A distribution plate that can distribute different flow differences

A valve plate and flow difference technology, which is applied to the components of the pumping device for elastic fluids, pump elements, liquid fuel engines, etc., to achieve the effect of great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

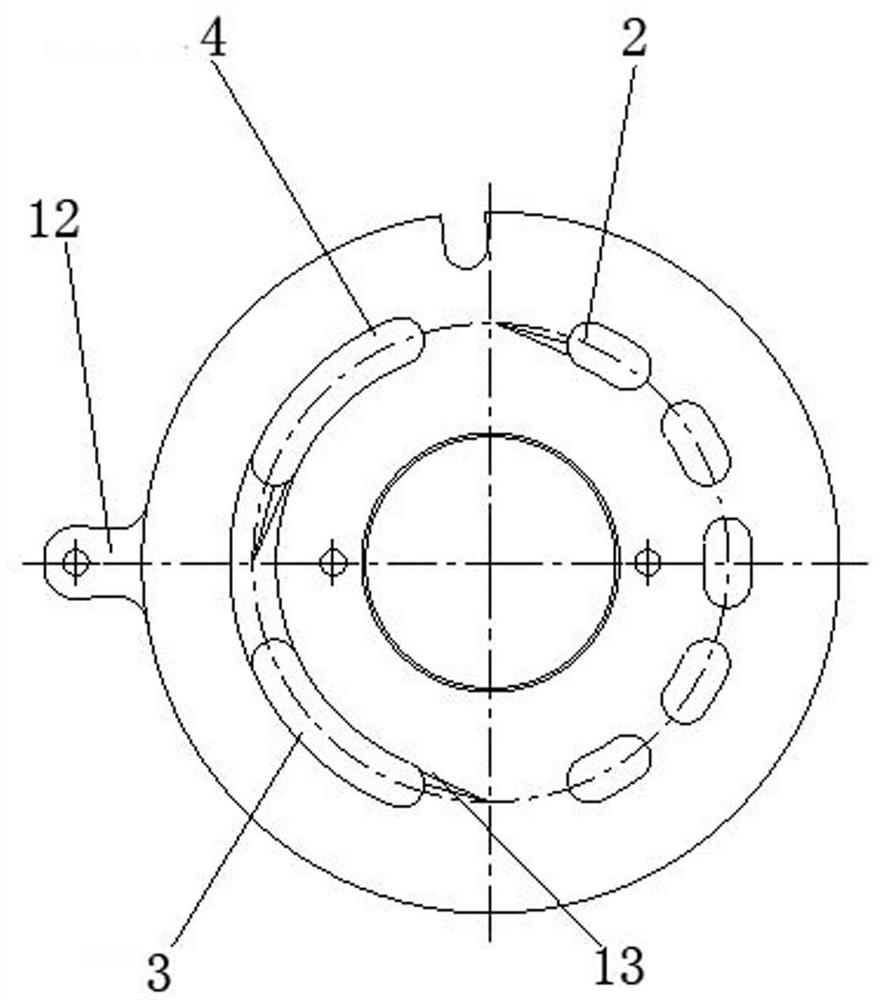

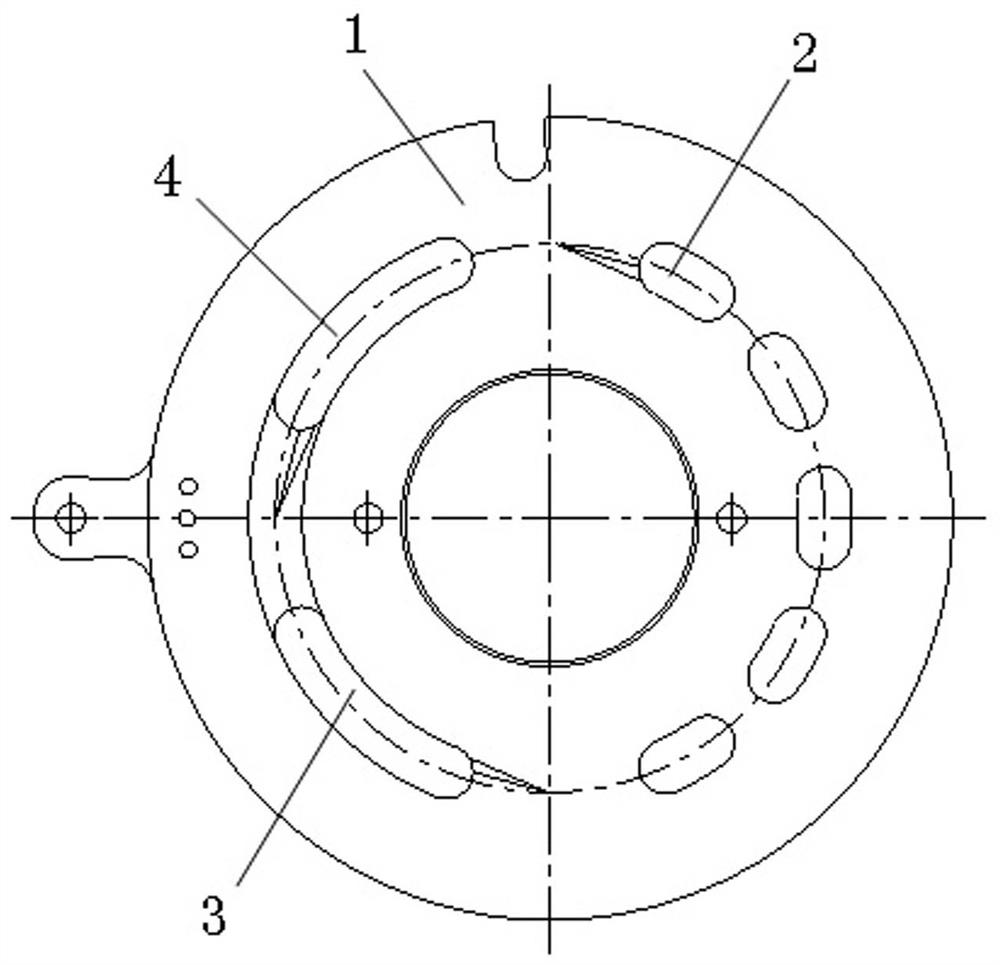

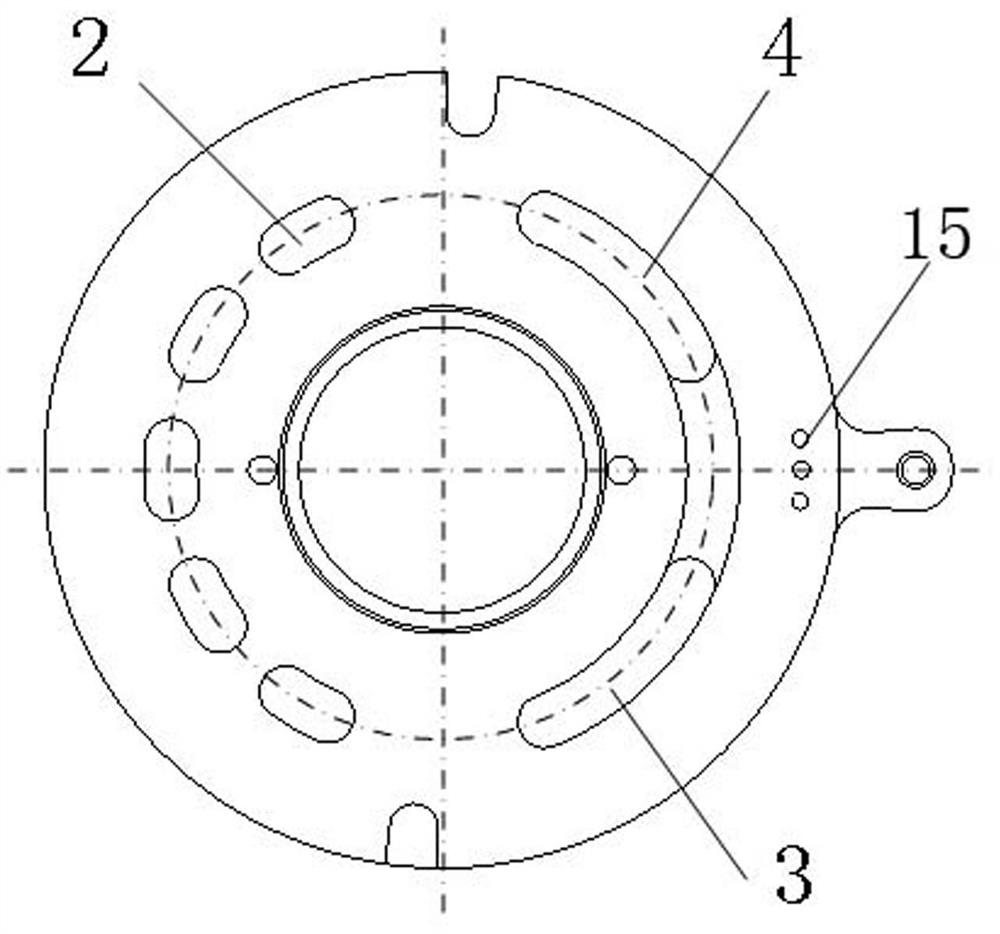

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings. It should be pointed out that the descriptions of specific embodiments in this section should not be considered as having any limiting effect on the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments may provide further evidence for the claims, where there is no conflict.

[0028] A flow distribution plate capable of distributing different flow differences according to the present invention specifically includes: a plurality of oil suction windows C2 and two oil discharge windows on the flow distribution plate, wherein the two oil discharge windows include: A oil discharge window 3, B oil discharge window window 4. The oil suction window C, the oil discharge window A, and the oil discharge window B are all arc-shaped waist holes, and the three flow distribution windows are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com