Chip recording machine capable of automatically feeding and blanking

A technology of automatic loading and unloading and burning machine, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc. Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

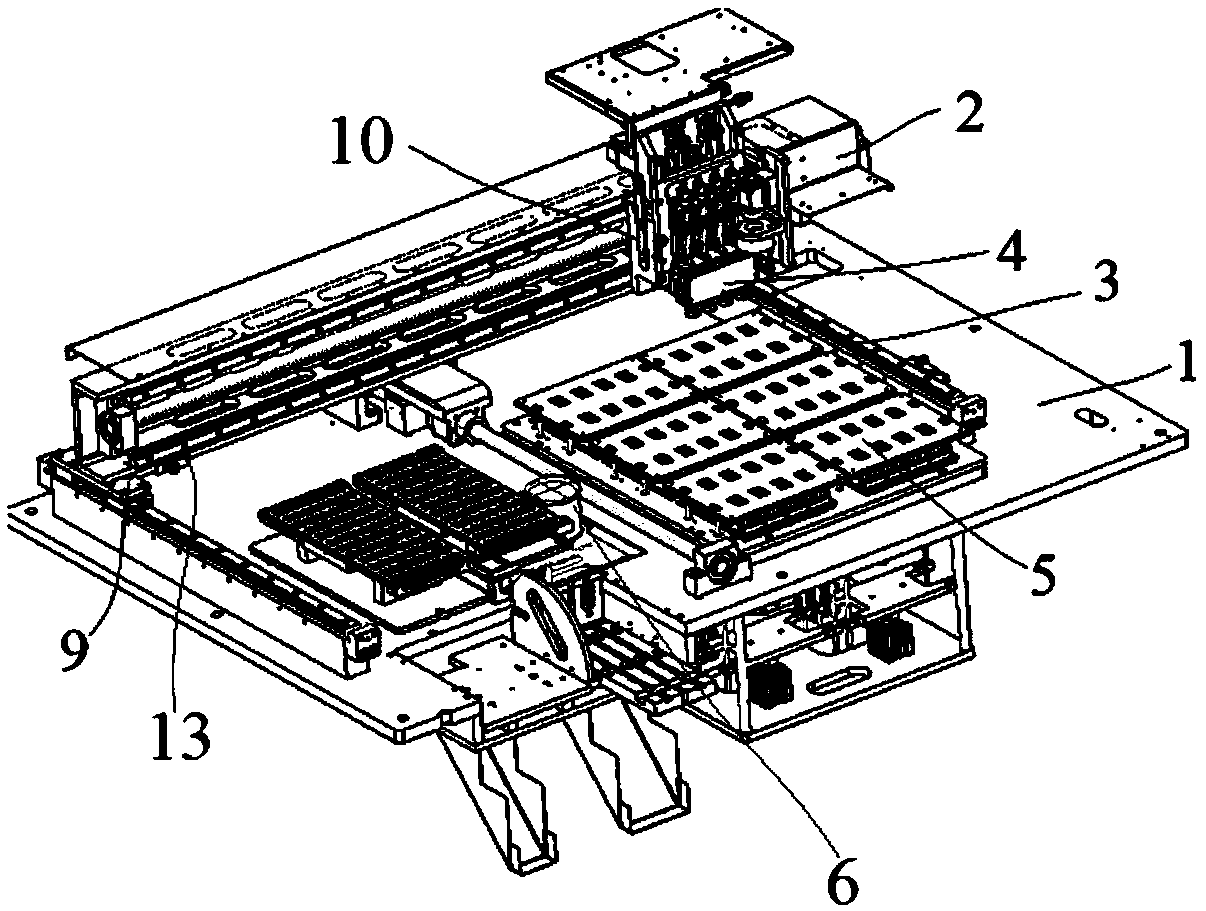

[0042] Embodiment 1: A chip programming machine capable of automatic loading and unloading, including a substrate 1, an X-axis driving mechanism 2, a Y-axis driving mechanism 3, a material suction mechanism 4 and a programming mechanism 5, and the Y-axis driving mechanism 3 is set On the upper surface of the substrate 1, the X-axis driving mechanism 2 is installed and connected with the Y-axis driving mechanism 3 through several XY connecting blocks 9 and can reciprocate in the Y-axis direction, and the suction mechanism 4 is movably installed through the XZ connecting blocks 10 On the X-axis drive mechanism 2 and can reciprocate along the X-axis direction, the burning mechanism 5 is installed on the substrate 1 and located below the suction mechanism 4;

