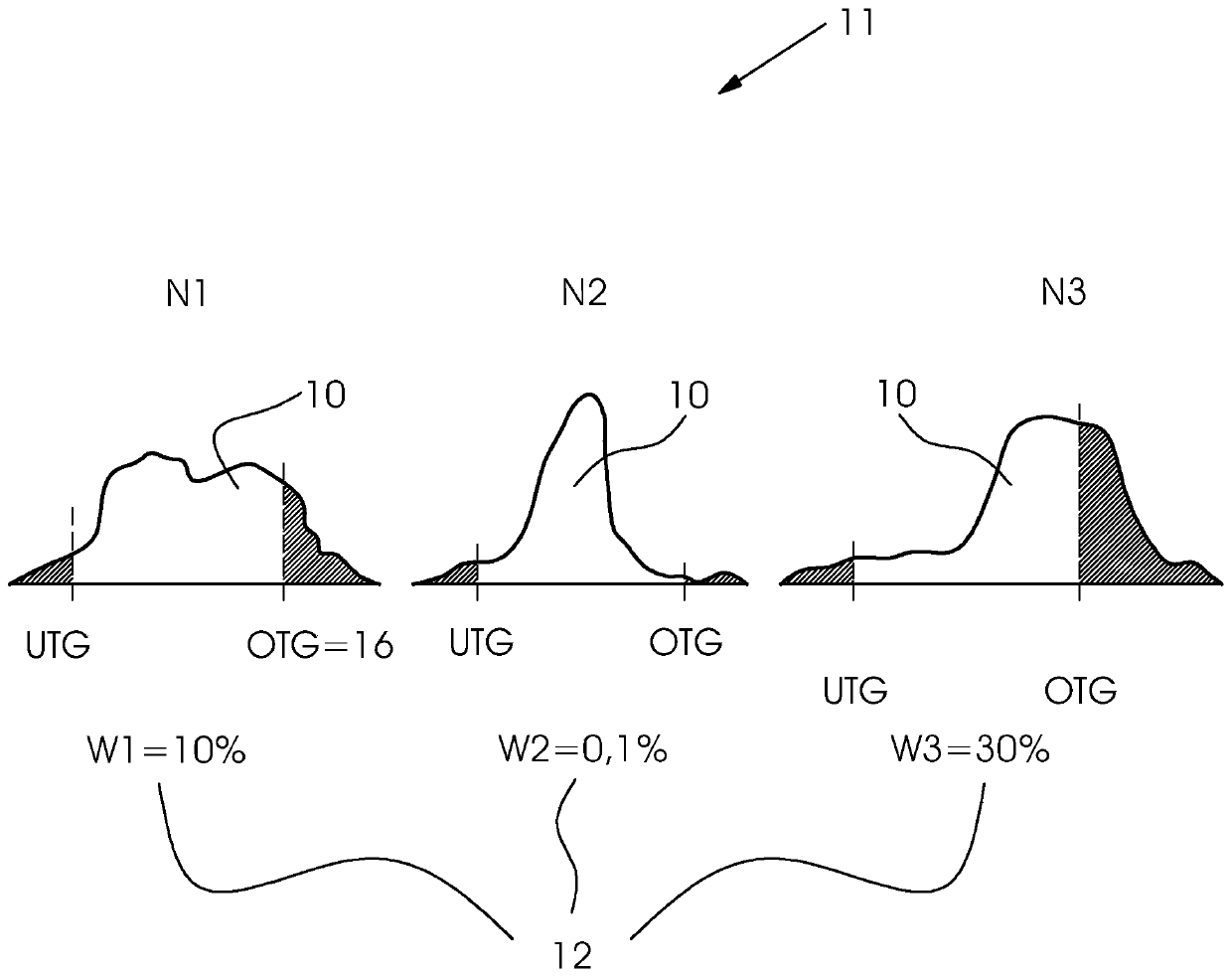

[0032] The method according to the invention is based on the optimal determination of the threshold values in a weighted manner as disclosed in the prior art, which are determined by means of a statistical prediction model based on past ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com