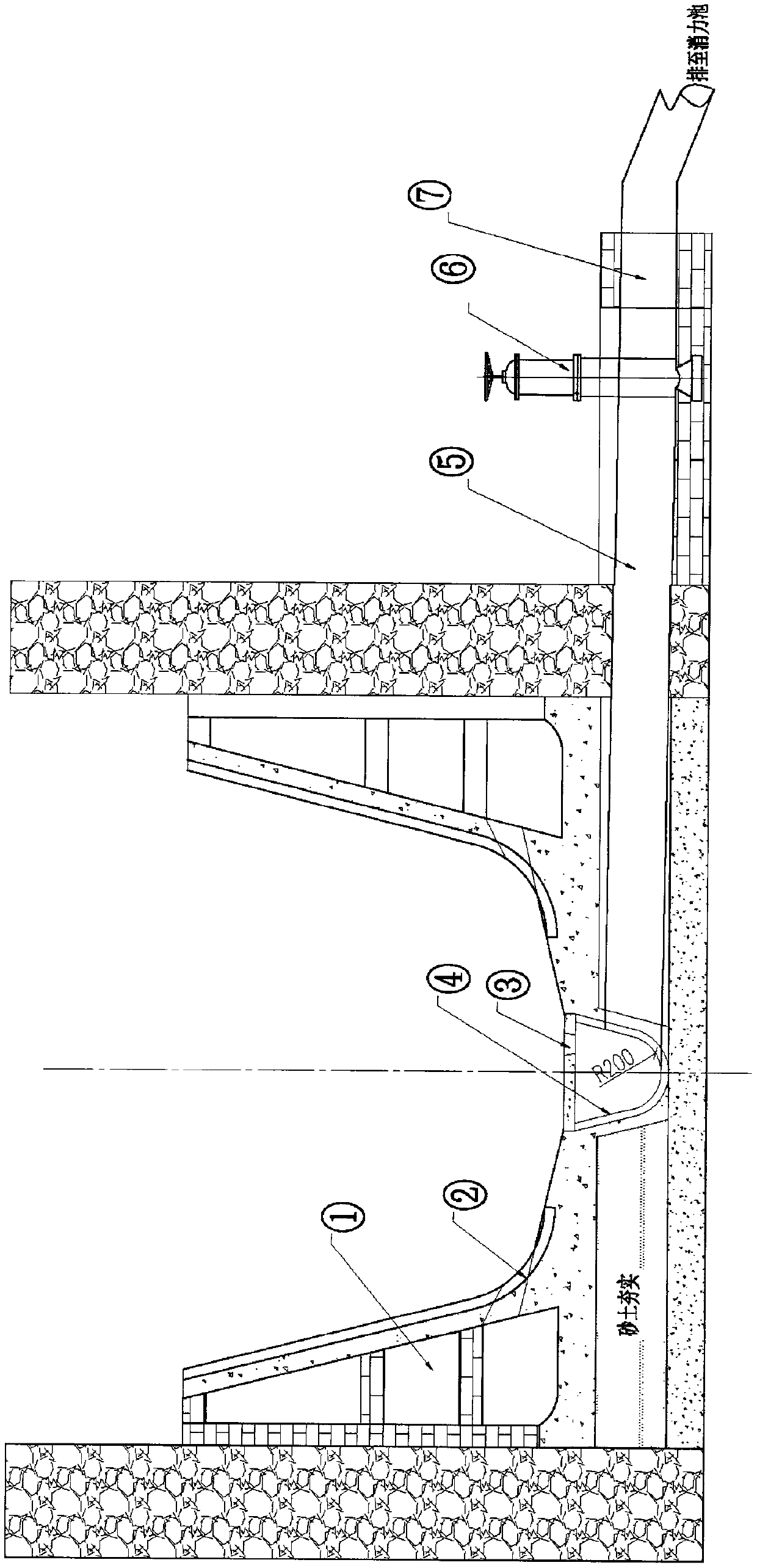

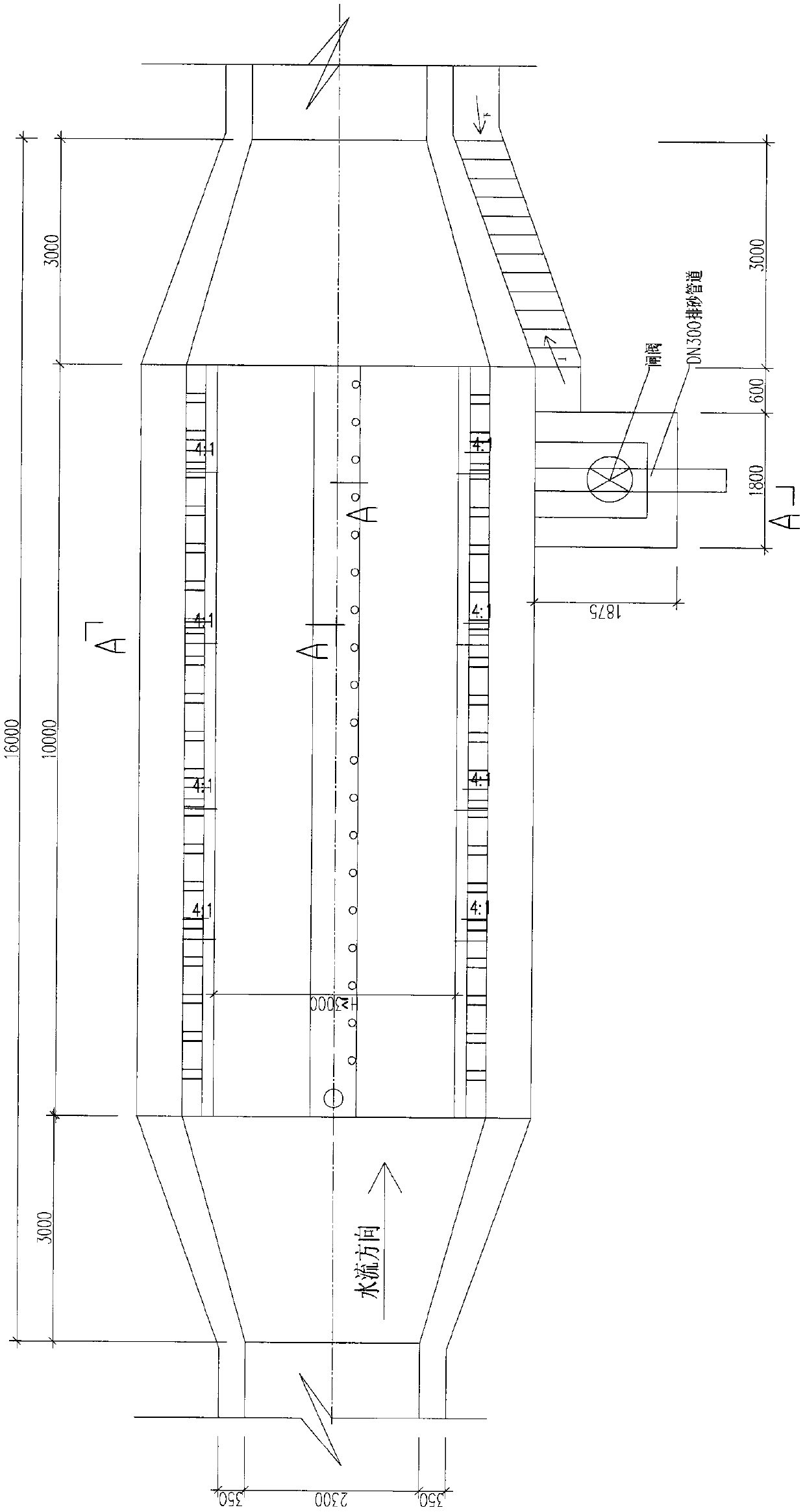

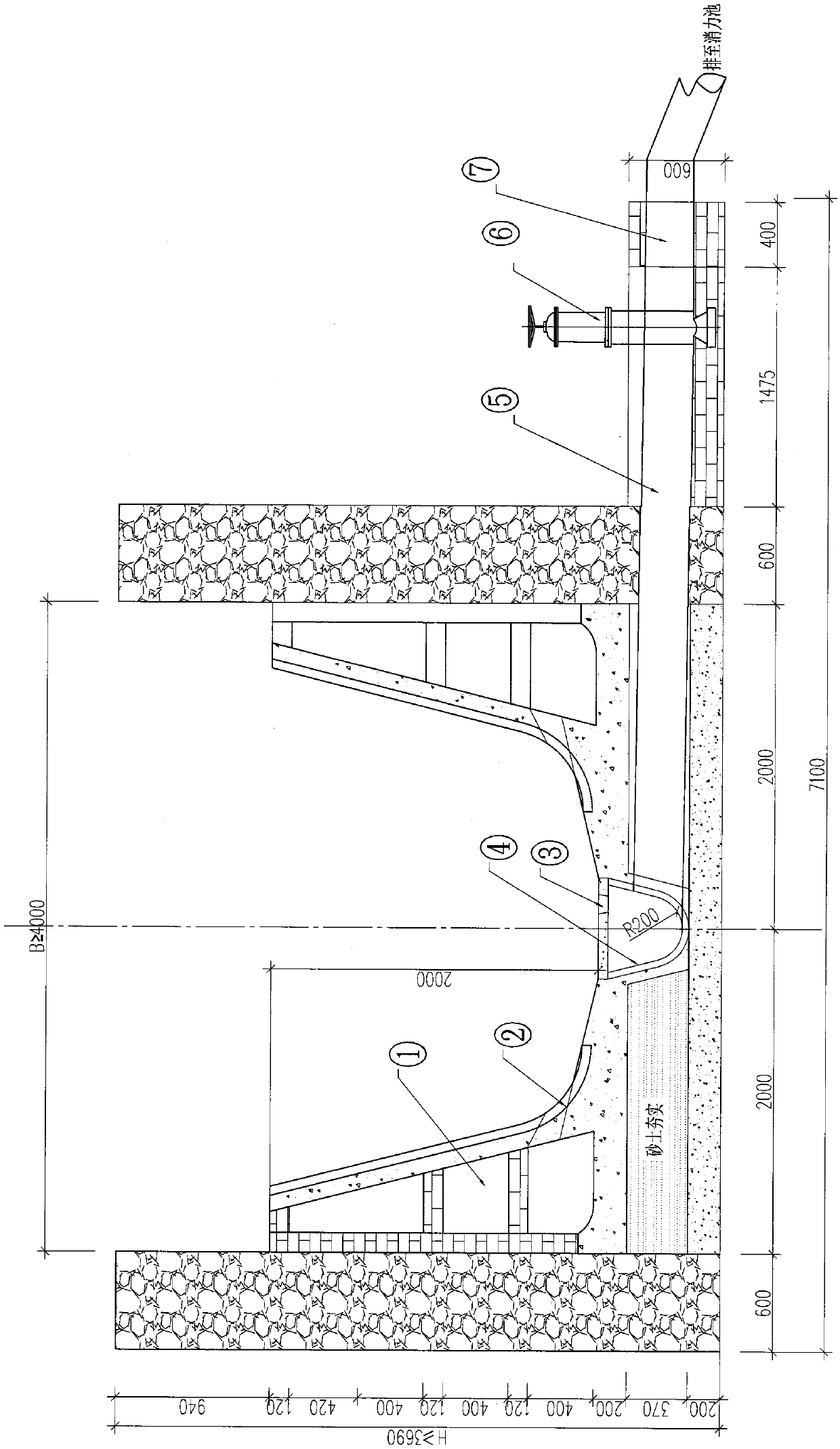

Hydrodynamic linkage scouring and desilting facility

A technology of hydropower and facilities, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems that silt and sand cannot be smoothly removed and affect the normal operation of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The side of the grit chamber is constructed with semi-U-shaped components, and the bottom of the water tank is provided with a hole with a large inside and a small outside every 500 mm, which generates clustered water flow to push the sand on the side of the grit chamber to the middle of the grit chamber. The orifice vortex water flow vortex in the middle of the pool is arranged every 500mm to pull the bottom sand to the full U-shaped sand discharge pipe, and the rotary cutting water flow generated by the full U-shaped sand discharge pipe is transported to the siphon sand discharge pipe, and the siphon sand discharge pipe The siphon effect increases the sand discharge capacity and removes the silt and sand in the sedimentation tank.

[0020] The technical scheme that the technical problem that the technical invention of the present invention solves adopts is: build half U-shaped trough wall (also can build the structure of similar shape with prefabricated concrete U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com