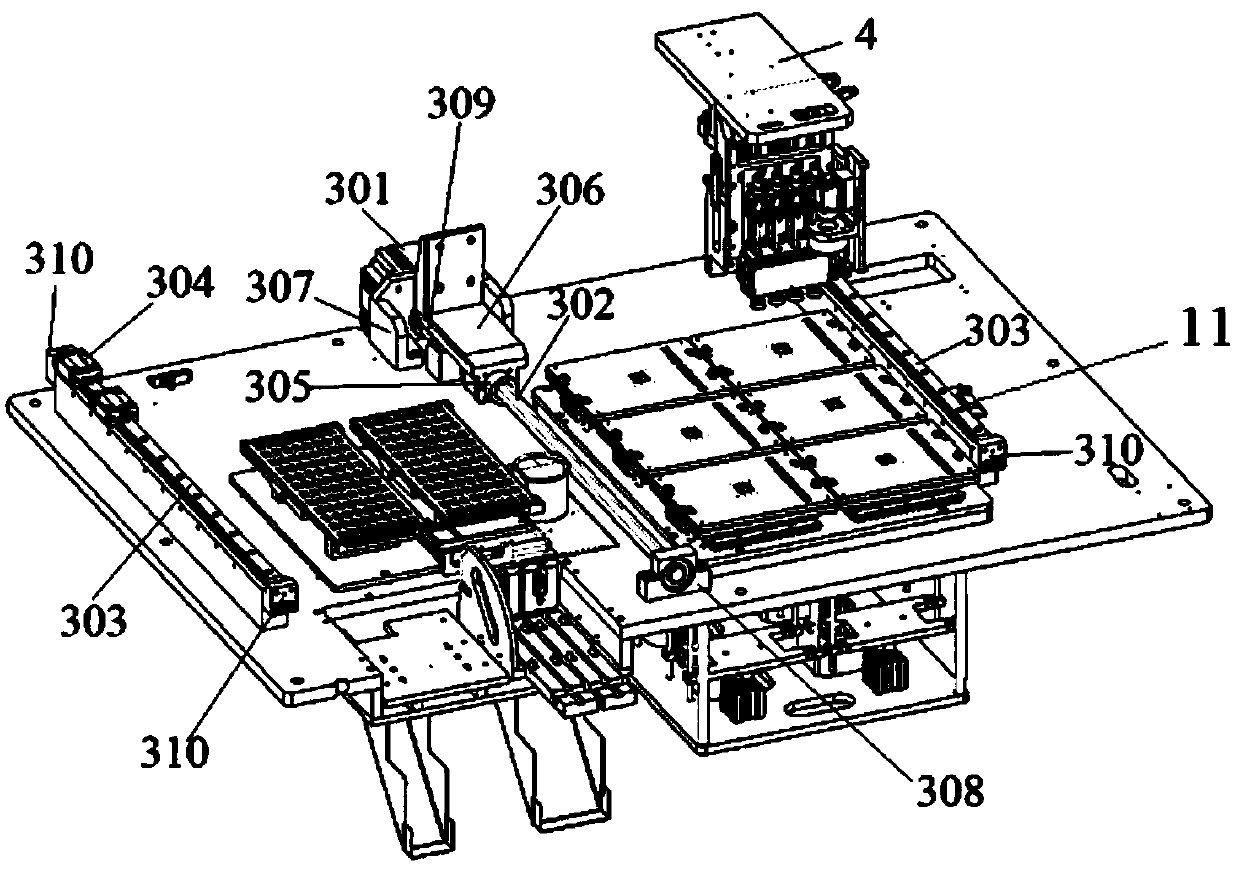

[0043] The Y-axis drive mechanism 3 further includes a Y-axis motor 301, a Y-axis screw 302 connected to the Y-axis motor 301, at least one Y-axis slide rail 303, and several Y-axis sliders movably mounted on the Y-axis slide...

Embodiment 2

[0054] Embodiment 2: A chip programming machine capable of automatic loading and unloading, including a substrate 1, an X-axis driving mechanism 2, a Y-axis driving mechanism 3, a suction mechanism 4 and a programming mechanism 5, and the Y-axis driving mechanism 3 is set On the upper surface of the substrate 1, the X-axis driving mechanism 2 is installed and connected with the Y-axis driving mechanism 3 through several XY connecting blocks 9 and can reciprocate in the Y-axis direction, and the suction mechanism 4 is movably installed through the XZ connecting blocks 10 On the X-axis drive mechanism 2 and can reciprocate along the X-axis direction, the burning mechanism 5 is installed on the substrate 1 and located below the suction mechanism 4;

[0055] The Y-axis drive mechanism 3 further includes a Y-axis motor 301, a Y-axis screw 302 connected to the Y-axis motor 301, at least one Y-axis slide rail 303, and several Y-axis sliders movably mounted on the Y-axis slide rail 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com